Unconsciously, the Russian-Ukrainian conflict has lasted for more than a year. In this protracted war, the mechanized forces of both sides suffered heavy losses. Some battlefield photos of Russian tanks being blown apart have been widely circulated on the Internet media, which not only shows the cruelty and fierceness of the war, but also seems to confirm a point of view: the turntable automatic loader used by the Soviet and Russian third-generation main battle tanks cannot physically isolate the ammunition from the fighting compartment, so once the anti-tank ammunition penetrates the armor, it is particularly easy to cause the ammunition to explode and blow up the turret.

However, is this really the case? Should the turntable automatic loader really bear the main responsibility for the "flying turret"?

Dangerous factors

Modern anti-tank ammunition mainly includes tail-stabilized armor-piercing projectiles, armor-piercing projectiles, and self-forged projectiles. The armor-breaking projectiles are becoming increasingly declining because they are difficult to deal with composite armor. However, whether it is the armor-piercing body of the fin-stabilized discarding sabot armor-piercing projectile, the pestle formed by the self-forged projectile, the metal jet formed by the armor-piercing projectile, or the fragments of the fragmentation projectile that fall off the back of the tank armor, they can all destroy the equipment inside the tank and kill the people inside the vehicle. This kind of damage effect that directly destroys objects and injures people is called the primary killing effect.

Among the above-mentioned types of projectiles, the primary killing effect produced by the fin-stabilized discarding sabot armor-piercing projectile is the most terrifying, and it is essentially a self-forged projectile that belongs to the armor-piercing projectile family. Secondly, the primary killing effect of the armor-piercing projectile is relatively poor. As for the fragmentation projectiles that once had a glorious time and were likely to replace both grenades and armor-piercing projectiles, they can no longer pose a major threat to tanks after the popularization of composite armor. However, for tanks, when the armor is penetrated by anti-tank ammunition, the armor-piercing body or the shaped metal jet carries a large number of armor fragments and splashes at high speed inside the tank. The direct killing means such as fragments and overpressure that damage equipment and kill the crew are only a small part of the killing effect. The greater damage is that the hot armor fragments or metal jets destroy the hydraulic equipment pipelines and fuel pipelines, causing high-pressure hydraulic oil or fuel to leak and vaporize, and then cause oil and gas fires. Flames or hot fragments and metal jets can also cause the main gun ammunition of the tank stored in the vehicle to explode, that is, the secondary killing effect. Only when the secondary killing effect is triggered can the tank turret be blown away.

Early tanks are generally equipped with gasoline engines. The highly volatile gasoline is stored in various large and small fuel tanks that are placed wherever there is a gap. Therefore, after a while, a pungent gasoline mist will permeate the tank body. If the ventilation conditions are not good, the tank crew members lighting cigarettes in the car illegally can easily cause the oil mist in the car to explode into a fireball, not to mention the secondary effects caused by various anti-tank ammunition penetrating the armor. Of course, modern tanks mostly use diesel or even kerosene as fuel, which is much safer than gasoline. However, diesel and kerosene also have a certain volatility, but not as strong as gasoline. If the temperature inside the car is high enough, the diesel and kerosene mist exceeds a certain concentration and will still be ignited.

Early tanks and the first and second generation main battle tanks after the war are all driven by hydraulic systems to drive the turret and gun control device. The control system, transmission system, and backup emergency system also rely on hydraulic devices to transmit force. There are also many hydraulic systems on the third generation main battle tanks. Therefore, various pipelines, pump lines and cylinders for hydraulic oil storage, as well as lubricating oil tanks and oil lines of the hydraulic system are distributed inside the tank. Hydraulic oil and lubricating oil are also flammable. As for the inevitable plastic handles, oily buffer sponges, insulating skins on various power and signal control lines, rubber seals, etc. inside the tank, they may also react chemically when exposed to heat. Of course, compared with the main gun ammunition stored inside the tank, these sources of danger are relatively light.

Among the various types of ammunition for the main gun, grenades and armor-piercing shells are filled with explosives. Although modern military explosives are striving to reduce insensitivity while pursuing power, the insensitivity of some high explosives can even reach the level of being directly hit by bullets without being detonated, but the propellant of tank main gun ammunition cannot achieve such insensitivity, and basically ignites at the touch of a button.

