This article is a tank technology article written by a Chinese tank researcher. It describes in detail the development ideas of the next generation of protection technology for Chinese tanks. The technical routes mentioned in the article can help us understand the development level of Chinese technology. The full text is reproduced.

Since the birth of the tank, it has irreplaceable tactical value and significance because it integrates firepower, mobility and protection. It has become a key force for rapid strikes or mobile defense. However, it is undeniable that with the rapid progress of individual anti-tank weapons and the development of air-to-ground strike forces centered on armed helicopters, ground attack aircraft and drones, the battlefield survivability of main battle tanks has been greatly challenged. Therefore, improving the protection capabilities of main battle tanks has become a top priority. However, blindly increasing armor will seriously deteriorate the mobility and off-road capabilities of the tank, and ultimately make the tank a flashy "toy". Among them, the German "King Tiger" tank at the end of World War II is the best example. In addition to using armor to resist enemy attacks, tanks still have many ways to avoid being destroyed, such as launching smoke bombs. Therefore, it is no longer appropriate to continue to use protection capability as one of the three major indicators for judging the capabilities of main battle tanks. Instead, it should be replaced by "survivability".

The survivability of a tank should include the following four aspects: 1. The tank is not easy to be discovered; 2. The tank is not easy to be hit after being discovered; 3. The tank is not easy to be penetrated after being hit: 4. The tank is not easy to cause casualties after being penetrated. Among them, the first point is mainly achieved through camouflage and concealment, the second point is achieved through interference and active protection, the third point is mainly achieved through more powerful and advanced armor, and the fourth point is mainly achieved through concentrated crew deployment and ammunition compartments.

At the same time, the technology used by the next generation of main battle tanks should be mature, low-cost and mass-produced technology, while new concept technologies such as electromagnetic armor will be difficult to apply.

This article will replace protection technology with tank survivability to discuss the main characteristics of the technology used by the next generation of main battle tanks to improve survivability.

Camouflage and concealment

No matter how the war changes and how military technology develops, how to camouflage and conceal one’s own warheads to ensure that they will not be discovered by the enemy is always a topic that the front-line troops and the designers in the rear cannot avoid. As for the current use of armaments, the camouflage of armored vehicles and even various weapons and equipment is carried out by dividing the design and use into two modules, and the effect of camouflage is likely to be affected by objective factors. Therefore, relevant camouflage technology should be incorporated into the development of the weapons and equipment of the fourth-generation main battle tanks, so that they have better camouflage capabilities. Integrating camouflage technology with equipment will greatly simplify the camouflage and combat readiness processes, improve production efficiency and combat capabilities in wartime.

In the early 21st century, in addition to traditional camouflage, adaptive camouflage technology is also developing rapidly. Due to the mobility of the target itself and the influence of environmental changes, the optical infrared and other characteristics in the target background are constantly changing. Therefore, in order to ensure the concealment capability of the target, adaptive camouflage technology has been fully developed. However, the rapid development of adaptive camouflage technology does not mean that traditional static camouflage should be abandoned. For the design of the next generation of main battle tanks, the application of adaptive camouflage technology should be one of its main goals, and it should also be prepared to ensure that it can also have static camouflage capabilities.

In the early days, the army generally used single-color camouflage to hide combatants and equipment. However, this single-color camouflage played a very limited role in complex battlefield environments. Therefore, visual deformation camouflage and digital camouflage came into being with the development of the times and technology.

Visual deformation camouflage refers to a multi-color camouflage composed of several large spots of irregular shapes. This multi-color camouflage must conform to the main color of the target activity area background. The number of colors is related to the background and season, generally 2 to 5, and ultimately the outline of the active body is distorted to varying degrees on various backgrounds in the predetermined activity area. For the design of visual deformation camouflage, the background spot color, spot size and other data of the combat area and season should be fully considered. At the same time, an asymmetric design should be adopted, and dark spots should be configured for protruding corners and bright spots should be configured for recessed corners to ensure that the original outline of the active body is fully distorted. When designing visual deformation camouflage, in addition to the background environment, the size and shape of the tank itself also need to be considered.

