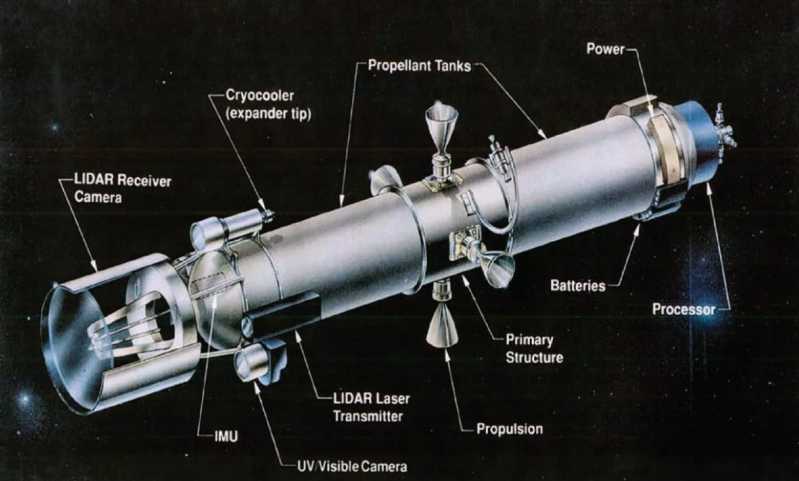

Transmitter

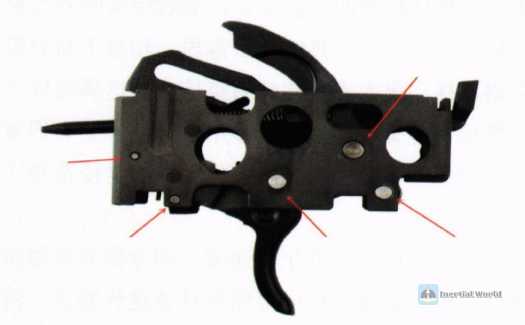

In the eyes of modern people, the modular transmitter used in the Type 63 rifle is a very trendy design. But unlike what everyone imagines, the modular transmitter was born very early. For example, the hammer assembly of the TT-33/54 pistol and the transmitter of the SKS/56 semi-automatic pistol are modular. The modularization of the past is different from today’s modularization. Today’s modularization is real modularization, and its design purpose is to facilitate the switching of different functions. The modularization of the past was actually just a packaging concept. Among the various components of the firearm, the transmitter is a typical "fragmented product". It has many parts and complex matching relationships, and it is also troublesome to produce and assemble. If the transmitter can be packaged in a "big box", some complex matching relationships, such as the matching, guidance, and limit locks between the trigger, sear, and hammer can be locked in the box, leaving only a few interface sizes and the matching of parts such as the receiver and automatic machine, it can greatly simplify the matching relationship of the firearm and reduce the design difficulty of the automatic machine and the receiver.

To give an example, the components in the transmitter are like primary school students. There are many of them and they are difficult to manage. Therefore, the teacher has to divide the primary school students into groups and appoint group leaders to be responsible for various tasks. The "big box" of the modular transmitter actually plays the role of the group leader.

But as a price, the modular transmitter will inevitably have an extra "big box", that is, the transmitter seat (also understood by some people as the second layer of the receiver) will occupy more structural space. If the transmitter design of the firearm is relatively simple and the coordination relationship is not so complicated, there is no need to design a "big box". For example, the AK and M16 rifles do not have a transmitter seat. And the MP5 The transmitter of a submachine gun is relatively complex and has many small parts. It is necessary to design a transmitter base to package the transmitter into a module.

But in my opinion, even if the transmitter of a gun is not complicated, it is meaningful to design a "big box". This is related to my personal preference. As a good socialist youth who loves hygiene, I have always been obsessed with cleanliness. I often wipe the guns I touch clean, even some corners, I will use a toothbrush to carefully wash. However, for the receiver of the AK/56, I can only sigh at the "box"-the space where the transmitter is installed in the receiver is extremely small and full of gullies. Even a toothbrush cannot reach in. If you want to wipe it clean, you can only remove the transmitter.

