In recent years, Iran’s ballistic missile and launch vehicle technology has developed rapidly, especially new solid-fuel ballistic missiles have been continuously launched and their performance has been continuously improved. The outside world believes that Iran has established a relatively comprehensive solid-fuel missile research and development and production system, and will comprehensively develop solid-fuel ballistic missiles with better performance like North Korea.

Development history

Solid-fuel missiles are faster, more reliable and smaller than liquid-fuel missiles. Due to the high technical threshold, although Iran started solid-fuel missiles earlier, its achievements are far less significant than those of liquid-fuel missiles.

From "Frog" to "Conqueror"

In the 1970s, Iran and Israel formulated the "Oil for Weapons" plan, and Iran’s missile research and development plan began at that time. In 1980, after the outbreak of the Iran-Iraq War, Iraq used ballistic missiles to attack Iran. Iran, which suffered a lot, realized that it must realize the localization of ballistic missiles. Through the use of liquid fuel missiles in the Iran-Iraq War, Iran found that liquid fuel missiles have inherent deficiencies, and there are problems with the research and development of liquid fuel storage technology and subsequent reliability. Therefore, in the early stage of ballistic missile development, Iran developed solid fuel missiles while developing liquid missiles. During this period, the Iraqi army’s "Frog" 7A uncontrolled rocket had left a deep impression on the Iranian army, so Iran first imitated the "Frog" 7A, which is the famous "Earthquake" series of rockets. The performance of this series of rockets is comparable to the "Moon" M tactical missile system equipped by the Soviet Union in 1964. Due to the range of less than 90 kilometers and low accuracy, these rockets are mainly used to strike large cities close to the front line. Later, Iran referred to the imported "Sam" 2 missile control system and "Scud missile guidance system, and finally developed Iran’s first solid fuel ballistic missile "Conqueror" 101, which expanded the range to more than 200 kilometers. The development of this missile began in 1997. It was officially unveiled in 2001. Its main function is to make up for the lack of accuracy of the "Earthquake" rocket and fill the firepower gap between the "Meteor" 1 missile and artillery. Later, the "Conqueror" 110 was developed. The 101 and 110 in the name refer to the diameter of the engine nozzle. Through the development of these two types of missiles, Iran has basically solved the problem of raw materials necessary for the production of solid rocket propellants. In January 2000, Iran’s industrial sector SBIG announced that it had achieved self-sufficiency in hydroxybutyric acid resin (HTPB), aluminum powder and potassium chloride.

"Mudstone" Out of nowhere

After the solid fuel technology has gradually achieved results, Iran began to combine it with large multi-stage liquid fuel missile technology such as "Meteor" 3 to develop solid fuel missiles with longer range. In August 2005, the Iranian government claimed that it had successfully developed solid fuel technology for ballistic missiles. Iranian Defense Minister Shamkhani said, "Iran has fully mastered the solid fuel technology for producing missiles and has taken an important step forward." At this time, Iran was developing a solid fuel missile called "Ashura". This plan did not go smoothly, but it was eventually upgraded to "Mudstone" 110 and successfully tested in November 2008. Its extended-range version was launched in In 2009, the tests were also successful. In May 2009, Iranian TV broadcast the launch footage of this type of missile for the first time, calling it the "Mudstone" 2 missile, and claiming that its range reached 2,000 kilometers. The missile uses a new type of composite solid propellant, has the characteristics of high speed and high precision, and can use the land-mobile transport-erection-launch device of the "Meteor" series of liquid-fuel missiles. Since Iran’s previous solid-fuel missiles were all single-stage, the two-stage rocket technology used by the "Mudstone" 2 is a great improvement for Iran. It has a large design margin, can further increase the range, and has the potential to develop into a long-range missile. This indicates that Iran’s missile development technology has made a great breakthrough and provided conditions for the formation of a comprehensive and effective ballistic missile combat deterrence. However, since then, the "Mudstone" missile has only appeared in military parades, and reports on test flights have gradually decreased. The outside world estimates that Iran’s solid missile development plan has encountered a technical bottleneck, and it may be due to A major accident in November 2011 caused a long-term stagnation of related work. In this accident, not only was Iran’s solid rocket engine test facility destroyed, but also many solid fuel missile technology experts died, which caused fatal damage to Iran’s missile development.