According to the experimental results of the US military, under the same background and the same distance, the recognition probability of a tank without deformed camouflage and a tank with deformed camouflage is 96% and 54% respectively when observed with active infrared night vision goggles. Not only that, deformed camouflage can also reduce the hit rate of direct firearms by about 1/3. Therefore, when designing the fourth-generation main battle tank, the design of camouflage can be taken into consideration to a certain extent.

Digital camouflage, as a new type of camouflage, is a technology that expresses the background image in pixels and reproduces and recreates it on the surface of the equipment. It overcomes the shortcomings of traditional camouflage, including visual deformed camouflage, which is affected by distance, and realizes that the effector has a good camouflage effect at any distance, while being able to fight against aviation optical reconnaissance. However, due to the contradiction between refined painting and mass production, the use of digital camouflage is limited. For the next generation of main battle tanks, it is feasible to use digital camouflage before they are put into large-scale mass service to ensure that a small number of fourth-generation main battle tanks can have stronger combat effectiveness.

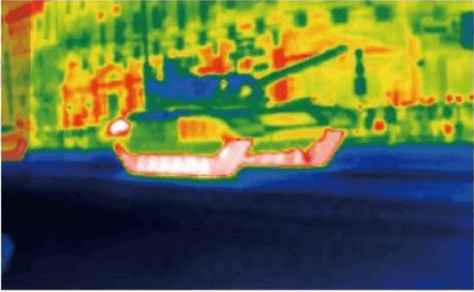

Although visual deformation camouflage and digital camouflage can effectively counter optical reconnaissance, the rapid development and widespread application of infrared reconnaissance technology and thermal imaging technology have made it increasingly difficult for tanks and other equipment to maintain good camouflage effects under these advanced reconnaissance methods. Therefore, in order to achieve the survival index of the next generation of main battle tanks "difficult to be discovered" mentioned above, it is necessary to adopt camouflage measures that can effectively counter infrared reconnaissance.

If camouflage for infrared reconnaissance is to be achieved on the basis of static camouflage, low-emissivity coatings are generally used to suppress infrared radiation from high-temperature metal parts such as engines and gun barrels, and the position of engine exhaust ports is reasonably arranged.

For low-emissivity coatings, foreign countries have used inorganic phosphate-filled aluminum powder coatings and alkyd resin-filled aluminum powder coatings, but because metal materials are mixed in the coatings, they have strong reflection effects in the radar band. By adding a small amount of metallic pigments to polymers and coloring pigments with high infrared transparency, a thermal stealth coating of any color with excellent visible light camouflage performance can be formed. Therefore, the coating made in this way has better performance. In view of the infrared radiation of high-temperature metal parts such as engines and gun barrels, the use of insulating materials to cover the high-temperature parts of the main battle tank can further reduce the thermal radiation characteristics of the main battle tank. For the engine exhaust port with obvious thermal radiation characteristics, its position can be moved and placed at the rear of the main battle tank body. If this type of layout is difficult to achieve, an exhaust gas cooling device can be installed for the exhaust port to cool the exhaust gas before discharging it.

In order to solve the problem that static camouflage cannot adapt to the ever-changing background environment, military technicians from various countries have proposed the advanced technology of adaptive camouflage. Adaptive camouflage should enable the target to blend with the natural background around it all day, all process and all time. In addition to visible light band, it should also be able to achieve camouflage with the surrounding environment in the infrared band.

The adaptive camouflage of main battle tanks in the visible light band can be achieved through thermal, electrochromic technology and "scene" technology. Thermal and electrochromic technologies change the color pattern of the coating through thermal or electrical control, or change the temperature and thermal radiation characteristics to adapt to the environment. "Scene" technology uses digital photography projection and display technology to project the environmental image around the object to the foreground of the object.

