With the changes in the international situation, the possibility of a high-intensity ground war in the European region has begun to increase. In this case, it is very natural for the United States, Russia and Europe to innovate and reorganize their ground forces, and the planning and technical research and development of the next generation of tank gun firepower is the top priority.

Since the outbreak of the Ukrainian crisis, NATO has continuously increased military pressure around Russia. From the perspective of the United States, holding high-intensity exercises with Russia as an imaginary enemy can stimulate Russia to respond militarily, and in turn force European member states to increase their defense investment. From the perspective of some European member states, this is also conducive to focusing the collective defense on Europe, effectively enhancing the defense and deterrence capabilities against Russia, and thus alleviating their own fear of Russia. According to the laws of NATO’s military operations and the development trend in recent years, NATO’s military exercises against Russia in Eastern Europe will continue to be carried out and present a high intensity. NATO’s continued creation of tensions around Russia will lead to an escalation of confrontation between the two sides, have a series of impacts on the regional and even global security situation, and significantly increase the risk of accidental firing. NATO’s aggressive posture not only poses a serious challenge to Russia’s national security, but also further intensifies the military confrontation between the two sides and increases the possibility of military friction and conflict. During the "Poseidon 2021" and "Sea Shield 2021" exercises, the Russian army closely monitored NATO forces in the Black Sea region, and the fighter planes of both sides even had close contact. In response to NATO’s continued pressure, Russia and Belarus held three tactical exercises and one command exercise in March 2021, and held a large-scale strategic exercise "West-2021" against NATO with Belarus in September 2022, in order to send a stern and powerful military warning to NATO. Southeast Europe is more likely to be difficult to stabilize for a long time. Among the six coastal countries of the Black Sea, in addition to Russia, three are NATO members, and two NATO special partners, Ukraine and Georgia, are waiting to join the alliance. However, the Black Sea region involves Russia’s core geopolitical interests, and Russia will do its utmost to counter NATO. As the game between the two sides continues to escalate, the security situation in Southeast Europe has become increasingly worse, as evidenced by the nearly one-year-long Russian-Ukrainian conflict. Therefore, as a preparation for a high-intensity ground war, the United States, Europe and Russia have also made efforts on the issue of the next generation of tank gun firepower.

Basic technical environment supporting the next generation of main battle tank gun firepower

The United States, Europe and Russia have a basic technical environment for the development of the next generation of tank gun firepower, that is, the full popularization of tank automatic loaders. As the caliber of tank gun shells continues to increase and the weight of shells approaches the limit of manual loading, everyone believes that automatic loaders are the development trend. Chinese and Russian main battle tanks have used automatic loaders for a long time. Among Western tanks, France, Japan, and South Korea have all used automatic loaders, but they are different schools. Russia’s two configurations are both turntables, one is the single-push loader of T-80 and T-64 tanks, and the other is the two-push loader of T-72 and T-90. The former has a faster loading speed than the latter, but its reliability is not very good. In addition, Kharkov, which produces the T-80 series tanks, has been assigned to Ukraine. At present, Russia’s main loader is a two-push loader. Now the loaders of T-90M and T-72B3 have been modified to a certain extent and can fire the latest 3BM59 and 3BM60 armor-piercing shells in the 2A46 series. The T-14 "Armata" tank uses the 2A82 tank gun, and the shells are all new "vacuum" 1/2 armor-piercing shells, which cannot be used with the 2A46. The specific loader configuration is still unknown. The loader of the Western main battle tank is mainly the tail compartment loader, which is used by France, Japan, and South Korea. The technical source is the MBT-70 developed by the United States and Germany in the 1970s. It is equipped with a belt-type automatic loader developed by the United States in the turret tail compartment. The belt compartment is driven by a chain. When the magazine moves to the push line, the magazine sleeve extends forward and the chain pusher completes the push. The advantages of this type of automatic loader are simple structure, fast firing rate, changeable ammunition type, and reloading inside or outside the vehicle. The disadvantages are limited ammunition supply and large turret space requirements. As for the US M1 series, Germany’s Leopard 2 series, and the UK’s Challenger 2, they are all manually loaded. However, these manually loaded Western main battle tanks have the technical possibility of being modified with automatic loaders. Take the US automatic loader modification plan for the M1 series as an example. This is an automatic loader with a double rotating magazine structure in the tail compartment. Each rotating magazine is equipped with 18 rounds of ammunition. The warhead is backward, and the rotating loader takes the bullet and rotates 180 degrees before pushing it into the gun barrel. The Americans hope to install an automatic loader for the M1 series in order to increase the firing rate of the tank, especially in the case of long-term combat and high-speed driving of the tank on rugged ground. At the same time, since the crew members are still 4, the loader becomes a drone operator, expanding the boundaries of situational awareness, but more importantly, it lays the foundation for the future replacement of larger caliber artillery-tank guns with a caliber of more than 120 mm cannot be loaded manually.