The increasingly accurate "Conqueror"

After the development of large solid fuel missiles was frustrated, Iran adjusted its missile development route. Medium and long-range large missiles are mainly liquid fuel, while solid fuel missiles are mainly improved in terms of strike accuracy and reliability. In 2011, in response to the threat of the United States to blockade the Persian Gulf, Iran quickly developed the "Persian Gulf" anti-ship ballistic missile with optoelectronic guidance and the ability to strike maritime targets based on the "Conqueror" 110. The range of the missile has been extended from the original 200 kilometers to 250 kilometers. In August 2012, the fourth-generation "Conqueror" 110, although the range remains unchanged, uses a more accurate guidance system. In August 2015, Iran exhibited the Conqueror 313 missile for the first time at its "Defense Industry Day" ceremony. Compared with previous missiles, the missile has redesigned its tail, added guidance components, and reduced its load carrying capacity. It not only inherits high accuracy, but also has a range of 500 kilometers. Although the Conqueror 313 and the Conqueror 110 have similar appearance and structure, they have greatly increased the missile’s range by improving the flight characteristics of the missile to obtain greater lift, using a larger thrust and more effective propulsion system, reducing the weight of the payload, and using lighter materials to reduce the weight of the missile body. The successful development and deployment of the Conqueror 313 missile has further strengthened Iran’s conventional short-range precision strike capability and consolidated its position as a military power in the Middle East. This type of missile performed well in the attack on the U.S. Assad Airport in Syria in January 2020, demonstrating Iran’s high level of precision guidance technology.

The thin hair after "Thunder"

After 2016, Iran’s solid-fuel missiles continued to develop in the direction of long-range precision and made important progress. In September 2016, Iran first exhibited a solid-fuel missile called "Zulfiqar" at a military parade, and then began mass production, claiming that the missile had a range of up to 700 kilometers, enough to deter Israel. From the picture, it still belongs to the "Conqueror" series. Due to the small size of the warhead, according to the empirical formula for converting the missile range to the warhead weight, if its overall technical level is the same as the "Persian Gulf" missile in 2011, the warhead weight may be reduced to 250 kilograms. From the target shooting video of the missile released by Iran, it has the ability of precision guidance, thus ensuring that it still has sufficient power at such a range. On this basis, Iran developed a solid-fuel anti-ship ballistic missile named "Hormuz" 2, and successfully tested it in March 2017, indicating that Iran’s ballistic missile guidance technology has reached a new level. While the guidance technology has gradually improved and become reliable, Iran has also focused on the development of solid-fuel rocket engines and applied them to the new generation of missiles. In February 2020, the Iranian military officially unveiled the new tactical ballistic missile "Thunder" 500 (Raad-500). It uses a new engine design and new materials, with a maximum range of 500 kilometers, and weighs only half of the "Conqueror" series of missiles. The thrust-to-weight ratio has increased significantly, and the strike accuracy has also improved qualitatively.

The emergence of a series of new solid-fuel missiles indicates that Iran’s campaign tactical ballistic missiles have begun to fully realize solid fuel. On August 13, 2017, the Iranian parliament passed a bill to increase the budget of more than 500 million US dollars for Iran’s missile system research and development and other projects. With the increase in missile range and payload capacity, solid-fuel missiles will fully replace existing "Meteor" 1 and other missiles of the same level. At the same time, the new solid-fuel missile technology will also be applied to the development of military aerospace and medium- and long-range missiles.

