The logistics equipment of the U.S. military has developed into a relatively complete system according to the war level, which includes three major types of logistics equipment: strategic delivery, campaign support and tactical support. The U.S. military attaches great importance to the construction of the engineering equipment system, and has developed and deployed different types of engineering equipment according to the different combat needs of different troops. The "U.S. Navy Planning Guide" points out that the forward-deployed "Seabee" troops need tailor-made engineering equipment to ensure various joint operations. To this end, the U.S. Navy has formulated a long-term plan to adjust the budget table of all Seabee forces: first, to fill the existing gaps and replace aging tools and equipment that are no longer compatible; then, in the next few years, the Seabees will be equipped with modern and reusable tactical vehicles, construction and maintenance equipment, communication equipment, infantry equipment and field support equipment. At present, the engineering equipment of the Seabee force has the characteristics of long-range transportation and delivery, one machine with comprehensive multi-functional long-range precision operations, emphasis on self-protection, and adaptation to multi-dimensional perception.

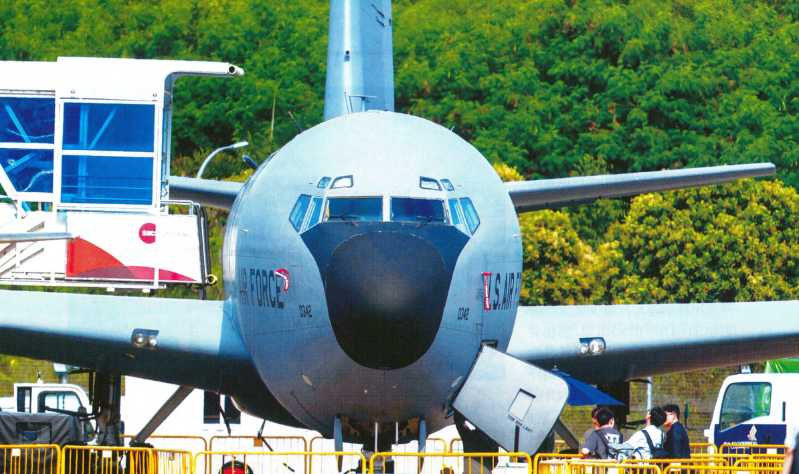

The U.S. Navy believes that in the logistics equipment support of the 21st century, the speed of support is more important than the number of support resources. To this end, in order to cope with various emergencies, the Seabees attach great importance to the rapid loading/unloading and long-range transportation and delivery of engineering equipment. All types of engineering equipment in service can be transported by supply ships or by C-130 The transport aircraft can be quickly deployed by air transport/airdrop.

The mobile construction battalion is the main force of the "Seabee" force. Each construction battalion has about 600 people and is mainly responsible for the construction of expeditionary military engineering facilities and engineering support operations. The main equipment of the "Seabee" includes crawler excavators, wheeled excavators, crawler loaders, wheel loaders, skid loaders, backhoe loaders, crawler bulldozers, wheel bulldozers, graders, telescopic boom loaders, vehicle-mounted pump pavers, tire rollers, etc. They mostly use CAT, DEERE, JCB The medium and large equipment of the company. Since most of them are medium and large equipment with complex structures, operators must undergo professional training, understand the mechanical performance and structure, master maintenance knowledge, and be able to master the performance of the model and the operating essentials and safety matters. They need to have the qualifications of level 3 to level 1 equipment operators and be confirmed as qualified by the relevant departments before they can operate alone. It is mainly used in: forward base/camp construction; fortification construction; main supply road construction/repair; bridge construction; expeditionary airport/port construction; ammunition supply point construction, prisoner of war camp construction; public facility construction/maintenance; airport runway/port terminal damage repair; post-disaster recovery operations, etc.

Excavator

Excavator is an earth-moving machine that uses a bucket to dig materials above or below the bearing surface and loads them into transport vehicles or unloads them to the stockpile yard. The excavators equipped by the "Seabee" troops are mostly crawler-type, and the main excavated materials include soil, mud, sand and rocks, etc., to provide site guarantees for the construction of facilities

Loader

In road construction, especially in high-grade road construction, loaders are used for filling and excavation of roadbed projects, asphalt mixture and cement concrete material yards, and other operations. In addition, they can also carry out operations such as pushing soil, leveling the ground, and towing other machinery. Because loaders have the advantages of fast operation speed, high efficiency, good mobility, and easy operation, they have become one of the main types of earthwork construction in the engineering construction of the Seabees, and are widely used in the Seabees.