The new generation of tank gun systems in the United States

During the Cold War, in order to fight against the steel torrent of the Warsaw Pact, the United States spared no effort in the development of tanks. From the "Patton" series to the M1 series, the performance of the US main battle tanks has been continuously improved. However, with the end of the Cold War, the US Army lost its imaginary enemy, and what followed was the thinking and confusion about future development-whether to completely abandon heavy equipment and take the fast and light response route (FCS), or to continue to develop new main battle tanks, the US military also argued endlessly. Against this background, the new generation of US main battle tanks has been nowhere to be seen. Although the United States has not introduced any new tanks in the 30 years since the end of the Cold War, this does not mean that they are standing still in terms of technology. Behind the continuous improvement of the M1 series main battle tanks, relevant US agencies have conducted extensive research on new technologies for future tanks, such as unmanned turrets, 140mm advanced tank guns, active protection systems, new tracks, etc. In order to verify whether these new technologies can be applied to actual combat, the US Army Tank Motor Vehicle Research and Development Engineering Center also manufactured a main battle tank test prototype called M1 BlockIIICATTB (hereinafter referred to as M1CATTB) in the 1990s. Today, we can still see some shadows of the future new generation of main battle tanks of the US military from this vehicle. M1CATTB adopts a modular design concept, integrating many new technologies such as advanced tank guns, automatic loaders, standard digital information structures, new integrated diesel engine propulsion systems, and multi-sensor target acquisition systems. To put it in an exaggerated way, it is a science fiction product that piles up all the high-tech of the US Army.

Among the above new technologies, the most noteworthy one is probably the XM291 140mm advanced tank gun. The electrothermal chemical gun was once considered a substitute for the traditional chemical energy tank gun. In the early 1990s, General Motors and Food Machinery Company of the United States converted the 120mm caliber M256 tank gun into an electrothermal chemical gun for testing. In 1991, the US Army signed a research contract for the "Electric Enhancement Factor Improvement Project" with Food Machinery Company to fund the company to conduct electrothermal chemical technology research. Unfortunately, these experiments were not successful. The electrothermal chemical gun uses two main plasma excitation methods: flash large area generator and triple coaxial plasma igniter. The former is more advanced in technology and has higher requirements for the density and expansion characteristics of the propellant. The flash large area generator consists of several parallel strings to provide a wider range of plasma or ultraviolet radiation, and uses the decomposition and gasification of diamond to obtain the required plasma gas. The triple coaxial plasma igniter is composed of a fully insulated conductor, covered by 4 aluminum foils, all of which are insulated in a small hole with a diameter of about 1.6 cm. The current through the conductor directly decomposes the plasma gas, and then the gas escapes through the insulating conduit and ignites the nearby propellant. This method is no longer considered a reliable way to ignite the propellant because it may damage the heat sink, and the energy conduction efficiency is also unstable and generally low. It is precisely because of this that the technical verification of the XM291 140mm advanced tank gun is still realistic today compared to the immature electrothermal chemical gun.

