The onboard environmental control system has become an important part of protecting the safety of people on board and providing a comfortable environment since the advent of the aircraft. With the gradual increase in the altitude of the aircraft and the continuous advancement of science and technology, the onboard environmental control system has also developed more advanced and intelligent, making our flight more comfortable

Leather jacket goggles, passive insulation

In the troposphere, the temperature and air pressure continue to decrease with the increase in altitude. The cockpits of early aircraft were mostly open, with only a few windshields at most, so pilots had to face the cold and biting wind. Such a cockpit environment was not only not comfortable but also very easy to cause human body hypothermia. In this case, the way pilots kept warm and windproof at that time was relatively simple and crude-wearing leather coats and goggles. Although this method can keep out the cold, it cannot actively replenish the heat for the pilots, but can only passively reduce the loss of heat.

As the aircraft’s flying altitude continues to increase, the oxygen concentration becomes lower and lower, and it becomes more and more difficult for pilots sitting in the open cockpit to breathe, so the air pressurization oxygen supply system becomes an urgent need for pilots.

The advent of onboard oxygen supply, pressurization, and heating

During the war, the preparation technology of high-pressure oxygen had matured, and the air separation process could provide a large amount of high-pressure oxygen for cabin oxygen supply. The initial cabin oxygen supply measure was very simple: the pilot would hold the hose connected to the oxygen generator directly in his mouth and breathe. The oxygen mask that came out later not only effectively improved the airtightness and reduced oxygen waste, but also improved the pilot’s comfort. This oxygen supply method has continued to this day and still plays an irreplaceable role in military aircraft and emergency oxygen supply.

In order to better block airflow, improve the comfort of cabin personnel and maintain cabin temperature, a closed aircraft cabin was born. However, the closed cabin did not meet the airtightness standard at first and could only serve as a windbreak, so crew members still needed to breathe oxygen when performing high-altitude missions. It was not until the 1930s and 1940s that some large aircraft, represented by Boeing 307 passenger aircraft and B-29 bomber, began to install airtight pressurized cabins, using high-pressure air from special cabin superchargers or engine superchargers to pressurize the cabin. Aircraft with this design can also maintain a high air pressure at high altitudes, freeing the crew from the constraints of oxygen masks.

In order to avoid hypothermia of the crew on board, combustion heaters, electric heaters and engine exhaust heaters have been introduced one after another. Among them, the combustion heater that relies on fuel combustion for heating has a large heating power, but it requires additional fuel consumption and is mostly used for small aircraft in cold areas; the electric heater is easy to arrange, but it needs to consume precious electricity on the aircraft, and is mostly used for windshield heating and auxiliary heating. The engine exhaust heater does not consume additional energy and can transfer the waste heat contained in the engine exhaust gas to the cabin air through a heat exchanger, realizing the transformation of waste into treasure, but the disadvantage is that it cannot provide heating when the aircraft engine is turned off. The B-29 bomber at the end of World War II used an engine exhaust heater as a cabin heat source. To achieve controllable cabin temperature, the designer added a ram air heat exchanger and a ram air valve to the heater outlet. The valve can control the heat exchange between hot air and the ram cold air outside the aircraft, thereby adjusting the temperature of the hot air input into the aircraft.

The advent of this device allows crew members to get rid of heavy flight suits and work in the cold 10,000-meter altitude wearing only a thin shirt. It solves the comfort problem of high-altitude flight to a certain extent, but when the aircraft is flying at low altitude and low speed or even parked on the ground, the hot air near the ground, solar radiation and various airborne equipment will become harmful heat sources for the cabin air, causing the cabin temperature to be too high, which also affects the comfort of the passengers. In order to dissipate heat for the passengers, some Russian aircraft choose to install electric fans above the cockpit, while more modern large and medium-sized civil aircraft choose to install large-scale airborne air conditioning systems with a power of up to hundreds of kilowatts.

Cool and warm as you like - the birth of modern passenger aircraft air conditioning system

The turbojet engines, turboprop engines and turbofan engines that appeared after the war are all powerful, and their compressor power far exceeds the turbine or mechanical supercharger of the piston engine. Therefore, the compressor bleed air can not only meet the needs of cabin pressurization, but also serve as the working medium and power source of the large air conditioning system on board.