For the design of the next generation of main battle tanks, thermal and electrochromic technologies have greater technical feasibility than "scene" technology. First of all, on the modern battlefield, the use of optical reconnaissance and infrared reconnaissance technology has become more and more common, and even scenes of single soldiers holding thermal imagers have appeared. "Scene" technology can only achieve excellent results in the visible light band. Camouflage and concealment have poor concealment performance in the infrared band. In contrast, thermochromic and electrochromic technologies have infrared stealth capabilities to a certain extent. Second, the combat conditions of main battle tanks are harsh, and the projection and display equipment placed outside the vehicle body in the "scene" technology will be difficult to ensure its reliability. Therefore, the next generation of main battle tanks is very likely to use thermoelectric or any other signal-based color-changing technology as its camouflage technology.

The purpose of infrared adaptive camouflage is to actively adjust the surface temperature of the main battle tank to adapt to the infrared characteristics of the environment. Compared with the thermochromic and electrochromic technologies mentioned above, this technology does not change much. It is not color, but thermal radiation characteristics. In addition, phase change materials can be added to the paint to enhance the characteristics of adapting to the infrared characteristics of the environment.

Thermal and electrochromic technologies can achieve the requirements of blending with background thermal radiation through heat shielding plates and electric heating plates. The heat shielding plate is a three-dimensional grid material. It strengthens the heat exchange with the surrounding air to achieve the requirement of dissipating the heat of the vehicle body. However, in environments with higher temperatures such as Gobi, the heat emitted by the heat shielding plate is not enough to reach the ambient temperature by default. At this time, it is necessary to heat it with an electric heating plate to increase the temperature. The two work together to reasonably adjust the working power of the electric heating plate to achieve integration with the environment The fusion of ambient temperature.

In addition to using variable technologies such as electric heating plates to adjust the temperature of the tank surface, large phase change materials can also be used to absorb a large amount of heat to lower the temperature when the tank surface temperature reaches a certain temperature, or release a large amount of heat to increase the temperature. Specifically, phase change microcapsules containing phase change materials can be made and added to visible light camouflage paint. Considering that different parts of the main battle tank have different heat dissipation conditions, the type or content of phase change microcapsules in the paint should be appropriately adjusted to achieve a good camouflage effect, or even make the vehicle present a messy thermal radiation image to interfere with the enemy’s identification.

The previous article proposed a variety of camouflage technologies and briefly analyzed the characteristics and implementation methods of these technologies. The technology to be applied to the next generation of main battle tanks should be based on phase change materials, supplemented by adaptive camouflage technology in phase-changing technology, and apply digital camouflage coating

In order to cope with the increasingly complex battlefield environment and meet the requirements of strong concealment of the next generation of main battle tanks, the use of adaptive coating is the general trend. Phase-changing technology, whether it is color-changing technology or temperature-changing technology, has to place some relatively fragile components on the outside, and its reliability will be inferior to the adaptive camouflage technology that only needs to add phase-changing microcapsules to the coating. Although the scope of application of phase-changing technology is wider and can achieve multi-band camouflage of visible light and infrared, this article initially proposed that the technology used in the next generation of main battle tanks should first be mature and reliable. Therefore, the adaptive camouflage technology of the next generation of main battle tanks should be infrared camouflage technology with phase change materials as the core, but the ability to install and upgrade to variable technology must still be retained to ensure that the fourth generation of main battle tanks can be upgraded to apply variable technology when the time is right. It is precisely because phase change materials do not have the camouflage ability of the visible light band and have almost no effect on the form of coating. Therefore, based on the perspective of advancement and camouflage ability, in order to better make up for the above shortcomings, the next generation of main battle tanks are very likely to apply additional digital camouflage, which has the best camouflage effect in static optical camouflage.

Anti-hit technology

In order to obtain greater survivability, after being discovered by the enemy, the main battle tanks have a higher priority of evasion and interception than resisting enemy firepower strikes. Due to the limitations of factors such as the size and weight of the main battle tank, its sides, rear and top cannot be equipped with heavy armor. In view of this, foreign countries mainly use active protection technology to protect these weak positions. For example, Israel’s "Trophy" and Ukraine’s "Zaslon" are currently more advanced active protection systems, and their protection capabilities have also been tested in actual combat. For the fourth-generation main battle tank, in order to obtain greater survivability, the application of active protection technology is imperative.