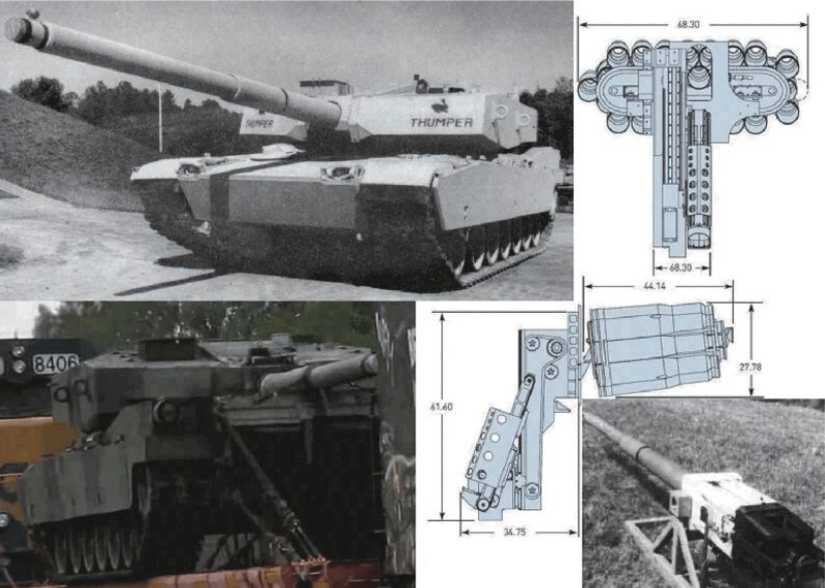

As a large-caliber tank gun, the power of the XM291 is huge. According to data, its kinetic energy when fired is twice that of the US military’s current M256 120mm smoothbore gun, which can effectively deter current and future main battle tanks. Moreover, with the cooperation of the automatic loader, the theoretical rate of fire of the gun can reach 8~12 rounds/min, which is faster than the rate of fire of the 120 tank gun in service. Obviously, the automatic loader system plays an important role in whether the 140mm advanced tank gun like XM291 can be put on the new generation of main battle tank platform of the US military. In fact, based on the technical verification of M1CATTB, the US military has envisioned two different automatic loader schemes for 140mm tank guns. One of the schemes is that the automatic loader consists of a horizontally placed ammunition compartment with a capacity of 40 rounds, an ammunition converter, a turntable with a capacity of 4 rounds, and an ammunition feeding device. Another design consists of a vertically placed ammunition compartment with a capacity of 40 rounds, a turntable with a capacity of 2 rounds, an ammunition converter lifting mechanism, a conveying device, etc. It is worth noting that the modernity of the XM291140mm tank gun is not given by the gun itself to a large extent, but depends on the ammunition. In recent years, the U.S. military has made a series of low-key progressive achievements in the field of high-pressure tank gun ammunition. Taking the M829A4 armor-piercing projectile for the M256 120mm tank gun as an example, it is generally believed that the M829A4 uses a brand-new multi-layer propellant. Multi-layer propellant is to wrap propellants with different burning rates together, with the outer layer burning slowly and the inner layer burning quickly. Under the premise of not increasing the maximum chamber pressure of the gun, the plateau period of the chamber pressure curve is increased as much as possible, so as to achieve the purpose of increasing the initial velocity of the projectile. It is reported that the United States has also introduced nano-energetic materials into multi-layer propellants to increase the power of the propellants.