The bucket capacity of the CAT 963K crawler loader equipped by the Seabees is 2.5 cubic meters, which can perform a variety of tasks, such as seven-ground cleaning, excavation, leveling, and truck loading slope operations. Compared with wheel loaders, crawler loaders can provide lower ground pressure and better traction. They can work quickly and for longer periods of time on soft ground conditions. They can also perform landfill or enter ship cabins.

The CAT 426F2 excavator loader adopts a high-level cab, provides an air suspension seat, spacious legroom, good vision, and an ergonomically designed joystick that is easy to operate and smooth. It can not only perform excavation operations, but also loading operations, making it very suitable for multi-functional operations on islands. In terms of actual use, this type of machine can also expand many application functions. For example, on April 17, 2018, when the "Seabee" was operating on Carlson Island near Kwajalein Island, it used the CAT 426F2 excavator loader to unload 8 fresh water storage tanks to Carlson Island for the construction of a fresh water storage project. After the project was completed, the island had more than 12,000 gallons (about 45,400 liters) of fresh water, which is a considerable amount for about 50 people on the island. The design of this project not only has a lasting impact on Carlson Island, but also serves as a freshwater reserve base for other islands in the Marshall Islands. When it comes to supporting the Marine Corps, the Seabees are also the best choice. For example, on July 20, 2022, the Seabees of the 1st Mobile Construction Battalion in Mississippi drove a CAT 426F2 excavator loader to perform the "Turning Point Operation" exercise with the 273rd Support Squadron of the US Marine Corps. The CAT 986K wheel loader is durable, highly reliable, high-performance, low fuel consumption, easy to maintain, and has a long life cycle. It can also cope with the most demanding loading conditions. This type of machine is usually used to load rocks, which are then crushed by a crusher to produce aggregates (granular materials that act as skeletons and fillers in concrete and mortar). It can be used for tasks such as airport and port damage repair. It is usually to cooperate with the combat operations of the US Navy fleet, carry out mobile construction tasks, or implement humanitarian assistance and strengthen theater security cooperation.

In March 2019, the U.S. Navy conducted an airfield damage repair (ExRADR) exercise at Vandenberg Air Force Base in California. The exercise was designed to test the ability of the "Seabee" force to repair the runway and provide continuous support for the operations of the Navy and Marine Corps. During the exercise, officers and soldiers of the 5th Mobile Construction Battalion used a CAT 246D3 loader to remove runway debris.

Vehicle-mounted concrete pump

Vehicle-mounted concrete pumps are concrete pumps installed on the chassis of motor vehicles, mainly used to complete the concrete pouring of buildings, roads, bridges, airports and tunnels. The Schwing HBC10040V vehicle-mounted concrete pump equipped by the "Seabee" not only has the advantages of convenient movement and flexibility of the pump truck, but also inherits the advantages of high pumping pressure of concrete trailer pumps, suitable for small and high-rise concrete pumping, and low cost. It can meet the construction needs of high-rise buildings, bridges, tunnels, factories, power stations, etc. that require high-pressure, long-distance pumping of high-strength concrete. The maximum pumping height can reach 600 meters, and the maximum horizontal pumping distance can reach 2,400 meters.

In the operations carried out by the US Navy, the vehicle-mounted concrete pump can also be used to repair airport runways. The operator pours the wet concrete on the crater and smoothes it. The repair is completed after it dries. In order to improve the training effect, the "Seabee" also launched the "Damaged Airport Repair" (Airfield Damage Repair.ADR) training platform. During the training, 8 operators are used as a task group to repair the damage, and there is also a special ADR course training. The platform can improve the interoperability of the entire fleet and mobile construction battalions, underwater construction teams and explosive ordnance disposal units. It will enable the "Seabee" operating units to reduce the time required for ADR and reduce the demand for logistics support.

Paving machine

The paver is a construction equipment used for paving various materials on the base and surface layers of high-grade roads. It consists of various subsystems that cooperate with each other to complete the paving work, mainly including the walking system, hydraulic system, material distribution system, etc. The main paving materials are crushed stone and asphalt concrete.

In June 2022, the 11th Mobile Construction Battalion of the "Seabee" repaired Runway 04 at Truax Airport, Corpus Christi Naval Air Station. The battalion sent a 14-member task force to use the CAT APSSSF crawler paver to lay a 3-inch (7.62 cm) thick base asphalt runway to support the training of naval flight cadets. The CAT APS5SF is a medium-sized rubber crawler paver suitable for asphalt paving on roads. It has a high driving speed, excellent traction and maneuverability. The automatic filling feeding system allows the conveyor and the spiral feeder to work alternately until the mixture height reaches the sensor set point. This unique system eliminates manual start-up and continuous human monitoring, achieving more stable performance.