Of course, in addition to relying on the main engine compressor to provide air conditioning working air source, most commercial aircraft can also use auxiliary power units (APUs) to provide bleed air when they are parked on the ground. This device is essentially a small gas turbine, but its power is much smaller than that of the aircraft engine, so it can significantly save energy. After boarding the plane, we sometimes smell an unpleasant fuel smell in the cabin. This is because the APU bleed air used in the air conditioning system contains a trace amount of leaked lubricating oil-of course, due to the negligible concentration, it does not affect health. The Boeing 787 "Dreamliner" has eliminated the bulky and complex bleed air system and replaced it with an all-electric system. The air conditioning air source of this aircraft comes from a dedicated electric compressor. Although the weight increases, the elimination of bleed air improves engine efficiency and ultimately reduces fuel consumption by about 5%. In addition, since there is no gas exchange between the air conditioning system and the APU, the cabin odor caused by the above-mentioned oil leakage has almost disappeared.

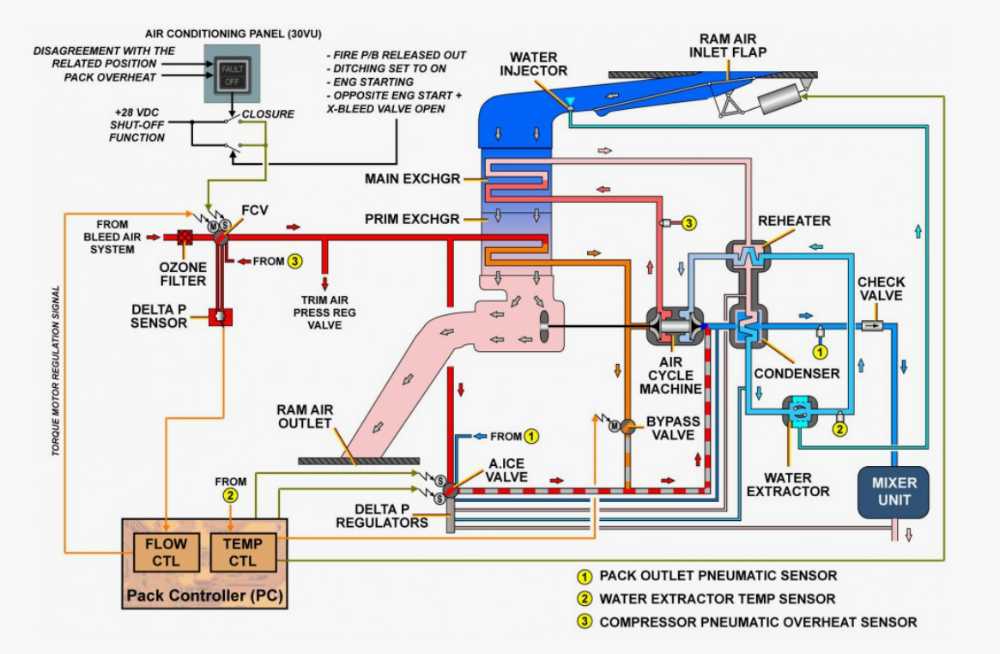

The high-pressure air from the above-mentioned various air sources will eventually be sent to the aircraft air conditioning assembly, which mainly includes a ram air channel, a set of coaxially mounted expansion turbines and centrifugal compressors, a reheater and a condenser (these two components are essentially heat exchangers), and the ram air channel is equipped with a cooling fan connected to the main shaft of the expansion turbine, a primary heat exchanger and a secondary heat exchanger. In this assembly, the high-pressure air and the normal temperature ram air from outside the aircraft will cleverly complete expansion, compression, heat exchange and mixing, and finally be adjusted to the appropriate temperature.

Precooling and compression:

The high-temperature high-pressure air first enters the ram air channel, is cooled by normal temperature air in the primary heat exchanger, and then enters the centrifugal compressor and secondary heat exchanger to complete compression and secondary cooling.

Gradual condensation:

Then, the high-pressure air first exchanges heat with the cold high-pressure air leaving the condenser in the regenerator; then enters the condenser and exchanges heat with the cold low-pressure air after turbine expansion, and condenses water in the process.