These two methods will increase the initial velocity of the M829A4 core to a certain extent and increase the penetration depth. In addition to armor-piercing projectiles, the United States has also made considerable progress in multi-purpose ammunition for large-caliber high-pressure tank guns. For example, starting from the M1A2C, the M256 120mm tank guns of the U.S. military’s active Abrams fleet are fully equipped with ammunition data links (ADL). ADL is a data link installed on the gun port that can transmit signals to the shells. For example, the AMP shell, which can replace four types of shells at once, including armor-piercing grenades (HEAT), multi-purpose grenades (MPAT), obstacle-breaking shells (HE-OR) and anti-personnel shotgun shells, will set the air-burst time through ADL according to the distance of the target when setting the air-burst mode. At the same time, although the M829A4 is a kinetic armor-piercing shell, an interface connected to ADL is also added to the shell base. The purpose is to maintain a uniform speed at any temperature and to make the penetration ability unaffected by environmental factors, making the performance more accurate and stable. The technical achievements made in these ammunitions can obviously feed back to the 140mm tank guns that have been born in advance, making the firepower of the new generation of US main battle tanks mature and highly available from the beginning.

Russia’s new generation of tank gun systems

Similar to the situation in the United States, Russia has also begun to lay out relevant technical research on the new generation of tank gun systems as early as the end of the Cold War. In the 1980s, at the height of the Cold War, the United States, the Soviet Union and other countries were all working hard to develop advanced weapons in an attempt to overwhelm their opponents in terms of military strength. As many NATO countries began to develop new main battle tanks, the Soviet Union naturally did not want to lag behind in its traditional strengths. In order to effectively deal with the frontal armor of future main battle tanks and to crush the 140mm tank guns of the West in terms of caliber, the Soviet Union put the development of main battle tanks with a main gun caliber of 152mm on the agenda.

In 1982, the Kharkov Machinery Manufacturing Plant began to develop a new generation of main battle tanks code-named Project 490A. Unlike previous Soviet main battle tanks, this tank adopts an unmanned turret design, equipped with a powerful 152mm main gun and a new automatic loader, with a theoretical rate of fire of up to 14 rounds per minute, far superior to the main battle tanks currently in service. In addition to its powerful firepower, Project 490A also has very strong information acquisition and processing capabilities. The various sensors throughout the vehicle body can quickly capture target images, and at the same time, they are integrated into clear images through computers and provided to the crew members. According to the concept, the fire control system of Project 490A also has target positioning and tracking functions, and can maintain excellent working conditions in complex environments. However, the research and development agency believes that Project 477/477A has been put on the agenda.

In 1985, in order to install a more powerful 2A83 152mm smoothbore gun on the tank, the Kharkov Mechanical Manufacturing Plant proposed Project 477/477A with a completely new layout and weapon system. The tank is equipped with multi-layer composite armor, the thickness of the front armor of the hull is said to be more than 1 meter, and a large number of composite armor modules are also installed on the side. From the front, the project is quite similar to the "Armata" main battle tank. In addition, Project 477/477A is equipped with a satellite navigation system and an enemy identification system, and remote control driving and remote control firing technology have also been tested. The further development of Project 4771477A is called Project 299, which innovatively adopts a two-person layout, that is, one person is responsible for operating the tank and the other is responsible for hitting the target. This shows that the tank is highly automated. Project 299 also has a huge vehicle family plan. Based on the universal chassis, the Soviet military industry plans to develop a series of variant vehicles: including heavy infantry fighting vehicles, mechanized mine sweepers and vertical launchers. However, as the basis of the entire vehicle family, the core of Project 299 is still the turret equipped with the 2A83 152mm gun. In addition to the newly designed Projects 490, 477, and 299, there were some transitional projects that also used the 2A83 152mm smoothbore gun before the collapse of the Soviet Union. For example, in September 1990, the Soviet Union developed Project 292 equipped with the 2A83 152mm gun based on the T-80 chassis. This tank uses a brand-new large turret and is equipped with a newly designed automatic loader and composite armor. Another transitional project of 152mm tank guns that was manufactured before the collapse of the Soviet Union was Project 195. The project has been up and down several times after the collapse of the Soviet Union, but it was still undergoing intensive testing on the test site until around 2000. Obviously, no matter how the Soviet Union/Russia has a wavering plan on the next generation of main battle tank platforms, the new generation of 152mm caliber tank guns are the core.