By analyzing the situation of active tanks in service, according to different protection mechanisms, active protection technology can be divided into soft-kill active protection system and hard-kill active protection system. The soft-kill active protection system mainly makes the anti-tank ammunition lose its direction and cannot accurately hit the target; the hard-kill active protection system destroys the anti-tank ammunition before it hits the target. From a technical point of view, the core technology of the soft-kill active protection system is multi-spectral optoelectronic detection and optoelectronic confrontation technology, and the core technology of the hard-kill active protection system is detection, tracking and identification technology and the development of interception devices.

In addition to active protection technology, reducing the height of the main battle tank and reducing the lateral size can also reduce the probability of the tank being hit to a certain extent.

Soft-kill active protection technology is mainly to interfere with and suppress the enemy’s observation and guidance systems, making it impossible for the enemy’s optoelectronic system to play its established combat effectiveness, or even destroy the enemy’s optoelectronic system. From the perspective of its functions, it should include detection systems, information processing systems, and interference or suppression systems.

The main forms of soft-kill active protection technology are warning, deception and interference, and suppression. Warning technology mainly refers to the warning system that warns the crew when the tank is locked by infrared, laser or other means, providing the crew with a certain amount of response time; deception and interference is to disrupt the missile’s lock by sending false signals and creating smoke when the anti-tank missile attacks: the suppression system uses lasers to temporarily or permanently disable the sensors in the enemy’s optoelectronic system.

As battlefield reconnaissance means become more and more diverse, the optoelectronic systems that soft-kill active protection technology has to fight against are also becoming more and more varied. In order to cope with complex battlefield environments, it is necessary to expand the scope of confrontation of soft-kill active protection technology, that is, to expand optoelectronic confrontation to the full band range as much as possible. At the same time, from the perspective of easy maintenance, the entire optoelectronic system including detection, processing, interference, command and other subsystems should be integrated into one.

Although the soft-kill protection system has excellent protection capabilities against guided weapons and can also cause damage to the optoelectronic systems of distant enemies, it cannot deal with unguided weapons and equipment such as rockets. At this time, hard-kill active protection technology is needed to make up for this defect. Compared with the soft-kill active protection system, the hard-kill active protection system not only needs a detection system to detect incoming weapons and equipment, but also needs powerful information processing and computing capabilities to quickly analyze and solve the control interception device to launch interception missiles in the correct and reasonable direction.

By analyzing the current interception missiles, the killing method of the interception missile is mainly prefabricated fragments or shock waves, and the interception missiles are shotguns, rockets or grenades. For the next generation of main battle tanks in the United States, which method to use will depend on technical conditions and combat conditions. For example, in urban street fighting, prefabricated fragments with stronger directional capabilities than shock waves have greater advantages and can better avoid accidental injuries to infantry accompanying the tanks. However, whether my country’s armored forces will be trapped in endless street security wars like the US military or will compete with the US military is a question worth considering. The two tasks are completely different.

In the 1970s and 1980s, the third-generation main battle tanks represented by Leopard 2, T-64, and M1 began to serve, but active protection technology was not integrated into the design of these tanks. For the third-generation main battle tanks, the installation of active protection technology is more based on the adaptation of the vehicle model. For the fourth-generation main battle tanks, the active protection system is the most effective means to improve protection when the weight is limited and the armor protection technology has not made major breakthroughs, and it can also meet the requirements of survivability proposed in this article. Therefore, the active protection system should be the standard configuration of the fourth-generation main battle tank, which requires the installation of the active protection system to be considered at the beginning of the design of the tank to ensure that the tank can be protected in all directions, especially on the top.

