When the plane flies across the sky, a white track will be left on the blue background. However, behind this romantic scene, the roaring aircraft engine is continuously spraying exhaust gas to the outside world. The tiny particles in the exhaust gas cause the condensation of water vapor in the air, which forms the white track you can see. Even after the smoke disappears, greenhouse gases and harmful substances such as carbon dioxide, carbon monoxide and ammonia oxides (NOx) remain in the air, becoming the driving force of environmental damage. With people’s attention to environmental protection, the clean and efficient innovation of aviation power is imminent.

The undisputed environmentally friendly fuel: hydrogen

If you want to select the most environmentally friendly fuel, I am afraid that almost everyone will blurt out: hydrogen fuel.

As the simplest substance, hydrogen, or liquid hydrogen converted under low temperature and high pressure, produces only water after reacting with oxygen. Therefore, with hydrogen as fuel and oxygen in the air as oxidant, the reaction between the two can obtain a large amount of energy without producing carbon dioxide.

In fact, not only in the aviation industry, hydrogen fuel has always been a clean energy source that has attracted the attention of the scientific research and industrial communities. It is an ideal choice for alternative fuels in the automotive and gas turbine industries.

As for how to use hydrogen fuel to generate energy, there are currently two main ways. The first is to generate electricity through hydrogen fuel cells to drive electric motors; the second is to use hydrogen as fuel to drive the engine.

Based on hydrogen fuel cells to generate electricity, making aircraft "fully electrified" will undoubtedly bring many advantages in operation and maintenance. However, considering that the power required to drive an aircraft, especially a large aircraft, to take off can even be equivalent to a small power station, it will bring great difficulties to the transmission, management, and storage of electricity, especially for aircraft. Every inch of land is valuable, which is a task that is almost impossible to accomplish at present. Obviously, it is a big step to change all traditional "oil planes" into "electric planes".

Therefore, based on the basic structure of traditional aviation gas turbine engines, replacing oil with hydrogen fuel and driving the engine through the large amount of energy generated by combustion is more in line with the current technical level. After all, in basic principle, aviation gas turbine engines are essentially a kind of heat engine. During the working process, they will go through several processes such as "compressing air"-"mixing compressed air and fuel"-"igniting the air-fuel mixture"-"using high-temperature gas to generate power"-"exhaust gas". In the above process, it is not difficult to change the fuel from traditional oil to hydrogen fuel in principle.

Hydrogen fuel gas turbine engine

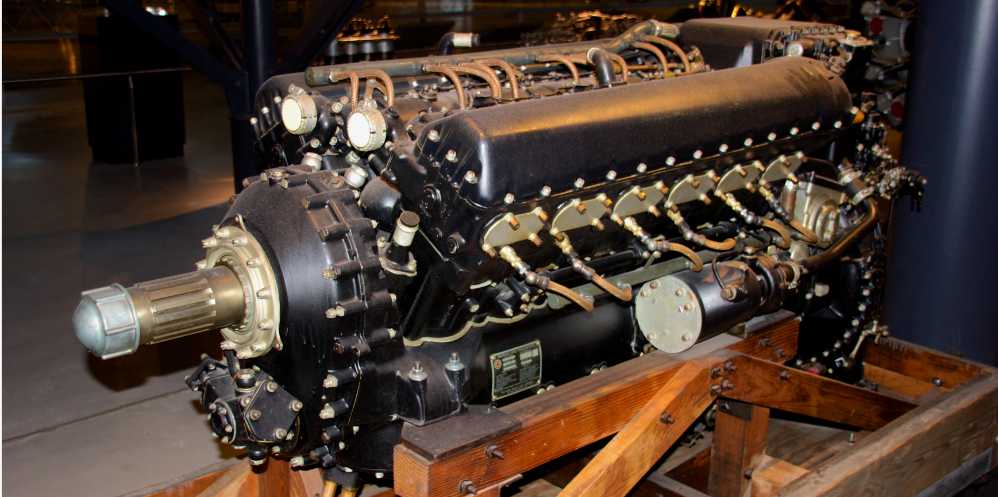

The old story of the United States and the Soviet Union Hydrogen fuel gas turbine engine is not new. In fact, as early as 1957, the predecessor of the National Aeronautics and Space Administration (NASA), the National Advisory Committee for Aeronautics (NACA), had already used hydrogen fuel to drive the B-57B aircraft for test flights.