In addition, with the advancement of technology, modern tank main gun ammunition mostly uses semi-combustible cartridges. The main components of the cartridge are a mixture of inert fiber, nitrocellulose, diphenylamine, resin, etc. Among them, nitrocellulose itself is an important component of various propellants and will burn when exposed to fire. Once a fire caused by a secondary killing effect occurs, the semi-combustible cartridge will be ignited, causing the propellant to burn violently. The continuous high temperature will trigger the action of the ammunition fuse and detonate the explosives loaded in the ammunition.

The semi-combustible cartridges used in the Soviet 2A46 series 125mm tank guns are mainly composed of nitrocellulose, paper fiber, adhesive and diphenylamine stabilizer. The adhesive is mainly a copolymer emulsion of vinyl acetate, polyvinyl alcohol formal and other materials. To prevent moisture and microbial erosion, a layer of oil film is also coated on the outer surface of the cartridge. This cartridge has the advantages of low combustion residue, high reliability and ease of use, but the content of nitrocellulose and paper fiber is too high, so there is a possibility of fire and combustion at lower ambient temperatures.

In contrast, the shell of the semi-combustible cartridges used in Western tanks is often mixed with aluminum metal fibers to increase the strength of the projectile. More importantly, the West has mixed mesh metal fibers and improved inert fibers to make the outer wrapping tube of the semi-combustible cartridge, which can not only meet the requirements of effective combustion of the cartridge in the chamber, but also ensure that the cartridge will not be ignited within a certain temperature range.

In order to further protect the ammunition, many types of tanks have made the main gun ammunition storage rack into a sandwich structure commonly known as a "water jacket", which is filled with fire extinguishing agent to reduce the possibility of ammunition explosion. However, the capacity of the "water jacket" sandwich is extremely limited, and the fire extinguishing agent can only flow out and play a very limited role after being broken by external force. If the internal fire of the tank caused by the secondary killing effect spreads to the ammunition storage rack, I am afraid that the ammunition will explode before the fire burns through the "water jacket".

Layout advantages and disadvantages

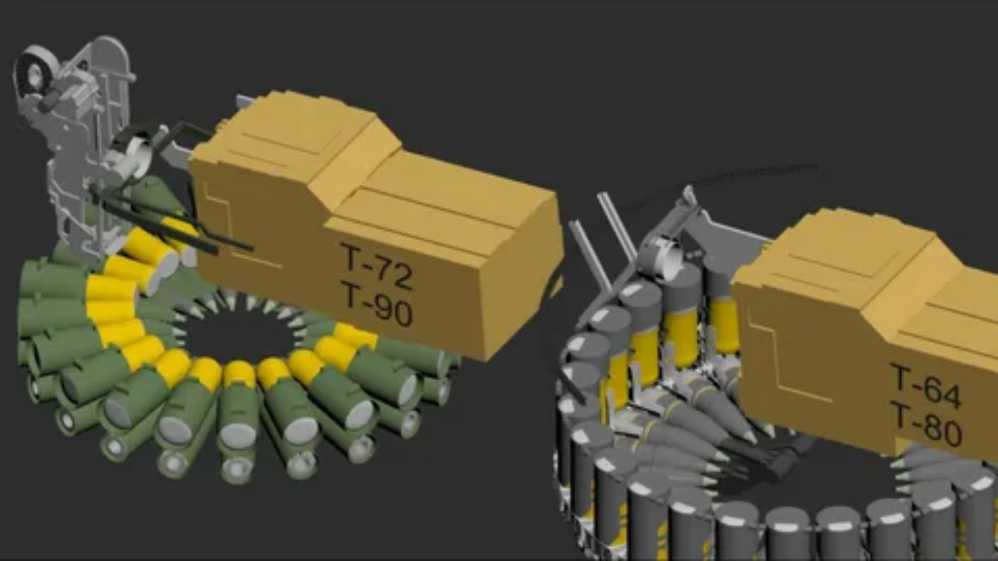

Because of the serious internal friction of the major tank research and development units in the Soviet Union in history, the Soviet Army’s third-generation main battle tanks actually developed three major series, T-64, T-72 and T-80. Each series also derived several or even more than ten sub-models, which brought endless troubles to the logistics support of the troops. After the disintegration of the Soviet Union, Russia grafted the turret of the T-80 series onto the T-72 chassis and developed the T-90 as a unified tank, hoping to end the passive situation of complicated tank models and difficult support.