Whether it is a soft kill or hard kill active protection system, it should be adopted on the fourth-generation main battle tank to ensure that the active protection system can take corresponding countermeasures regardless of whether the incoming ammunition has a guidance system. At the same time, the current soft-kill active protection system is also developing in the direction of suppression and blinding, rather than just simple warning, interference and deception. In order to reduce the burden on the crew and fully coordinate the relationship between soft kill and hard kill, the active protection system should be highly automated and autonomous, and the crew should retain the highest control when necessary. In addition, a more powerful radar system should be adopted to increase the detection distance and detection accuracy of the active protection system, thereby providing more reaction time for the crew members. Since the tank turret is usually the most likely to be hit on the battlefield, reducing the size of the turret is also a way to reduce the hit rate. For the fourth-generation main battle tank, an unmanned turret will be a key technology. The issue of unmanned turrets will be discussed in detail later.

In short, in the design of the fourth-generation main battle tank, the design of the active protection system combining soft and hard kill and the good coordination with the vehicle will be one of the important research directions, so that the tank has omnidirectional protection capabilities. In addition to firing back at the enemy, the main battle tank’s active protection system can also counterattack through photoelectric suppression and blinding.

Armor protection technology

Unlike other types of armored vehicles, strong armor protection is necessary for main battle tanks to meet their requirements of resisting enemy firepower and breaking through enemy defenses. Limited by the size and weight of the main battle tank, the homogeneous steel armor on the front of the hull and turret is no more than 200 mm, and pure homogeneous steel armor has reached its end. In order to further enhance the protection capabilities of the main battle tank, composite armor and explosive reactive armor have become the mainstream armor of the main battle tank.

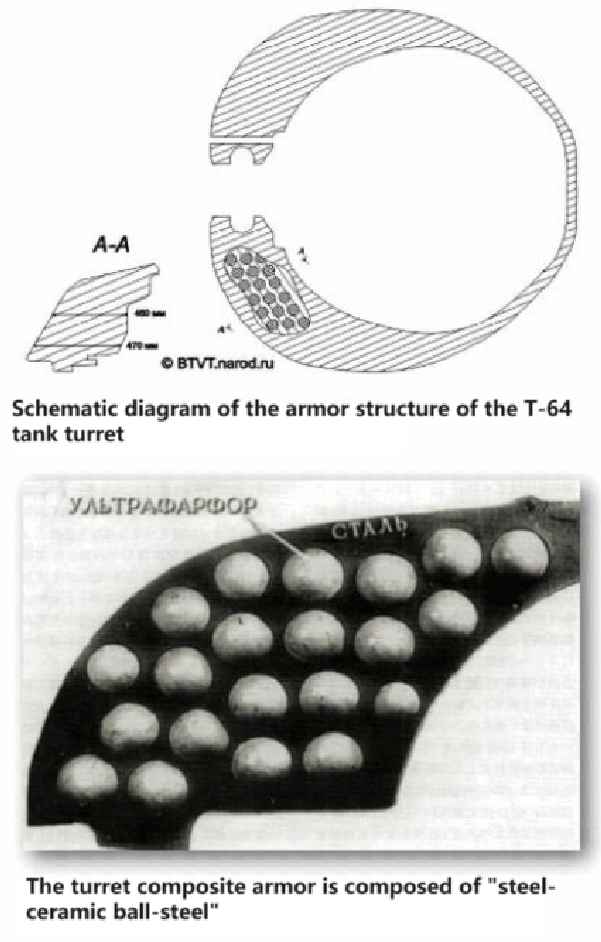

Composite armor has two meanings. The first is that the armor material is made of composite materials: the second is that the armor material structure uses a composite structure. Early composite armor, such as the composite armor used by the Soviet T-64 main battle tank, embedded "super ceramic balls" in the homogeneous steel armor in the turret to enhance its protection capabilities. Obviously, it mainly uses the second composite armor structure. As the first real main battle tank, the composite armor pioneered by T-64 gave the Soviet Union a huge advantage over Western main battle tanks in tank quality, and also officially marked that composite armor has become a rigid demand for armor protection of main battle tanks in the future. However, as the earliest composite armor, the composite armor used on T-64 is obviously backward. It is necessary for the next generation of main battle tanks to install a new generation of composite armor to counter the increasingly powerful anti-tank weapons and the attacks of enemy tank guns.