However, the United States tried to use hydrogen energy to drive the aircraft not for environmental considerations, but to allow the aircraft to fly to a higher altitude for high-altitude reconnaissance. Therefore, the two J65 turbojet engines of this B-57B have been modified to use both traditional aviation kerosene and liquid hydrogen as fuel. During takeoff, both engines are supplied with traditional aviation kerosene until they reach an altitude of 50,000 feet (about 15 kilometers), when one of the engines will switch the fuel to liquid hydrogen to adapt to the high-altitude environment.

The test flight lasted only 20 minutes. After the test flight was successful, the US military believed that the demand for high-altitude flight was not so strong and stopped the continued development of hydrogen-powered aircraft. Therefore, it was the old rival of the United States, the Soviet Union, that truly realized the normalization of hydrogen-fueled turbine engine flight.

On April 15, 1988, a modified Soviet Tu-154 aircraft (later called Tu-155) successfully completed a test flight and carried out more than 100 flight missions afterwards, which shows that it has a certain degree of maturity. The aircraft originally had three NK-8 turbofan engines, only one of which was modified to use liquid hydrogen as fuel (later called NK-88).

Similar to the United States, the Soviet Union’s sudden idea of using liquid hydrogen as aircraft fuel was not for environmental considerations, but because the scientific community at the time generally believed that oil would be exhausted in the 21st century, so it was necessary to find alternative fuels. Hydrogen can be obtained by water electrolysis. As long as nuclear power plants can continue to output energy, it can be said that it is inexhaustible. For the same purpose, the Soviet Union also tested the use of natural gas as aviation fuel the year after the successful test flight of the hydrogen-powered aircraft.

It can be seen that although it is not for environmental protection, hydrogen fuel has been used to drive aviation gas turbine engines, which has preliminarily verified the feasibility of this solution from a technical point of view.

Old wine in a new bottle in the 21st century

The United States and the Soviet Union were early starters in hydrogen-powered aircraft, but the aviation industry was not well developed at that time, and the exhaust gas from aircraft engines was negligible compared to the emissions from the industrial and automotive industries. Moreover, people did not realize the importance of environmental protection to our living environment, so the United States and the Soviet Union did not continue on this path.

However, after entering the new century, both the explosive growth of the aviation industry and the awakening of people’s environmental awareness have prompted hydrogen fuel to reappear in a new form as an environmentally friendly fuel, and this time the leader is the European Union.

In May 2020, the European Union released a research report entitled "Hydro-gen-Powered Aviation". The report is part of the EU’s "Clean Sky" aviation emission reduction master plan, demonstrating that hydrogen-powered propulsion has "significant but underestimated" potential in reducing the impact of the aviation industry on the climate and achieving decarbonization goals, and proposed the need to significantly increase long-term research and innovation activities in hydrogen-powered aviation. At the same time, it is also necessary to formulate a long-term policy framework to ensure the growth of the industry, which can be regarded as setting the tone for hydrogen aviation from the top-level planning.

In addition, the UK released the "National Hydrogen Strategy" (UK Hydrogen Strategy) in August 2021, proposing to become a global leader in hydrogen energy by 2030; the United States released the "Department of Energy Hydrogen Program Plan" in November 2020, proposing to carry out hydrogen energy research in the next 10 years or even longer. my country also proposed "promoting the construction of hydrogen refueling facilities" for the first time in the 2019 government report. Therefore, the importance of hydrogen energy to domestic and foreign officials can be seen.

Aviation-related companies are more sensitive to the smell, and the research on hydrogen energy in emission reduction has started earlier. For example, Airbus started research on hydrogen-powered test equipment as early as 2016, and released three hydrogen-powered aircraft solutions called ZEROe in September 2020, all of which were powered by turbofan or turboprop engines driven by hydrogen fuel.