Separation of moisture:

In order to prevent frost inside the expander and condenser, resulting in poor air flow, a water separator is also installed after the condenser to separate the condensed water droplets carried in the cold high-pressure air. The condensed water produced by the water separator will also be fully utilized and transported to the water nozzle located in the ram air channel, where it is re-atomized to cool the heat exchanger.

Reheat and expansion:

After the water separation, the cold high-pressure air is reheated by the regenerator and finally enters the expansion turbine. The rapid expansion process causes the gas temperature to drop significantly and drives the turbine main shaft to rotate at high speed, thus realizing the circulation operation of the air conditioning component. In some large passenger aircraft, in order to increase the cooling capacity, a second-stage expansion turbine is also added to the air conditioning component.

Bypass control system:

In the actual aircraft air conditioning component, in order to control the output temperature of the air conditioner, some control pipes and valves, as well as supporting sensor systems, are also installed. The bypass valve and bypass pipe can directly introduce the higher temperature compressed air flowing through the primary heat exchanger into the expansion turbine, thereby regulating the temperature of the output airflow of the component, and can also prevent ice blockage caused by the condenser temperature being below the freezing point.

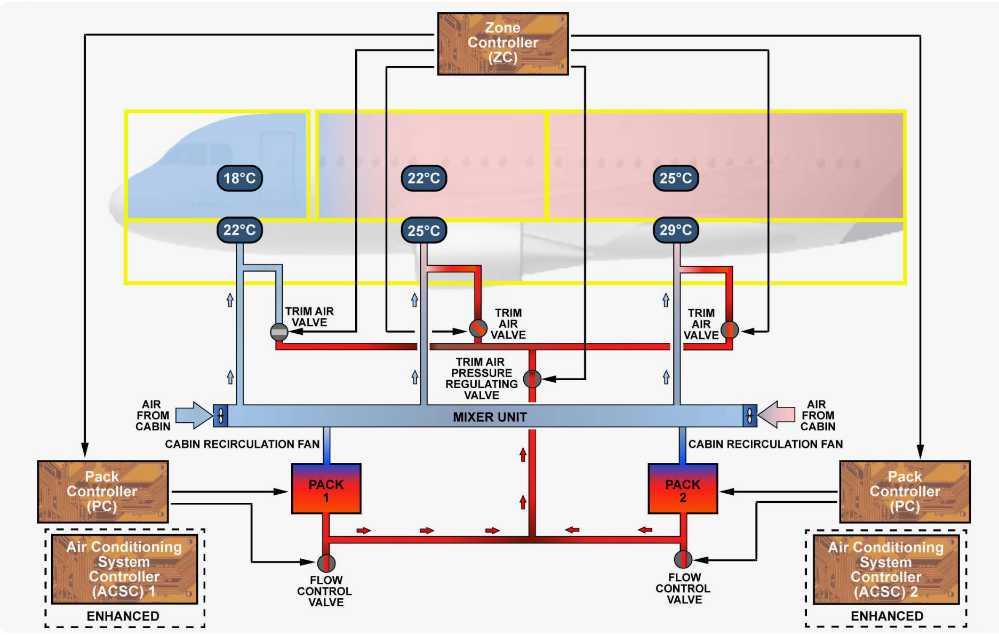

So far, we have obtained low-temperature and normal-pressure air conditioning cold air, but the temperature and air volume required for the cabin, cargo hold, cockpit and electronic equipment compartment are not the same. The cockpit requires a lower ambient temperature of 18℃, the temperatures of the front and rear cabin sections are set at 22℃ and 25℃ respectively, and the cargo hold also needs to control temperature and pressure to prevent damage to fresh goods. In order to provide pressurized air that meets the requirements to each area while minimizing energy waste, engineers set up an air mixing unit. In the air mixing unit, the air from the air conditioning component will serve as the main cold source and fresh air source, and some air from the cabin return air outlet will be sent here for recycling after being removed from pollutants such as bacteria, viruses and dust by the air filter to avoid waste. The temperature of the two air streams after mixing is relatively low. In order to adjust the air temperature, an appropriate amount of hot bleed air that has been reduced in pressure by the pressure relief valve can be introduced through the balancing air valve, so that high-quality air with temperature and pressure that meet the requirements can be delivered from each air outlet.