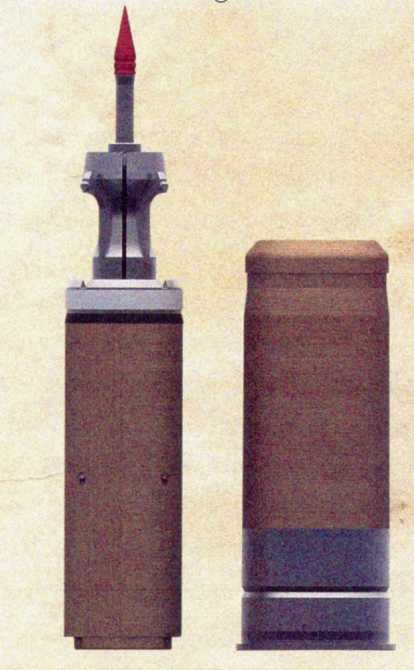

The above four series of Soviet and Russian tanks all use turntable automatic loaders. Although there are differences in specific structures, the storage method of main gun ammunition is basically the same. Taking the T-72 tank, which is equipped with the largest number of equipment and exports, as an example, it carries 39 rounds of main gun ammunition, and the model ratio is generally 12 rounds of fin-stabilized armor-piercing shells, 21 rounds of fin-stabilized grenades, and 6 rounds of fin-stabilized armor-piercing shells. Among them, 22 rounds of projectiles and their matching semi-combustible cartridges are stored in the turntable automatic loader, and are stored in two layers, the upper layer is the cartridge, and the lower layer is the projectile. In addition, there are 9 rounds of shells stored on the ammunition rack behind the turret basket, 4 rounds of shells are stored on the right side of the driver at the front of the vehicle body, and 4 rounds of shells are stored on the rotating floor of the fighting compartment. Among them, 3 rounds are stored upright and the other 1 is lying.

Although as much as 56.4% of the main gun ammunition is stored in the turntable automatic loader, the commander and gunner are actually "sitting" on a pile of shells, but the Soviet Union does not think that such an arrangement will make the tank safer than similar Western products. The reason is that the automatic loader is located on the bottom plate in the middle of the vehicle body. This position is very low, only about 0.3~0.4 meters above the ground. Not only is the possibility of being directly hit by anti-tank ammunition extremely low, but the automatic loader is also protected by the vehicle body and the armor of various parts of the turret. Even if the relatively weak top armor of the turret is broken by the popular top attack ammunition, the main gun breech device and various in-vehicle equipment and facilities in the fighting room can also provide a certain shield for the automatic loader to avoid being directly hit by the automatic loader’s ammunition storage mechanism, which will then cause the ammunition to explode.

Some people believe that the turntable automatic loader cannot be physically isolated from the fighting room, but in fact, this is not technically impossible, but it is meaningless to do so, or it is not worth the loss. Because even if it costs a lot to achieve physical isolation between the turntable automatic loader and the fighting compartment, once the automatic ammunition loading program is started, this physical isolation will inevitably be destroyed. In other words, this physical isolation can only be achieved when the tank is in a non-combat state, but what is the practical significance of this? To put it another way, even if the turntable automatic loader and the fighting compartment are in a physical isolation state when the tank is penetrated, the spare ammunition stored in various places in the vehicle still has the risk of explosion.

The view that the frequent "flying turrets" of Soviet and Russian tanks are attributed to the turntable automatic loader, and at the same time, the turret tail ammunition compartment design commonly used in Western tanks is highly praised, believing that this will greatly reduce the damage to the crew caused by the secondary killing effect after the tank is hit is quite debatable.