Crusher

Crusher is a crushing machine that breaks rocks into small particles by squeezing and bending. The crushers equipped by the "Seabee" troops are mostly "Eagle" mobile jaw crushers from the American EAGLE company. It consists of two jaw plates, the moving jaw and the static jaw, to form a crushing chamber. It simulates the movement of the two jaws of animals to complete the rock crushing operation, and has an advanced human-machine system that can be operated by a third-level equipment operator.

In July 2021, the U.S. Air Force planned to repair the road at Anderson Base in Guam, and the required stones were blasted near the base. However, at this time, the crushed stone of the 554th "Red Horse" Engineer Squadron of the U.S. Air Force could not be used for some reason, and the on-site materials could not produce aggregates, so they had to ask the "Seabee" for help. "The 11th Mobile Construction Battalion of the Seabees dispatched a crusher and five operators to the site. First, the crusher parts were transported to the quarry, and then assembled on site. 300 cubic meters of stone were crushed and then transported to Anderson Base to assist the "Red Horse" squadron in the preparation of repair materials. During this period, the "Red Horse" squadron personnel also practiced assembling and disassembling crushers with the "Seabee" troops to improve their maintenance skills. The rock crushing task is an extremely important task for the "Seabee" troops, because it is the basic work of the US military’s global "sea deployment engineering construction. The "Seabees" attach great importance to the efficiency of this work and the delivery speed of engineering equipment.

Bulldozer

Bulldozers are earthmoving engineering machinery that can dig, transport and discard rock and soil. The "Seabee" troops are mainly equipped with CAT’s Bulldozers of models such as D4, D5K, and D6K are mainly used for land leveling before construction, such as for construction, leveling spoil dumps, piling up scattered ore and rock, leveling work and construction sites, etc. The tasks performed by the "Seabee" using bulldozers also include: foundation leveling before building facilities, site cleaning, temporary paving of helicopter landing sites, etc.

Forklift

Forklift is a machine evolved from loader. The British JCB company first proposed the concept of telescopic forklift in 1973. It is a multi-purpose lifting and handling equipment that combines stability and high efficiency. It can lift and raise items and is suitable for the handling needs of various materials. The "Seabee" is mainly equipped with JCB 510 telescopic forklift, CAT TH408D and CAT DP30 Type forklift. The main use environment includes: heavy object (including container) handling, hazardous material handling, high-rise building material lifting, etc.

Crane

Crane is a multi-action lifting machine that can lift and transport heavy objects vertically and horizontally within a certain range. The "Seabee" force is mainly equipped with LINK-BELT HTC-8640 S wheeled hydraulic truck crane, which relies on an internal hydraulic system to lift heavy objects. The lifting mechanism is installed on a wheeled chassis, making it more maneuverable on the job site. Hydraulic truck cranes are usually equipped with an enclosed cab for the operator, mounted on a steel base, and a long telescopic arm that can be articulated or fixed, depending on the specific construction needs of each project. In addition, the crane can also be used for loading/unloading combat equipment such as combat vehicles, equipment storage boxes, etc.

Grader

Grader is the main machine used for shaping and leveling operations in earthwork engineering. It is widely used in large-scale ground leveling operations such as roads and airports. The reason why it has a wide range of auxiliary operation capabilities is that its scraper can be adjusted 6° along the vertical axis. In roadbed construction, the grader can provide sufficient strength and stability for the roadbed. The main methods in roadbed construction are leveling operations, brushing slope operations, and filling embankments.

The "Seabee" is mainly equipped with Volvo G990 graders and CAT 18M3 graders. When building large airports or repairing large-scale leveling facilities, graders can be used to level fillers to improve the basic road surface. Compared with bulldozers, they have a large area of action and high leveling efficiency. For large areas, the operating cost is low and the fuel economy is high.

Compacting machinery

Compacting machinery is an earth-moving machinery that uses mechanical force to compact the filling layers of soil, gravel, etc., and is widely used in foundations, roads, airports, dams and other projects. The "Seabee" is mainly equipped with the CAT CS54B soil compactor, which adopts a vibrating design. On the basis of the static compactor, an exciter is added to rearrange the material particles in resonance and make them dense. It is characterized by high vibration frequency and good compaction effect on loose soil and rocks with low cohesion, such as sand, gravel, etc. This is also the most easily available construction material for the "Seabee" in the mission environment.