Main technical projects of Iran’s solid-fuel rockets

Currently, Iran’s solid-fuel missile/rocket technology is mainly used in projects such as the "Conqueror" series of short-range missiles, the "Mudstone" series of medium-range missiles and the final stage rockets used in space launch vehicles.

The "Conqueror" short-range missile

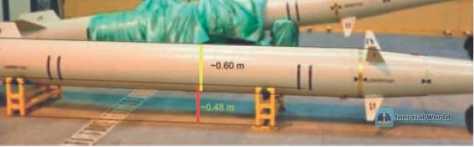

In 1997, Iran’s Bahari Industrial Group began to develop the "Conqueror" short-range missile based on the "Earthquake" 2, a copy of the "Frog" rocket. In September 2002, the first generation of the "Conqueror" 110 missile was successfully developed and mass-produced, with a range of 200 kilometers. From 2004 to 2016, Iran developed and equipped four generations of "Conqueror" missiles, with a range of 300-500 kilometers, and the dimensions and weight remained basically unchanged, that is, the missile length is 8.86 meters, the diameter is 0.61 meters, the launch mass is 3.45 tons, and the payload is 450-650 kilograms. They are all single-stage solid, road-mobile ballistic missiles. "Conqueror" 313 is an improved or extended-range version of the fourth-generation "Conqueror". Its latest "Zulfiqar" solid-fuel missile should also be a development of the "Conqueror" series of missiles. The range has been increased to 700 kilometers, indicating that its engine and fuel technology have reached a new level.

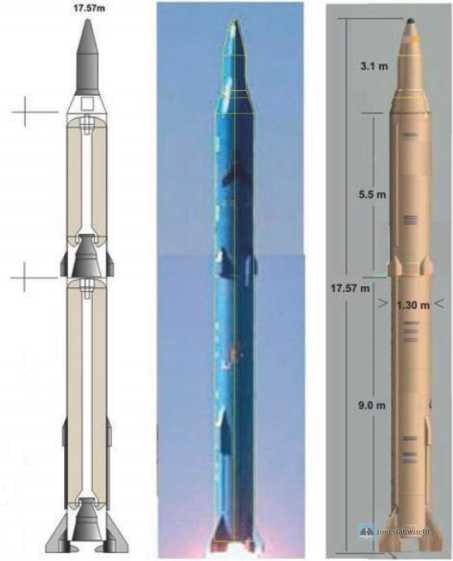

’Mudstone’ medium-range missile

’Mudstone-2 is a two-stage surface-to-surface missile independently developed by Iran, which uses solid fuel completely and has a range of more than 2,000 kilometers. The total weight of the missile is 26 tons: 19 meters long, about 1.4 meters in diameter, and the warhead weighs about 1 ton. The missile has a three-conical warhead similar to the Meteor-3, and the guidance system is located in the second stage. Compared with the Meteor-3, the performance of the Mudstone-2 has been greatly improved. This is mainly manifested in: first, the responsiveness has been improved. The erection time of the former on the launcher is several hours, while the latter is greatly shortened to 30 points. The second is the improved survivability. Although the former can be mobile on the road, due to the use of liquid propellant, the reliability is poor, which affects the mobility. The latter uses solid propellant, does not need to be refilled in advance, and has high reliability, good mobility, and is convenient for combat use. The third is the improved hit accuracy. The former has a maximum hit accuracy of 1,000 meters, and the latter is estimated to have a hit accuracy of up to 350 meters. If the "Mudstone" 2 is launched from the western region of Iran, it can bring NATO’s military bases deployed in Greece and Turkey and even the NATO Southern European Command in Naples, Italy into the strike range.