First of all, the primary reason why Western tanks generally set up ammunition bays at the rear of the turret is not to improve the survivability of the tank, but to try to keep the turret balanced. As we all know, no matter which tank it is, the armor on the front of the turret is the thickest. While the thick armor provides super strong protection, it also makes the center of gravity of the turret move forward sharply. In addition, the barrel of the main gun of modern tanks is long and heavy, which makes the center of gravity of the turret move forward further. If no technical compensation measures are taken, it will be particularly difficult to rotate the turret. Especially when starting from a standstill, it will be particularly stuck, which is very easy to miss the opportunity. If the tank is located on a slope, it is even difficult to rotate the turret in serious cases. At the end of World War II, when Britain replaced the American-made M4 "Sherman" tank with a 17-pound tank gun developed by the country and converted it into the "Firefly" tank, the weight of the gun barrel increased sharply from more than 400 kilograms to more than 900 kilograms, so it had to weld a storage box at the rear of the tank turret and put more than 1 ton of iron blocks in it as counterweights to keep the turret balanced. These iron blocks have no other use and are "dead weights", so they were later replaced by the turret rear ammunition bay. Secondly, the turret rear ammunition bay of Western tanks cannot accommodate all the main gun ammunition. Take the Western post-war second-generation main battle tank "Leopard" 1 as an example. Although it has a huge turret rear compartment, it only has 13 rounds of 105mm main gun ammunition stored in it, and the remaining 42 rounds of ammunition are stored in the body of the vehicle. Of course, the capacity of the turret rear ammunition bay of the Western post-war third-generation main battle tank is significantly higher than that of the second-generation main battle tank, but a considerable part of the main gun ammunition still has to be stored in the body of the vehicle. Among them, the American M1 series main battle tanks, starting from the M1A1, only have 6 rounds of main gun ammunition stored on the ammunition rack below the right side of the turret, which is the least. The German Leopard 2, French Leclerc, Italian C1 Ram, Korean K2, Japanese Type 90 and Type 10 main battle tanks have 27, 18, 27, 24, 24 and 21 rounds of main gun ammunition stored in the body respectively. These considerable numbers of ammunition cannot be physically isolated from the fighting compartment. Once they are directly hit by anti-tank ammunition or spread by oil and gas fires in the vehicle, they will still explode.

Third, and most importantly, among all types of Western tanks, only the rear ammunition compartment of the M1 series tank turret can be regarded as theoretically "physically isolated" from the fighting compartment in a certain sense. Western media have praised the composite explosion-proof plate driven by an electric motor between the rear ammunition compartment and the fighting compartment of the MI series tank turret after the M1A1. But in fact, the symbolic significance of this explosion-proof plate is far greater than its practical significance, and it is a commercial publicity gimmick. Because this explosion-proof plate made of composite materials is very thin, it is probably difficult to withstand the shock wave generated by the powerful main gun ammunition explosion. The US military operating specifications require that when the loader takes the bullet, he must use his knee to hold the explosion-proof door switch during the entire process of taking the bullet. Once the knee releases the switch, the explosion-proof door will automatically close. Based on the information disclosed by various channels in recent years, the explosion-proof door often fails to close normally during actual use. This may be due to a failure of the relevant electromechanical system during frequent use, or it may be because the loader finds it troublesome and uses items such as crowbars and wrenches to hold the explosion-proof door switch to facilitate his own ammunition retrieval.

Not only that, for tanks, the threat directions of enemy anti-tank ammunition are from the front, side, top, tail and bottom from high to low. Therefore, the armor of the turret tail compartment is relatively weak, whether on the side, top or rear. For the M1 series tanks, the size of the turret tail compartment is about 1 meter long, nearly 2 meters wide, and about 0.5 meters high. The thickness of its side, top and tail armor does not exceed 50 mm, especially the two pressure relief plates on the top of the compartment. From the public video, it can be said to be surprisingly thin, and it can be easily penetrated by various anti-tank ammunition without any suspense. In addition, from a bird’s-eye view, the ammunition bay at the rear of this turret is right next to the engine compartment with an extremely obvious infrared signal feature, and it is easy to be hit by the warhead of the terminal-sensitive projectile. Once the main gun ammunition stored in it explodes, it will not only affect the fighting room and the power compartment, making the tank completely lose its combat capability, but also the thin explosion-proof door will definitely not protect the crew. Previously, the photos of the "flying turret" of the M1 series tank were rare.