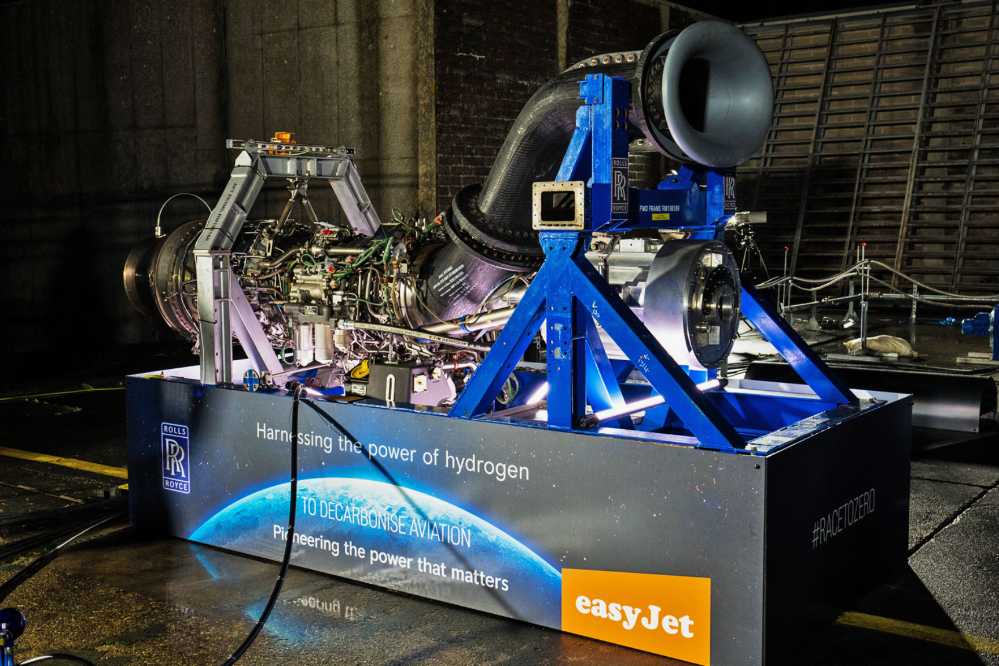

Rolls-Royce is a relatively quick aviation engine company to come up with real products

In December 2022, Rolls-Royce announced that they had successfully driven their own AE-2100A turboprop engine with hydrogen fuel, and this engine and its series models are frequently used in regional airliners. However, compared with the early hydrogen-fueled gas turbine engines of the United States and the Soviet Union, this new engine does not seem to have any unique skills, and it only confirms the feasibility of hydrogen as a fuel.

Interestingly, Rolls-Royce was very cautious in its publicity, emphasizing that this was "the first time a modern aircraft engine has run on hydrogen as fuel." But if you think about it carefully, an engine from the 1980s is probably only a little more "modern" than the NK-88 from the 1960s and the J65 from the 1950s. So, even though hydrogen-fueled gas turbine engines are getting attention today, and Rolls-Royce has produced a real product, achieving a "milestone" in hydrogen-powered aircraft, we still have a long way to go before we can really use hydrogen to drive aircraft.

Imperfect hydrogen fuel

When we first came into contact with the combustion reaction of hydrogen and oxygen, everyone would marvel at why there is such a perfect fuel in the world: hydrogen has a very high calorific value, can generate a lot of heat, and the reaction product is only water vapor. And most importantly, the water generated by the reaction can also be regenerated into hydrogen and oxygen under electrolysis, so as long as there is electricity, hydrogen fuel can be said to be endless.

However, how come no one uses such a perfect fuel?

This fuel is efficient, but not efficient

The calorific value of hydrogen is indeed very high, reaching 142 million joules/kg. In comparison, the calorific values of coal and gasoline are only 15-32 million joules/kg and 47 million joules/kg respectively, a huge gap, thanks to the extremely small relative atomic mass of hydrogen. So it is not wrong to say that hydrogen fuel is an efficient fuel.

However, please note the unit of the calorific value above: million joules/kg, which means that each kilogram of hydrogen can generate 142 million joules of heat. However, if we consider the storage of fuel, that is, converting the calorific value unit into million joules/liter, hydrogen fuel does not seem to be so efficient: on the one hand, at normal temperature and pressure, hydrogen fuel will exist in gaseous state, and hydrogen fuel at this time cannot be compared with any liquid fuel; on the other hand, even if hydrogen is compressed into liquid hydrogen by low temperature and high pressure, hydrogen fuel can only generate 10 million joules of heat per liter of liquid hydrogen due to its extremely low density, while gasoline and kerosene at this time are the masters with calorific values of 32 and 35 million joules/liter. In other words, if the same volume of fuel tank is changed to liquid hydrogen instead of aviation kerosene, the energy generated is only 1/3 of the original.

It should also be noted that in order to store liquid hydrogen in a high-pressure and low-temperature state, low-temperature-resistant and high-strength containers are required. The most important thing is that these containers must be made into cylindrical or spherical shapes. Therefore, when multiple containers are placed, it will inevitably cause a waste of space. In comparison, gasoline or kerosene can be stored in tanks of any shape, which can be placed in places such as wings, and the requirements for the strength of the tanks are much lower.

It is precisely because of the "inefficiency" of hydrogen fuel in terms of volume calorific value that the Tu-155 aircraft of that year converted the rear 1/3 of the cabin into a liquid hydrogen fuel tank in order to load as much hydrogen fuel as possible. The seats in the main part of the cabin were also removed and replaced with densely packed small-volume hydrogen fuel tanks. Such an aircraft obviously could not meet the passenger requirements.