"Thunder" short-range missile

In February 2020, Iran announced the "Thunder" 500 tactical ballistic missile, which has a great technological leap compared with the previous "Conqueror" series missiles of the same type, and its engine performance and efficiency have been greatly improved. The missile is 8.4 meters long, with a body of 5.4 meters and a warhead of 3 meters. Its engine and body are significantly smaller than those of the Conqueror, but its warhead is larger than that of the Conqueror, which can effectively increase the mass and volume of the warhead. The missile warhead is equipped with four triangular control wings at the rear, and the tail of the body is equipped with four truncated right-angled triangular tail wings, which shows that the Thunder 500 has better air body and rocket power control capabilities. In addition, the engine shell is made of carbon fiber material, which reduces the mass of the whole missile from 3.45 tons of the Conqueror 110 to 1.6 tons, but the range has increased by more than 200 kilometers, reaching an astonishing 500 kilometers. The appearance of this type of missile shows that Iran’s solid fuel missile technology has reached a new level.

"Symon" launch vehicle stage From the perspective of the development of Iran’s space launch vehicle technology, the latest "Phoenix" rocket is equipped with the saman-1 solid vector engine developed from the "Conqueror" series of missiles. The engine of this stage is 1.25 meters high and 1.5 meters in diameter. It is designed as an integrated unit with the satellite payload, and part of it is in the fairing. This stage uses solid fuel, which greatly increases the thrust of the rocket while reducing the volume and mass. In particular, its vector nozzle design enables it to control the satellite payload to enter orbit accurately. Brigadier General Hajizadeh, head of Iran’s aerospace industry, said that the currently developed adjustable nozzle technology can be applied to the development of spacecraft, satellite carriers, anti-tank missiles and air defense missiles, especially the control technology of solid fuel rocket engines outside the atmosphere can greatly improve Iran’s aerospace launch and control technology.

Technical features of Iran’s solid-fuel rockets/missiles

Generally, solid-fuel missiles are smaller in volume than liquids, so they are easy to transport and operate, and the fuel and missile are integrated, which greatly shortens the launch preparation time. This is the main reason why Iran actively pursues solid-fuel missiles. Under strict sanctions from the outside world, Iran continues to explore the development of this missile, which makes its technology show some unique characteristics.

Engine design level

The nozzle of the solid-fuel missile engine is mainly used to discharge supersonic gas and generate thrust. There is a gas rudder outside the nozzle assembly to control the flight posture of the missile. Under the control of the ignition command, the ignition device releases the safety insurance and ignites the pyrotechnic powder, generating a high-temperature and high-pressure flame to ignite the propellant in the shell. From the engine of Iran’s most powerful solid-fuel missile "Mudstone" 2, one of the differences between its second stage and the first stage is the design of the nozzle. The gas expansion rate of the second stage nozzle is greater than that of the first stage engine. This is because the first-stage engine started on the ground often uses a shorter nozzle, while the second stage uses a longer nozzle to increase the expansion ratio to improve the engine efficiency. In order to allow the propellant gas flow to fully expand so that more chemical energy can be converted into kinetic energy, the designer will lengthen the engine nozzle. But in this way, the overall length of the rocket is increased. Too long and thin rockets are prone to induce vibration and reduce stability. The former will cause the rocket to break, and the latter will make the rocket difficult to control and crash. Because of this, the length-to-diameter ratio of the "Mudstone" 2 missile is too large, which limits its further improvement in performance. In addition, before the appearance of the "Thunder" missile, all known Iranian solid-fuel missiles still used the gas rudder control technology used by liquid-fuel missiles. Although this technology has a low threshold, the control accuracy and efficiency are obviously low. At present, although Iran may have mastered the engine vector nozzle technology through the "Thunder" missile, it should not have been applied to large solid-fuel engines.