First, the army equipped with this type of tank has a strong position in the various local wars that have occurred in the past 30 years, with a comprehensive advantage in the combat system, and has fought fewer defeats;

Second, some photos were blocked by countries with media hegemony

However, as Saudi Arabia’s relations with the West, especially with the United States, have undergone a series of subtle changes, people can see photos of the M1A2S main battle tank equipped by the Saudi army being "beheaded" by the Yemeni Houthi armed forces. Although the export tank must be technically downgraded based on the US military’s own model, this downgrade is generally concentrated on the power of ammunition, armor material and thickness, as well as vehicle-mounted equipment and engines. The original design of the pressure relief plate and explosion-proof door of the tail ammunition compartment is already thin enough, how can it be downgraded?

In summary, the original intentions of the Soviet-Russian favorite turntable automatic loader and the Western turret tail ammunition compartment design have their own emphasis, and their advantages and disadvantages are equally prominent. It is hard to say which design has more advantages. Which design to adopt depends on technical and tactical requirements and comprehensive considerations.

Sensor gap

The turntable automatic loader is the "culprit" of the Soviet-Russian tank "flying turret". This view has been circulated since the end of the Gulf War in 1991. But in fact, the Iraqi army, which was defeated in this war, was actually defeated by the 38-day high-intensity air strikes of the coalition forces. There are very few examples of direct confrontation between the mechanized forces of both sides. Even if there were, Iraq’s mechanized forces were under the dimensionality reduction attack of the combat system being crushed by the opponent in all directions, and failure was inevitable. Therefore, the phenomenon of "flying turrets" after the tanks were destroyed was common. However, in this one-sided war, the M1A1 tanks equipped by the US military were also completely destroyed by the Iraqi monkey version of the T-72. However, due to the extremely strict wartime public opinion control of the US military, the photos of the MIA1 being destroyed and even the "flying turret" were not exposed by the media until the late 1990s, and the circulation was not wide.

In the second decade of the 21st century, the M1A2S main battle tanks equipped by the Saudi Arabian army were also "separated from their heads" on the battlefield in Yemen. The "Leopard" 2 main battle tanks equipped by the Turkish army not only "flew the turret" when they crossed the border to attack the Kurdish Workers’ Party armed forces, but also the huge body was exploded back to the state of parts. Through the above analysis, it is not difficult to find that whether it is Soviet tanks or Western tanks, their obviously different ammunition storage methods have the possibility of ammunition explosion.

But objectively speaking, the cases of "flying turrets" of Soviet tanks in the past 30 years are indeed significantly more than those of Western tanks. The author believes that the real reason for this phenomenon is that the comprehensive performance of the automatic fire extinguishing and explosion suppression system of Soviet tanks is significantly lower than that of similar Western products.

The design principle of the automatic fire extinguishing and explosion suppression system of tanks is not complicated. It is nothing more than the automatic control box autonomously analyzing the alarm signal sent from the sensor, judging the intensity of the fire, dividing the danger level, and controlling the amount and intensity of the fire extinguishing agent released by the fire extinguisher bottle. The fire extinguishing agent has both fire extinguishing and explosion suppression functions. Among them, explosion suppression mainly relies on reducing the surface temperature of combustibles and explosives, and fire extinguishing has three technical ways to achieve it: cutting off the oxygen supply of the burning material, reducing its surface temperature or participating in its combustion reaction, thereby greatly reducing its activity, and thus stopping the combustion reaction.

In terms of the performance of the fire extinguishing agent, Soviet tanks are not inferior to Western tanks, but the level of sensors is very different. According to public information, today, the Soviet tank automatic fire extinguishing and explosion suppression system still uses a large number of bimetallic or thermocouple sensors.

A bimetallic sensor is a sensor that welds two metals with significantly different expansion coefficients together, fixes one end, and allows the other end to expand freely after being heated. Since the metal sheet with a larger expansion coefficient expands more after being heated, the bimetallic strip will bend toward the metal sheet with a smaller expansion coefficient. The higher the temperature, the greater the degree of bending. The response speed of this sensor depends on the expansion speed of the metal, so the response speed is as high as several seconds or even tens of seconds, which can no longer meet the fire prevention and explosion suppression needs of modern tanks.