Therefore, in manufacturing hydrogen-powered aircraft, replacing the power system is only the first step - even the simplest step. How to re-plan the structural layout of the entire aircraft based on the characteristics and needs of hydrogen fuel storage is the most headache for aircraft manufacturers.

This fuel is dangerous and too active.

As mentioned above, in order to store as much hydrogen fuel as possible, it is necessary to store hydrogen fuel in liquid form through high pressure and low temperature. However, how to smoothly inject hydrogen fuel into the engine combustion chamber and effectively control the injection speed is a difficult problem.

In fact, this is conceivable: during the flow of liquid hydrogen in the pipeline, the pressure and temperature of the environment are changing rapidly, making the gasification process of liquid hydrogen difficult to predict. In addition, the existing aviation engine fuel control system almost does not consider low temperature and fuel gasification. In particular, hydrogen is the gas with the lowest density in nature. It is highly compressible. The adjustment of the valve in the engine fuel pipeline has obvious damping and hysteresis effects, which makes it extremely difficult to measure and adjust the dynamic high-precision hydrogen.

Therefore, don’t look at aviation kerosene as a fuel, liquid hydrogen is also a fuel, but it is actually very difficult to effectively control the mixing and combustion of hydrogen fuel and air. In addition, hydrogen fuel is too active in terms of chemical properties, which is reflected in two aspects: on the one hand, hydrogen and air can be ignited and explode almost as long as they are mixed (when the concentration of hydrogen in the air is in the range of 4.0%-75.6%); on the other hand, when hydrogen burns, the flame transmission speed is too fast, almost 6 times that of aviation kerosene, and it is very easy to "backfire". Therefore, when hydrogen fuel is supplied to the engine, it is often not possible to pre-mix the hydrogen fuel (that is, hydrogen and air are mixed in a specific ratio in advance and then sent into the combustion chamber for combustion), otherwise once the flame burns upstream along the air supply pipeline, it will cause a safety accident.

This fuel seems to be environmentally friendly, but it is not environmentally friendly

As mentioned at the beginning of this article, hydrogen fuel will only produce water when it reacts with oxygen, so this is regarded as the most environmentally friendly fuel, which is also the fundamental reason why hydrogen fuel is currently regarded as a green fuel.

However, this statement is only half right in actual engines. Because in the engine, hydrogen is mixed with air and burned, and in addition to oxygen, the air also contains a large amount of nitrogen. Even though nitrogen itself is a relatively stable gas, it will react with oxygen at high temperatures to produce nitrogen oxides (NOx), and the higher the combustion temperature, the greater the amount of NOx generated.

Compared with the flame of aviation kerosene, the flame temperature of hydrogen combustion is 150 degrees Celsius higher, and the production of NOx is almost exponential. So from the perspective of carbon emissions, hydrogen fuel perfectly achieves "zero emissions" and is an extremely environmentally friendly product, but from the perspective of NOx, hydrogen fuel cannot meet the standards, and can even be said to be "severely polluting." More importantly, in the existing low-emission technology of aircraft engines, "lean oil premixed combustion technology" is often used to prevent the generation of NOx. In layman’s terms, it is to mix air and fuel together in advance and then ignite them, so as to "dilute" the fuel as much as possible and avoid excessive flame temperature. However, as mentioned above, hydrogen cannot be pre-mixed to prevent "backfire", which makes the existing low-emission technology useless and needs to start from scratch.

In addition, although hydrogen fuel itself burns relatively environmentally friendly, the process of making hydrogen may not be so. At the same time, the high cost of hydrogen production also seems to be particularly wasteful.

So, ideals are ideals after all. At least in the aviation industry, the development of hydrogen-powered aircraft can be said to have a bumpy road ahead due to the various problems of hydrogen fuel itself.

Where is the future?

Traditional aviation giants’ "positional warfare" Although each traditional aircraft manufacturer has a plan to develop hydrogen-powered aircraft, most of them are small aircraft based on hydrogen fuel cell technology. Especially the two giants of civil aircraft manufacturers: Boeing and Airbus. Only Airbus has come up with the ZEROe hydrogen-powered concept aircraft, proposing to achieve commercial operation before 2035; while Boeing seems indifferent, and even some interviews with Boeing executives reveal that this traditional aircraft manufacturing giant does not regard hydrogen-powered aircraft as a major strategic direction.

Of course, the caution of the aircraft manufacturing giant is understandable. Because the replacement cycle of commercial aircraft is about 50 years, once the wrong direction is taken and the wrong technology tree is selected, half a century of strategic opportunities will be lost directly, so it is naturally cautious.