As an advanced high-tech material, ceramic material has the characteristics of high compressive strength, high hardness, corrosion resistance, high wear resistance and light weight, so it quickly became the preferred material for composite armor of main battle tanks. However, its toughness is poor, and it needs to be combined with metal materials such as steel with better toughness to achieve better protection capabilities.

The mainstream composite armor technologies today are ceramic reinforced metal matrix mean composite armor and ceramic/metal functional gradient composite armor. The former eliminates the obvious mutation interface between ceramic materials and metal materials, making the two truly integrated; the latter is a composite material with gradient changes along the thickness direction, and the obvious material mutation interface can exist or not. Obviously, the composite armor with thickness changes and no obvious material interface can fully combine the advantages of the two, so that the armor has a strong ability to resist single bullets and multiple strikes.

Explosive reactive armor was first put into use in the war when Israel invaded Lebanon in 1982, and its strong protection against armor-piercing shells was tested in actual combat. Explosive reactive armor has the characteristics of high anti-ballistic efficiency, light weight, low cost, easy loading and unloading, and good safety performance, so it has become an important part of the armor protection system of main battle tanks. Taking the Soviet Union’s "Contact" 1 explosive reactive armor as an example, it can provide 400 mm of protection against armor-piercing shells. Each explosive reactive armor container weighs only 5.3 kg, and its protection is 10 to 20 times that of homogeneous steel armor of the same mass. However, the early explosive reactive armor only has strong protection against the metal jet of armor-piercing shells, and has poor protection against kinetic shells. However, the large-scale application of fin-stabilized discarding sabot armor-piercing shells has made it the main type of shells for main battle tanks, and various types of anti-tank missiles are still mainly armor-piercing shells. Today’s main battle tanks can penetrate 900 mm of homogeneous steel armor by launching fin-stabilized discarding sabot armor-piercing shells, and anti-tank missiles such as Russia’s "Kornet" can penetrate 1200 mm of homogeneous steel armor. Therefore, it is necessary to develop heavy explosive reactive armor that has strong protection against both armor-piercing shells and armor-piercing shells. For example, thickening and weighting the throwing plate and back plate enables it to deflect or even twist off the long-rod armor-piercing shells.

In addition to the heavier explosive reactive armor, the metal jet that cuts or deflects the long-rod armor-piercing projectile and the metal jet that cuts the armor-piercing projectile with the metal jet is another mode of action of the explosive reactive armor. A reactive armor with a linear shaped charge structure was proposed in the master’s thesis "Research on the Anti-Penetration Mechanism of New Reactive Armor" of Beijing Institute of Technology. The shaped jet head, the two sides of the metal cover, and the pestle act on the high-speed tungsten rod respectively, causing the tungsten rod to be damaged or deflected to varying degrees. This method makes up for the disadvantage that the flat-plate reactive armor has an unsatisfactory protective effect against armor-piercing projectiles, and further improves the protective capability of the explosive reactive armor compared to the thickened throwing plate and back plate.

Although new concept armors such as electromagnetic armor have been proposed, due to cost, reliability and other reasons, electromagnetic armor is still unlikely to be used on main battle tanks in the future. Therefore, it can be foreseen that the armor of the next generation of main battle tanks will still be mainly composite armor, and the protective capability will be further enhanced by installing additional explosive reactive armor.

The composite armor technology of the next generation main battle tank should be constrained titanium-based ceramic composite armor or ceramic-metal functional gradient composite material. Regardless of the composite armor material, modular armor or armor steel constraining composite materials is a very likely way to ensure the repairability and replaceability of armor. However, when constrained composite armor is attacked by armor-piercing projectiles, the surrounding constrained materials will be squeezed. The greater the kinetic energy of the armor-piercing projectile, the greater the squeezing of the constrained materials will be, even exceeding the limit of armor steel. Therefore, strengthening the constrained materials is as important as the composite armor materials, such as optimizing the manufacturing technology of titanium alloys and reducing their costs so that they can be used on a large scale on the fourth generation main battle tanks.