New materials are actively applied

In 2005, Iran illegally imported metal-ceramic composite materials from India and other countries for use as heat-resistant materials for rocket engines. In August 2011, Iranian Defense Minister Vahidi announced that Iran had overcome the difficulties in the production of carbon fiber composite materials and "will eliminate the weak links in the production of Iran’s modern military equipment." Carbon fiber composite materials can flexibly design the fiber layer and laying direction according to the structural requirements of solid rocket engines. Missile bodies or engines made of carbon fiber composite materials have high specific strength, specific stiffness, and excellent properties such as vibration and impact resistance, fatigue resistance, and corrosion resistance, while greatly reducing the weight of the structure. For example, the engine shell of the "Mudstone" 2 missile is also the rocket combustion chamber, which is the place where the propellant charge is stored and burned. The temperature of the gas generated by the combustion chamber column is as high as 3000~3900K and the pressure is 3~20 MPa. General metal materials cannot meet this requirement. The shell of the Mudstone 2 engine is made of high-strength steel, and the inner wall of the combustion chamber is made of special high-temperature resistant materials, which can not only withstand the effects of high-temperature and high-pressure gas, but also withstand the aerodynamic pressure and various mechanical stresses during flight as a structural part. The Conqueror 313 and Thunder missiles have already used new materials for key components such as missile engine shells, nozzle linings and gas rudders. With the increase in missile range, it is believed that the application of new materials will be further expanded in components such as missile reentry warheads.

Solid fuel production technology is improving rapidly

In January 2000, Iran’s Shahid Bekre Industrial Group announced that the raw materials for the production of solid rocket engine propellants have achieved self-sufficiency. Judging from the situation of the Mudstone 2 and Conqueror series missiles, they mainly use HTPB composite propellants, the main components of which are iron perchlorate with a high oxygen content and terminal polybutadiene, etc. Aluminum powder is also added as a combustion aid to increase energy density. The main raw materials of these materials are butadiene resin, aluminum powder and potassium chloride. Iran currently uses the casting process for solid fuel processing, which is to spray the coating layer (usually the same system as the propellant adhesive) after the shell and the insulation layer are cured, and then the mixture of the propellant formula is placed in the shell with the core mold, cured under vacuum conditions, and then the core mold is removed. At this time, the grain is tightly bonded to the shell. This process is relatively simple and suitable for manufacturing grains of various sizes. It has good comprehensive performance, a wide operating temperature range, high energy, and good mechanical properties. Overall, Iran’s solid rocket engine propellant production has reached the international third-generation level and is currently moving towards the fourth-generation level.

General technology of integrated liquid fuel missiles

Like other emerging missile countries such as North Korea, Iran’s missile technology also started from the development of liquid missiles and led the direction of national missile technology. In order to rapidly develop solid-fuel missiles, Iran has actively applied the guidance and control technologies of liquid-fuel missiles to solid-fuel missiles in different series of missiles. In November 2008, Iran’s Tehran Alen State Television reported that the "Mudstone" missile has a tri-conical warhead similar to the "Meteor" 3 liquid-fuel missile. This may be a brand-new re-entry vehicle design to adapt to the new warhead that Iran has already studied, which can resist the missile defense systems of Israel and the United States. From the previous solid-fuel missile development process, in the second phase of the development of the "Conqueror" missile, the "Persian Gulf", "Hormuz" anti-ship missiles and "Conqueror" 313 and other missile models with terminal guidance almost all used the precision guidance systems such as optoelectronics and satellite navigation developed by the "Chiam" liquid-fuel missile of the "Scud" series. By integrating liquid-fuel missile technology, the development of solid-fuel missile technology has been accelerated.