In contrast, aircraft engine manufacturers appear to be slightly more proactive: CFM launched the RISE program in 2021 to develop hydrogen fuel engine technology, and in 2022, it worked with Airbus and GE to carry out a hydrogen demonstration project to conduct ground and flight tests on hydrogen fuel engines; Pratt & Whitney received support from the U.S. Department of Energy in February 2022 and launched the Hydrogen-Steam Injection, Intercooled Turbine Engine (HVSIITE) project, which will use liquid hydrogen fuel and water vapor recovery to achieve zero carbon emissions in flight; Rolls-Royce has already conducted a hydrogen fuel drive test on an AE-2100A engine in December 2022. As the saying goes, "power comes first", it is reasonable for aircraft engine manufacturers to take the lead in testing the waters.

The "Guerrilla Warfare" of Emerging Aviation Enterprises

For large aviation companies, if they only focus on small aircraft powered by hydrogen fuel cells, then even if they succeed in the end, the economic profits they get can be said to be tasteless and useless. However, for some emerging aviation companies, using fuel cell technology with a low threshold to build small aircraft that meet market demand is a way to squeeze into the aviation industry and get a share of the pie.

In fact, according to statistical analysis, there are 300 new energy aircraft projects underway worldwide (not only hydrogen aircraft), of which 60% are invested by startups and independent individuals, and more than 90% of the projects aim to develop aircraft with less than 10 seats. Therefore, small aircraft have always been a hot area for emerging aviation companies. Although it is difficult to expect these companies with limited funds to break through key hydrogen energy technologies, attracting a large number of scientific researchers to join the research and increase the demand for hydrogen fuel can effectively absorb talents and reduce the production cost of hydrogen fuel, which is crucial for the healthy growth of the hydrogen aircraft industry.

“Dual guarantee” of regulatory authorities and infrastructure

Hydrogen aircraft involve multiple industries such as energy, manufacturing, transportation, and infrastructure. Moreover, if we observe carefully, no industry can be controlled by one or two enterprises. Therefore, if we want hydrogen aircraft to land smoothly, we must rely on top-level planning, which involves many issues of regulatory authorities and infrastructure.

From the perspective of regulatory agencies, hydrogen aircraft have obvious differences from traditional fuel aircraft due to their overall aircraft structure, power system and fuel storage method. Therefore, only after reaching the same or higher airworthiness safety standards can they be truly put into commercial operation. Here is a simple example: when ordinary metals store liquid hydrogen, a phenomenon called “hydrogen embrittlement” will occur, that is, as hydrogen penetrates into the metal, it will inevitably cause the metal’s toughness to decrease and it is very easy to crack. For enterprises, whether aircraft manufacturers or airport operators, whether out of subjectivity or ignorance, they tend to ignore these potential dangers to reduce costs. Therefore, regulatory authorities must formulate detailed regulations around the potential dangers of hydrogen-powered aircraft. While restricting enterprises that want to let go of themselves from engaging in dangerous behaviors, they cannot set too high a threshold to restrict emerging enterprises from injecting new vitality. This tests the wisdom of managers.

In addition to supervision, there is another problem, which is infrastructure, including hydrogen fuel storage facilities, hydrogen fuel cheap production facilities, etc. At present, hydrogen fuel has a certain degree of application and technical foundation in the energy industry and aerospace industry. The underlying common technology can theoretically be interoperable with the aviation industry, but it is not something that a few companies can do to truly transform these technologies into infrastructure. Therefore, the state has stepped forward to support a group of professional enterprises with development potential, improve infrastructure, and cultivate innovation chains and industrial chains for hydrogen-powered aviation. While integrating domestic hydrogen energy research and development resources and industrial resources, it can greatly accelerate the development of hydrogen-powered aircraft.

Epilogue

Environmental protection is one of the major themes of the 21st century, which creates a background of "having to succeed" for hydrogen-powered aircraft, but the world is materialistic, and good vision will not be an excuse for laziness in technology. Seeing the advantages of hydrogen fuel, but also being able to solve the problems of hydrogen fuel, and down-to-earthly realizing "zero-emission aviation" may be the problem faced by the entire aviation industry.

However, fortunately, every technological innovation is an opportunity for emerging countries and emerging companies. Because hydrogen-powered aircraft are not something that traditional aviation companies can solve with existing technologies, at this point in time, everyone - every country and every company, is almost standing at the same starting line, and whoever can seize this opportunity, solve existing problems, and complete technological evolution first will be the winner of the next stage.

The road ahead is certainly bumpy, but we should certainly see the opportunities. I wonder if the aviation industry can break a new path with its own efforts and technological innovation like new energy vehicles?

Let’s wait and see.