In addition, new explosive reactive armor - especially heavy explosive reactive armor or shaped charge explosive reactive armor that can protect against armor-piercing projectiles and armor-piercing projectiles - should be adopted. In addition to installing it on the front and sides of the vehicle body to protect the crew, another important function is to strengthen the armor of the unmanned turret. The next generation of main battle tanks is very likely to use unmanned turrets, because it can greatly reduce the turret armor to strengthen the armor of the crew compartment located in the vehicle body. However, in order to install the active protection system and sighting equipment mentioned above, the turret cannot only expose the bolt and gun carriage. A certain amount of armor still needs to be installed on the turret to provide protection for the fragile sighting equipment, and too thick armor will weaken the weight reduction advantage of the unmanned turret. Therefore, the best solution is to use lightweight and highly protective explosive reactive armor on the unmanned turret, which can also be installed on the front and sides of the vehicle body to protect the crew. Therefore, more advanced explosive reactive armor will also become the standard of the next generation of main battle tanks.

In short, it can be foreseen that the armor protection of the next generation of main battle tanks will still be composite armor and explosive reactive armor. However, through technological advances, new titanium-based ceramic composite armor or ceramic-metal functional gradient composite materials, as well as heavy explosive reactive armor and shaped charge explosive reactive armor will be widely used on the fourth generation of main battle tanks.

Anti-secondary effect technology

No matter how powerful the active protection system and armor protection system of the main battle tank are, it is impossible to avoid being penetrated. Therefore, how to prevent the secondary effect after the main battle tank is penetrated and avoid casualties and losses of armored soldiers as a technical branch is also an important content under the guidance of the survivability concept of the next generation of main battle tanks.

Since the tank itself is a mobile fortress filled with fuel and shells in the combat state, after being penetrated, especially after being hit by the ammunition rack: whether the subsequent fire and detonation can be suppressed, and whether the shock wave after the detonation will cause harm to the crew, should be considered when designing the main battle tank.

For the next generation of main battle tanks, unmanned turrets will be an important feature. When unmanned turrets are realized, it will be easy to realize the compartmentalization of ammunition and the centralized arrangement of crew members.

After the armor of an armored vehicle is penetrated, the equipment damage and crew injury caused by fragments, as well as fires and ammunition explosions in the vehicle are collectively referred to as secondary effects. Unlike the armor-piercing shells widely used during World War II, the main means of killing crew members and equipment inside main battle tanks is the fragments produced after penetrating the armor. Therefore, preventing the generation of fragments, as well as preventing fires and even ammunition explosions, is a technology that the next generation of main battle tanks need to pay attention to.

Currently, the main means adopted by various types of armored vehicles to reduce the generation of fragments is to add armor linings inside the armor. The main materials of the armor lining are flexible polymers such as nylon, aramid or polyethylene, which reduce the number of fragments and slow down the speed of fragments through their good tensile strength and fireproof requirements.

And fire extinguishing and explosion suppression are also an important part of the main battle tank protection system. In the Soviet-German battlefield of World War II, the vast majority of the reasons for the irreparable loss of tanks of the Soviet armored forces were "complete burning", and the other two were "destruction" and "sympathetic explosion", which respectively refer to the irreversible damage of the tank and the direct explosion of the tank. Even today, the tank confrontation on the Soviet-German battlefield still has considerable reference value and significance for today’s tank design. The Soviet Union’s statistics on the reasons for irreparable losses of tanks show the importance of equipping tanks with fire extinguishing and explosion suppression devices. Therefore, from the perspective of survivability, it is very necessary to equip my country’s next generation of main battle tanks with more advanced fire extinguishing and explosion suppression devices. At present, for the fourth-generation main battle tanks, sensors should be reasonably arranged in the vehicle to detect whether there is a fire site in all directions without dead ends: the control system should be highly digitized; the fire extinguishing actuator uses a new type of fire extinguishing agent, such as ultra-fine dry powder fire extinguishing agent, fine water mist fire extinguishing agent, etc., and the fire extinguishing agent in the crew compartment must be harmless to the human body.