It is generally believed that the 2A83 152mm smoothbore gun has a barrel length of 56.5 times the caliber and adopts a self-tightening barrel process. The muzzle kinetic energy reaches 25 megajoules. The inside of the barrel is also chrome-plated, which reduces internal ablation and increases the service life of the gun. The main technology was basically mature before the disintegration of the Soviet Union. Moreover, supported by the development achievements of the new generation of Russian high-pressure tank gun ammunition technology, the installation of the 2A83 152mm smoothbore gun is more realistic. The 125mm tank gun ammunition in the Soviet era has long lagged behind the West. For example, the 3VBM17 armor-piercing projectile equipped with the T-80B is the first tungsten alloy armor-piercing projectile developed by the Soviet Union in the 1980s. Its core is the famous 3BM42, which can penetrate 450mm homogeneous steel armor at 2000 meters. However, due to the inadequate sintering technology, in order to achieve a higher bullet-diameter ratio, the bizarre "two-section tungsten alloy rod + steel sleeve connection" design was adopted. At large angles, the penetration will drop significantly. Therefore, the actual performance did not surpass the Western products of the same period. The 3VBM20 is the last armor-piercing projectile developed by the Soviet Union. It was launched in 1991 and uses a 3BM46 depleted uranium alloy core. The penetration depth at 2000 meters reaches 600 mm, which is basically equivalent to the early M829. This ammunition is also the best performing mass-produced armor-piercing projectile adopted by Russia for a long time, but it is only between the basic M829 and M829A1. With the disintegration of the Soviet Union, Russia’s economy and finance fell into a cold winter. Coupled with the large number of 3BM42 and older armor-piercing bullet stocks left over from the Soviet period, Russia also lost the motivation to equip new ammunition and entered a 10-year stagnation period. During these 10 years, only one 3BM42M was successfully developed. Although it is the only one left, it is still reliable. Russia used improved liquid phase sintering technology on this armor-piercing projectile, so that the 3BM42M has a 570 mm long integral tungsten alloy rod, completely bidding farewell to the era of steel-sheathed tungsten cores. Since then, Russia has made greater achievements in high-pressure long-rod tail-stabilized armor-piercing projectiles, such as the 3VBM22 and 3VBM23 developed in 2002. The two have the same projectile body, but one uses a 3BM59 depleted uranium alloy projectile body and the other uses a 3BM60 tungsten alloy projectile body. The weight of the flight bodies of both models has been greatly increased compared to the previous models, reaching 8.8 kg and 8.1 kg, and the export kinetic energy has reached 12 megajoules. The armor-piercing ability is very impressive, reaching 830 mm and 740 mm respectively. Later in 2005, Russia developed two newer generations of 125 mm "vacuum" 1/2 long-rod tail-stabilized armor-piercing projectiles. The length of these two ammunitions is frighteningly high. The length of the part with the flying body reaches more than 900 mm, which is almost equivalent to an American M829A3. However, the M829A3 is only a fixed-charge ammunition, and the propellant and the flying body are installed in a cartridge, while these two are still separate charges, and there is also a cartridge. Therefore, it is speculated that the penetration depth of this ammunition should be far beyond the current ammunition, and its technical achievements can also be used for the new generation of 152mm smoothbore guns with a larger caliber, paving the way for the second phase of the firepower innovation of the "Armata" main battle tank.