The air pressure in the cabin cannot be increased infinitely, and the air containing pollutants must be discharged in time, so it is also necessary to set an outflow valve for discharging excess air; in order to prevent the cabin from overpressure or underpressure affecting the safety of the fuselage structure, it is also necessary to set a safety valve, which automatically opens to adjust the pressure difference when the difference between the internal and external air pressure is too large. All operations related to cabin pressurization and temperature adjustment are usually automatically controlled by the air conditioning system controller, but if the pressurization switch in the cockpit is turned off or in manual mode, this automatic adjustment mechanism will fail. If the pilot forgets to turn on the automatic pressurization function before the aircraft reaches the cruising altitude, the cabin personnel will be deprived of oxygen and comatose, and eventually the aircraft will be destroyed and people will die. In 2003, the Greek Helios Airlines Flight 522 crash was a painful lesson caused by this.

In order to further reduce the energy consumption and environmental pollution generated by aircraft during stopovers at airports, more and more airports have installed ground air conditioning units. Its principle is similar to that of steam compression air conditioners used in buildings. After the outdoor air is adjusted to the self-standard temperature inside the equipment, the air flow is directly sent to the air mixing unit on the aircraft through the air duct. The ground air conditioning unit is generally installed directly next to the aircraft stand or hung under the boarding bridge, and connected to the aircraft with a yellow hose.

Be prepared for any eventuality-onboard emergency oxygen supply system

Under normal circumstances, the above environmental control system is sufficient to ensure that the cabin has a comfortable temperature and air pressure in various situations. However, if the cabin of the aircraft loses pressure at an altitude of 10,000 meters, the aircraft’s air conditioning system alone cannot provide enough oxygen for the people on board. Therefore, a set of devices that can provide emergency oxygen to the people on board has become a rigid need for safe flight. For passengers, the emergency oxygen supply system is actually not unfamiliar. In film and television works or safety instructions videos, the amount of oxygen released by the aircraft in an emergency is connected to it. The device has evolved from the oxygen cylinder + mask of the earliest aircraft, but the bulky oxygen cylinder is a huge burden in normal flight, which not only reduces the operating economy, but also requires additional maintenance. Therefore, chemical oxygen generators (also known as oxygen candles) came into being. They rely on oxygen generators such as lithium perchlorate or potassium chlorate to produce a large amount of oxygen by violent chemical reactions at high temperatures. For general commercial flights, the chemical oxygen generator’s working time of about 15 minutes is enough for the pilot to control the aircraft to descend from the cruising altitude to an altitude of about 3,000 meters, where the oxygen content of the air allows people to breathe independently without hypoxia. However, after the device is ignited, it can generate extremely high temperatures, and the oxygen produced can help combustion. If it accidentally catches fire and there are other flammable materials nearby, the consequences will be disastrous. The crash of Valujet Flight 592 in the United States was caused by a large number of chemical oxygen generators being mistakenly stacked in the cargo hold by the airline. These devices accidentally caught fire during the flight, producing deadly high temperatures and toxic gases.

For high-altitude routes or routes that fly over high plateaus for a long time during the cruising phase, the aircraft must be equipped with a longer-lasting emergency oxygen supply system to ensure safety, which generally relies on oxygen cylinders installed in the cargo hold. In addition, to ensure that pilots can breathe oxygen at any time, emergency oxygen masks that can provide oxygen for a long time and can be quickly worn with one hand are also required to be installed in the cockpit. In addition, there are usually small oxygen cylinders placed in the luggage rack on the plane for flight attendants to use in first aid or other emergencies. In the famous 3U8633 flight incident, the pilot relied on the cockpit oxygen mask to stay awake, control the plane to leave the mountain area, descend to a safe altitude and make a smooth emergency landing.

In just over a hundred years, airplanes have been flying higher and faster. With the continuous development of commercial aviation, people’s requirements for cabin comfort and system economy have been continuously improved. The corresponding onboard environmental control measures have also developed from passive heat-insulating leather goggles to cabin air conditioning systems that actively adjust cabin air parameters. Ground air conditioning, electric compressors and other facilities have been continuously promoted. In order to ensure the safety of personnel in special circumstances, engineers have developed various emergency oxygen supply systems. These sophisticated designs are gathered on modern passenger aircraft, helping the modern aviation transportation industry to fly towards a safer, more comfortable and more economical goal.