The unmanned turret should be the most important feature of the fourth-generation main battle tank. In addition to being able to use more powerful artillery and achieve a high degree of informatization and automation, its advantages in protection cannot be ignored. The unmanned turret makes it possible to completely separate and compartmentalize the crew and ammunition. Even if the ammunition rack is hit, it is difficult to cause direct damage to the crew.

For unmanned turret technology, its main sub-techniques are artillery control technology, information transmission of sighting equipment, and ammunition feeding technology. Thanks to the current progress of electronic technology, the gunner can control the artillery outside the turret, and the commander can discover the target or even control the artillery through the sighting equipment installed on the turret. There is no longer an insurmountable technical gap in principle and theory. The ammunition feeding technology can completely adopt a wheel-type automatic loader similar to the 96-type and 99-type, and its reliability has been fully verified. In general, with China’s current level of science and technology, especially electronic technology, it is completely feasible to realize unmanned remote control turrets. It is precisely because of the unmanned turret that all crew members can fight in the well-protected and heavily armored crew cabin, protecting the crew members from harm to the maximum extent. Therefore, the unmanned turret brings significant improvements in survivability and overall combat capability to the next generation of main battle tanks. No matter from which perspective, unmanned turret technology will be an important technical feature of my country’s next generation of main battle tanks.

From the above, we can know that more advanced fire extinguishing, explosion suppression and anti-shedding linings will be used on the next generation of main battle tanks to improve the survivability of their crew. In addition, the most important point is the unmanned turret that the fourth generation of main battle tanks must use. The ammunition compartment brought by the unmanned turret will be an epoch-making improvement in the survivability of the main battle tank. Even if the ammunition explodes, the crew in the crew compartment will not be seriously injured by properly setting the pressure relief plate, reducing the casualties of excellent armored soldiers.

Conclusion

For the next generation of main battle tanks, it is more appropriate to replace "protection capability" with "survivability", which should include the following four aspects:

The tank is not easy to be discovered;

2The tank is not easy to be hit after being discovered;

3. The tank is not easy to be penetrated after being hit;

4. The tank is not easy to cause casualties after being penetrated.

Among them, the first point is mainly achieved through camouflage and concealment, the second point is achieved through interference and active protection, the third point is mainly achieved through more powerful and advanced armor, and the fourth point is mainly achieved through concentrated crew deployment and ammunition compartments.

After the analysis in the previous article, from the above four perspectives, the main technical features that the next generation of main battle tanks should have are as follows:

1. The tank is not easy to be discovered. The main implementation technology is mainly phase change materials, supplemented by adaptive camouflage technology with certain variable technology, and the coating form should be digital camouflage.

2. The tank is not easy to be hit after being discovered. The main implementation technology is an active protection system that combines soft and hard kills, and it develops towards confrontational trends such as suppression and blinding.

3. The tank is not easy to be penetrated after being hit. The main implementation technology is a new type of titanium-based ceramic composite armor or ceramic-metal functional gradient composite material, as well as heavy explosive reactive armor and shaped charge explosive reactive armor

4. After the tank is penetrated, it is not easy to cause casualties. The main technologies to achieve this are more advanced fire extinguishing, explosion suppression and anti-shedding lining, as well as the most important and critical unmanned turret technology.

To summarize the main technical features of the next generation of main battle tanks in terms of protection technology in one sentence, it should be the strong concealment capability or anti-reconnaissance capability brought by adaptive camouflage based on phase change materials, the anti-hit capability with the active protection system combining soft and hard kill as the core, the anti-penetration capability with new composite armor and explosive reactive armor as the core, and the anti-secondary effect capability with unmanned turret as the core, supplemented by fire extinguishing, explosion suppression and anti-shedding lining.