A thermocouple sensor is a sensor that welds two conductors or semiconductors made of different materials together to form a closed loop. When a temperature difference occurs between two conductors or semiconductors, an electromotive force is formed between the two, and then a current is generated in the loop. This phenomenon is called the thermoelectric effect or Seebeck effect. The response time of a thermocouple sensor is between hundreds of milliseconds and several seconds, which is significantly improved compared to a bimetallic sensor, but it is still not ideal. Because research shows that the time interval from the tank being penetrated to the secondary killing effect is roughly between 200 and 300 milliseconds. It is very likely that the thermocouple sensor has just sensed the temperature difference and has not had time to send a signal to the automatic control box, or has just sent a signal, but the automatic control box has not had time to react and start the fire extinguisher, and the secondary killing effect has occurred.

In contrast, the automatic fire extinguishing and explosion suppression system of the third-generation main battle tanks in the West has generally adopted dual-spectrum or even multi-spectrum photoelectric sensors. Through spectral analysis, people have found that when a substance burns, it will radiate ultraviolet, visible light, infrared and other light waves to varying degrees. Different fuels will have different wavelengths of radiated light waves. Different combustion conditions will also result in different detectability of flame radiation light waves in different wavelengths. After in-depth research, it was found that the spectrum of flames spans three spectral bands: ultraviolet, visible light and infrared. Therefore, people tried to use infrared sensors or ultraviolet sensors to detect the infrared radiation spectrum or ultraviolet radiation spectrum of flames, and used spectral analysis techniques to determine the brightness, flickering frequency, average radiation intensity and temperature of flames.

Since infrared and ultraviolet rays propagate at the speed of light, the response speed of photoelectric sensors can be compressed to between 5 and 15 milliseconds, which can well meet the needs of tank automatic fire extinguishing and explosion suppression systems. However, although the rapid response is gratifying, being too sensitive also brings the trouble of too high false alarm rate. The sunlight shining into the fighting room after opening the roof hatch, the spotlight in the car that suddenly turns on, the hot cartridges that are ejected after opening the gun door, and even the crew using a lighter may trigger false alarms of early photoelectric sensors. If the automatic control box "unthinkingly" accepts the alarm signal, and activates the fire extinguisher valve when there is no fire in the vehicle, the fire extinguishing agent that instantly fills the entire combat room can cause suffocation and death of the crew in serious cases. In view of this, Western countries have arranged dual-spectrum or even multi-spectrum photoelectric sensors at the same detection point inside the tank, and through simultaneous detection of infrared and ultraviolet band signals, several pieces of information are compared to eliminate false alarm information, reduce the system false alarm rate, and achieve good results.

Conclusion

It is reported that the reaction speed of the automatic fire extinguishing and explosion suppression system sensors of the T-64/T-72/T-80 series tanks is as high as several seconds. Even the T-72B3 and T-90 tanks modified with thermocouple sensors have a reaction speed of only seconds. In addition, before the advent of the T-72B3 and T-90 tanks, the duct-type fire extinguisher commonly used by Soviet tanks took about 10 seconds to spray a single bottle. It can only play the role of automatic fire extinguishing, but it is difficult to prevent the occurrence of fire. Therefore, once the tank is penetrated by anti-tank ammunition, the probability of the main gun ammunition in the vehicle exploding is high.

On the other hand, even the AFEDSS automatic fire extinguishing and explosion suppression system developed by Spectronix in Israel in the late 1970s has a photoelectric sensor reaction time of only 5 milliseconds, and a direct-injection fire extinguisher takes only about 0.1 seconds to complete a single-bottle spray. Moreover, 90% of the extinguishing agent sprayed is liquid, which vaporizes immediately after spraying. During the vaporization process, it can absorb a large amount of heat, so it can kill the fire in the bud in a very short time and prevent it from developing into a fire. The fire extinguishing and explosion suppression effect is far better than similar products of the Soviet Union and Russia. Please note that this is only the level of the West in the late 1970s, and the T-72B3 and T-90 may not be able to catch up, let alone surpass it.

In summary, the lagging of the automatic fire extinguishing and explosion suppression system is the fundamental reason why Soviet and Russian tanks are prone to "flying turrets" after being hit. The reason why the performance of this important system related to the safety of tanks is low is related to the low level of Soviet and Russian basic industry, especially the low level of precision measurement.