Europe’s new generation tank gun system

As a key participant in the geopolitical confrontation between the United States and Russia, Europe is highly likely to be involved in high-intensity ground wars, so it is very willing to innovate and develop a new generation of tank gun firepower. For example, the prototype of the French "Leclerc" tank equipped with a 140mm tank gun has been exposed, and its huge gun barrel is very conspicuous. At the London International Armored Vehicle Exhibition in early 2020, the French Nexter company exhibited a new version of the "Leclerc" main battle tank equipped with a 140mm "giant gun". From the caliber point of view, it is obviously larger than the tank guns of the current tanks in various countries, and the length is also longer than the German RH120 tank gun. Compared with the traditional "Leclerc" main battle tank, this test vehicle uses a rare hard stripe camouflage, and a new 140mm smoothbore gun is installed on the turret.

There are some differences in appearance: First, the standard "Leclerc" main battle tank is equipped with a GIAT CN-120-26 120mm 52-caliber smoothbore gun. Compared with other smoothbore guns of the same caliber, in order to pursue internal ballistic performance, there is no gun barrel smoke extraction device, but compressed air is used in the fighting room to blow away the smoke and gunpowder in the gun barrel after firing. On the new 140mm smoothbore gun, a small-sized gun barrel smoke extractor is installed at the root of the gun. As you can see from the photo, there is a thickened part in the middle of the rear of the barrel. Its function is to extract the gunpowder gas remaining in the barrel after the shell is fired, thereby reducing the concentration of carbon monoxide in the fighting chamber to protect the crew from polluted air. In addition, the muzzle brake is a means of reducing the recoil of the gun. It first appeared in the mid-19th century and is still widely used in towed artillery and light armored vehicle artillery. It can even reduce the recoil by more than 50% when combined with the barrel recoil device. The muzzle brake can be divided into "impact type", "reaction type" and "impact-reaction type" in terms of structure. Compared with the standard "Leclerc" main battle tank without any muzzle brake installed, the 140mm straight-bore gun on this new "Leclerc" main battle tank uses a double-chamber impact brake. Interestingly, as modern tanks are getting heavier, the recoil of the gun is no longer a problem for heavy main battle tanks, so modern main battle tanks rarely use muzzle brakes. This device is generally used on light vehicles. The use of a muzzle brake on the "Leclerc" main battle tank with a combat weight of 53 tons also shows the huge recoil of the 140mm gun, and large recoil also represents huge power.

The "Leclerc" main battle tank is one of the few third-generation main battle tanks in Western countries equipped with an automatic loader. The entire vehicle has only 3 people. The use of the automatic loading system not only reduces the manpower demand, but also makes the tank more compact and greatly increases the rate of fire, making the rate of fire of the 120mm gun reach 12~15 rounds per minute. However, due to the replacement of the new 140mm gun, the ammunition size is larger and longer, and the original automatic loader must be redesigned and adjusted. Since the automatic loader is an internal device of the tank, it cannot be seen from the outside, but from the appearance of the rear of the new "Leclerc" tank turret, it is indeed larger and wider, so there is reason to believe that the French have developed a new type of 140mm automatic loader for loading ammunition in the rear compartment. In addition, the French also exhibited new 140mm ammunition.

Some comments said that this huge gun that appeared on the "Leclerc" main battle tank is actually part of the "Future Ground Combat System" MGCS, which has been rumored to be jointly developed by France and Germany. This project is to make technical preparations for the development of the fourth-generation tank. According to Nexter’s public introduction, this 140mm smoothbore gun installed on the Leclerc main battle tank has been tested for about 200 times, proving that its armor-piercing ability is 170% of the 55-caliber RH120 smoothbore gun. If this data is true, it means that the 140mm tank gun will become the most powerful tank gun in the world, far exceeding the 105, 120, and 125mm caliber traditional tank guns currently in common use. In fact, as early as the 1980s before the end of the Cold War, European countries had already begun to focus on a new generation of tank guns with a caliber of more than 120mm. For example, Germany and Switzerland jointly developed a 140mm smoothbore gun and tested it on a "Leopard" 2A4 main battle tank.