Main technical obstacles

Large engine design obstacles

Technology transfer from outside Iran has established a rocket industry system that can develop domestic solid propellants and engines. The complex is located in Sanan, 175 kilometers east of Tehran, based on the 140th Department of the Iranian Industrial Group and its predecessor organization. This is the main industrial group responsible for the solid fuel missile program. The Sanan Industrial Group has been expanding and has completed the development of more than 30 to 40 different solid fuel rocket engines. In addition to the solid engines required for the launch vehicle program and the ballistic missile program, it also designs and manufactures rocket artillery shells, anti-tank missiles, air defense missiles, air-to-air missiles, and anti-ship and cruise missiles. Due to less communication with the outside world, it can only design small rocket engines and lacks technology and experience for large engines. For this reason, Iran has tried to break the blockade and continue to improve its design and manufacturing level through introduction, but it has been suppressed by the West. For example, in the development of the 450mm diameter NP110 engine, the predecessor of the Conqueror series, Iran sought help from Russia in design and standard training. Although this is not restricted by the MTCR (Missile Technology Control Regime), the US government still imposed sanctions on the Baltic State Technical University, formerly the Russian Military Mechanical Academy, and its dean Yuri Savelyev. Although Iran has initially mastered the vector control technology of solid fuel engines through the "Thunder Missile Project", it is still unable to solve the vector control problem of large engines.

Lack of raw materials for large-scale production of solid fuels

Iran relies on its huge oil processing system to master the chemical technology of solid fuel production at a high level and has the production capacity of major raw materials, but the production capacity of raw materials such as aluminum powder to improve fuel performance is limited. In September 2010, Singapore intercepted a batch of 302 barrels of aluminum powder shipped to Iran. Missile experts believe that the high-purity aluminum content of this powder indicates that it may eventually be used in the production of solid propellants for missiles. In fact, there are rich bauxite deposits on the desert edge of the northern part of Khorasan Province in northeastern Iran. About 10 kilometers northeast of the city of Jajam, there are 302 barrels of aluminum powder. An aluminum production complex is built at 1,000 meters and is stationed with the elite Islamic Revolutionary Guard Corps. The complex mainly produces aluminum powder. Aluminum powder is widely used in products ranging from paints and electronics to solar panels and fireworks. Due to the explosive properties of aluminum powder, it is also a key component of solid fuel propellants used to launch rockets and missiles. When it is mixed with oxygen-containing substances, it releases a large amount of energy. Iranian officials said the facility played an important role in "increasing the country’s self-sufficiency in the production of solid fuel for missiles." However, due to the low level of production technology of the enterprise, it can only meet the general solid fuel production needs, and high-efficiency aluminum powder is still needed. Imported.

The manufacturing of new composite materials is difficult

At the beginning of this century, Russian companies provided Iran with high-quality steel, special alloys for missile shells, and metal sheets to protect navigation systems. However, in recent years, Iran’s new composite material design and manufacturing technology threshold is high, and the demand is also large. Iran can only introduce technology for independent production, which makes it more difficult to obtain new composite materials with carbon fiber as the core. The carbon fiber here refers to the carbon mass accounting for 90%. The above fibrous carbon materials. Carbon fiber is compounded with resin, metal, ceramic and other matrices to make carbon fiber composite materials (CFRP). As we all know, the important indicator of missile and aircraft design is weight. Reducing weight as much as possible without reducing strength is the goal pursued by every designer. Reducing the mass of the missile body by adopting new materials is almost the only way for the development of missile weapons in all countries in the world. Calculations show that the structural weight of the first, second and third stage engines of long-range missiles is reduced by 1 kg respectively, and the missile range is increased by about 0.6, 3 and 16 kilometers accordingly. Therefore, structural weight reduction of the shell, especially the shell of the last stage engine, has become one of the important technical ways to increase the range of missiles. Although carbon fiber is light and strong, it has the same problem of poor formability as various fiber products such as glass fiber, and it is difficult to shape it into various required shapes. Usually there are many composite material molding processes, such as layer stacking molding process, spray molding process, winding molding process, pultrusion molding process, etc. The key to the molding process is the molding equipment, especially the CNC fiber winding machine. The high-efficiency models of these raw materials and equipment are strictly controlled in the international market, and Iran has great difficulty in obtaining them. At present, Iran can only manufacture smaller carbon fiber parts through commercial equipment, and the Thunder missile parts are likely to be manufactured in this way. The larger carbon fiber parts required for Iran’s medium and long-range missile engines are still difficult to manufacture.