France also tested a similar 140mm smoothbore gun in 1996. However, European countries once had doubts about the larger caliber tank guns of 120 mm, believing that it would have various adverse effects on the overall design of main battle tanks. For example, if the gun barrel is too heavy, the tank turret will be heavy in front and light in the back, especially the barrel length of this type of super-large caliber high-pressure smoothbore gun is also super long, making the torque effect more obvious. In order to maintain balance, equipment or counterweights must be added to the rear of the tank turret. In this way, the weight of the entire tank turret will increase exponentially, which not only directly increases the weight of the entire tank, but also makes the electromechanical hydraulic servo mechanism that drives the turret to rotate bear a huge load. Moreover, the fire control system of modern main battle tanks also has very high requirements for the rotation speed of the turret. To meet the requirements, the driving power of the electromechanical hydraulic servo mechanism must be further strengthened. In the end, like a domino, starting from the super-large caliber high-pressure smoothbore gun barrel is too long and overweight, the entire tank design will have to be completely overturned and started again, until the weight and volume of the entire tank increase to an uncontrollable level. It is for this reason that Russia did not use the powerful 2A83 152mm smoothbore gun on the latest version of the T-14 "Armata" main battle tank, but instead used the improved 2A82-1M 125mm smoothbore gun. For similar reasons, European countries such as France and Germany gave up the idea of modifying 140mm tank guns in the 1980s and 1990s. However, due to more advanced technology and financial support, Europe has gradually moved away from its previous doubts about larger caliber tank guns in recent years and has begun to work on a practical new generation of tank gun systems.

As mentioned above, France is not the first country to develop a 140mm smoothbore gun. In fact, another French company also developed a 140mm smoothbore gun in 1996, but it soon came to nothing. After 16 years, France tested the 140mm smoothbore gun again, but this time it was another company. At the same time, it should be noted that France’s 140mm smoothbore gun is just a bidding plan for the "Future Ground Combat System" MGCS firepower system jointly developed by France and Germany. In fact, in terms of power, adaptability and other aspects, the 130mm smoothbore gun of the German Rheinmetall Defense Company is much better than the 2A83 152mm smoothbore gun, and it is also likely to have superiority over the French 140mm smoothbore gun. The German Rheinmetall Defense Company calls this 130mm smoothbore gun NG130, where NG is the abbreviation of "Next Generation" in English. From this name, it can also be seen that the German Rheinmetall Defense Company hopes that the 130mm smoothbore gun can become the standard main gun of the next generation of main battle tanks in Europe and the United States, just like the classic 120mm smoothbore gun. According to the German Rheinmetall Defense Company, the NG130 130mm smoothbore gun has a 50% performance improvement over the 55-caliber 120mm smoothbore gun.

According to the previous comparison of the firepower performance of the new and old generations of main battle tanks, this improvement has reached the requirements of the generation gap. Moreover, if the NG130 130mm smoothbore gun really achieves this goal, it means that when it launches the latest fin-stabilized armor-piercing projectile, the maximum armor penetration depth at a distance of 2000 meters will reach more than 1200mm! The NG130 130mm smoothbore gun uses a 15-liter super-large chamber, which is half the size of the 55-caliber 120mm smoothbore gun, and the design chamber pressure is as high as 880 MPa. More importantly, in terms of adaptability, the NG130 130mm smoothbore gun is designed to take into account the use requirements of the third-generation improved main battle tank as much as possible. To this end, the barrel length of the gun is controlled at 51 times the caliber, which is only 50 mm longer than the barrel of the 55-caliber 120mm smoothbore gun. In fact, in order to better complete the development of the NG130 130mm smoothbore gun, Germany’s Rheinmetall Defense and the British BAE Systems have joined forces to establish a new joint venture called Rheinmetall-BAE Land Systems (RBSL) to be responsible for this work. Today, the development of the NG130 130mm smoothbore gun has advanced to the actual vehicle testing stage. The KF51 "Black Panther" tank unveiled at the 2022 Sartori Defense Exhibition has been equipped with NG130, thus adding a key weight to the bidding for the "Future Ground Combat System" MGCS firepower system.

Additional remarks

In the face of a world situation where a brutal and high-intensity ground war is likely to break out, not only has Russia, which has been threatened by NATO, chosen to rearm its armored forces, but NATO itself is also in a state of anxiety, and rearming heavy armored forces has become one of the few options. In this regard, the attitudes of the United States, Russia, and Europe towards the upgrade of the firepower of the next generation of tank guns clearly show this point. The once interrupted wave of large-caliber tank gun replacement has actually been restarted. Interestingly, the ongoing Russia-Ukraine conflict has also provided valuable battlefield experience for the development of a new generation of large-caliber tank guns. On the one hand, with the improvement of the level of informatization, relying on advanced reconnaissance platforms such as drones, the long-range strike capability of artillery has shown an exponential improvement. As a result, Russia and Ukraine, two countries that "lack everything but tanks", have not staged a "steel torrent collision" so far, and there has not even been a battalion-level tank battle. In addition to tanks that were abandoned due to malfunctions and siltation, more than 90% of the losses of tanks on both sides came from the bombardment of howitzers and long-range rocket launchers.

On the other hand, when the battle enters the ground occupation and urban assault, tanks are still indispensable assault and direct fire platforms. Especially when breaking through the preset solid defense areas, the role of tanks is still irreplaceable. In the face of highly anticipated single-soldier portable anti-tank weapons such as NLAW and FGM-148 "Javelin", the main battle tanks have shown amazing anti-strike capabilities, and the losses that can be confirmed for the mountain so far are less than double digits. However, in a highly informationized battlefield, the threats faced by main battle tanks have increased significantly compared to the past, and the situation of "strong attack and weak defense" since the end of the Cold War is quietly reversing. The main difficulty faced by main battle tanks on the battlefield is that the traditional weapon system configuration is not enough to deal with all potential threats. Therefore, for the next generation of tank gun firepower, a broader mission capability requirement is proposed than the focus on anti-armor during the Cold War. For example, tapping the potential of the next generation of tank guns, so that the next generation of tank guns have a certain air defense capability to fight against enemy armed helicopters and low-altitude reconnaissance and strike integrated drones. In this regard, programmable fuze ammunition such as AMP that matches the new generation of large-caliber tank guns is a better choice than small-caliber artillery remote-controlled weapons. With the current level of the main battle tank’s fire control system, there is still a good detection rate for conventional low-altitude and slow-flying targets such as armed helicopters. Due to the high initial velocity of tank guns, when both sides take action within visual range, most of the time anti-tank missiles are still a beat slower. At the same time, because on the Russian-Ukrainian battlefield, the role of tanks is more reflected in mobile armored direct-aiming artillery, most of the battlefield targets to be dealt with are civil engineering and personnel. Therefore, the possibility of a return of large-caliber rifled tank guns with better low-cost multi-purpose performance at long distances cannot be ruled out. In addition, after the leap in the level of informatization, the coordination of the entire system will crush a single superior weapon. For example, the concept of NIFC-CA "Navy Integrated Fire Control-Air Defense System" based on the concept of network-centric warfare, if extended to the army equipment system represented by tanks, will greatly change the battlefield situation, and this change is currently happening, which means that after being connected through a highly confidential data link battlefield network, it is possible to use the next generation of large-caliber tank guns as a low-cost beyond-visual-range weapon in the "A shoots B guide" mode.

Conclusion

From the current development of the new generation of main battle tanks in various countries around the world, the technical standards of the fourth-generation main battle tanks have begun to emerge, such as unmanned turrets, integrated crew compartments, comprehensive active and passive defense systems, high network informatization capabilities, and vehicle-mounted drones, but in any case, the innovation and upgrade of tank gun firepower will be the most core part of it.