Disassembly 56 It is a hassle to flush the launcher. We need to use special tools (such as tying the hammer spring foot with a rubber band), and pay special attention to avoid losing small parts (such as the single-shot sear spring). The parts of the launcher are located inside the receiver, and the operating space is very limited, making installation very difficult. My junior once complained: "There is no place to hold the parts where you can put your fingers, and there is no place to put your fingers where you can hold the parts steady. "Even if the whole process goes smoothly: the disassembly and assembly process takes a long time, and the fingers are often "ravaged" and red.

Relatively speaking, the 56-stroke transmitter is easy to disassemble. To put it bluntly, there are only two types of transmitter disassembly and assembly: difficult and more difficult. If a modular design can be adopted, the entire transmitter can be easily disassembled and the inside of the receiver can be cleaned. As for the disassembled transmitter, it will be easier to clean itself without the obstruction of the receiver.

The 63-type rifle uses a modular transmitter, which is very rare, but the 63 The modular transmitter of the 63-type has a big disadvantage. It is easy to disassemble but difficult to install, especially the long safety that is out of place, which is like an antenna and is very troublesome. When the shooter assembles the transmitter, he needs to press the safety at a specific angle, and then let the safety drill into the receiver like drilling a tunnel, and then get stuck in the small clearance slot on the automatic machine track.

When I first came into contact with the 63-type, it took me half an hour to figure out how to install the transmitter. I was shocked and called a few junior brothers to try to install it. The junior brothers have come into contact with many firearms and can be regarded as experienced, but without exception, they all encountered difficulties when installing the transmitter, and they all felt that the installation logic of the 63-type transmitter was extremely strange. In addition, compared with the 56-type, the 63-type transmitter is obviously closer to the SKS/56 semi-automatic, which also makes me feel a little puzzled. Among the firearms of the 1960s, the transmitter of the AK rifle is certainly not perfect, but it has a very compact structure, is extremely strong, and has a trigger force of more than 100%. SKS, M16 and other peers and predecessors are better. But for some reason, the 63-type transmitter is still basically the same as the SKS/56 semi-transmitter.

Of course, I am not saying that the SKS/56 semi-transmitter is useless. The SKS/56 semi-transmitter adopts a modular design and is very compact. In addition, the hammer spring of the SKS/56 semi-transmitter uses an easy-to-process cylindrical spring instead of the special-shaped torsion spring used in AK. But even so, I still think that the 63-type is a wrong way to develop the SKS/56 semi-transmitter. Having said that, the overall layout of the 63-type is highly similar to the SKS/56 semi-transmitter. On this basis, the use and improvement of the SKS/56 semi-transmitter can be regarded as a mature and less risky technical route.

Fast and slow machine

For For semi-automatic rifles like SKS/M1 Garand, the rifle has only two states: firing and safety. It is a very natural and ideal design idea to design the safety mechanism around the trigger. When the shooter touches the trigger with his finger, he can naturally touch the safety, thereby judging the state of the gun, which is very convenient to operate.

The speed selector of the 63 type is located on the right side of the gun body and in front of the trigger, which is very similar to the American M1 carbine. If the 63 type is a semi-automatic rifle, then the safety located on the right side of the gun body and in front of the trigger would also be a very ideal design. But the 63 type is an automatic rifle, and the speed selector has three gears: safety, semi-automatic, and fully automatic. The logic is relatively complicated, and the situation is very different.

When I touched the Type 63, I found that my right index finger could indeed easily touch the selector, but due to the limited space in front of the trigger, the lever of the Type 63 launcher is too short, and the rotation angle between the gears is also large. I can’t use my right index finger to turn the selector at all. I can only move my entire palm and use multiple fingers to turn it. The overall operation is very awkward.

At the beginning of the Type 63, most relatively new automatic rifles had completely abandoned the idea of designing a selector around the trigger, and instead moved the selector to the receiver, whether it is FAL, G3, M16, Vz.58 or AK. I personally think that the designers knew clearly the shortcomings of the Type 63’s speed selector, but they felt helpless. Under the premise of using the SKS/56 semi-layout and the “wood-covered steel” handguard, the Type 63’s speed selector really “had no place to be” and was not suitable for any place. In short, the defects of the Type 63’s speed selector were completely caused by the overall layout.

Position of the magazine release button

The Type 63 also has a very shady design. We have previously mentioned that the direct-insert magazine has only one fixing point, and the fixing method is not stable enough. It often requires a relatively deep magazine well to ensure the stable positioning of the magazine. The front-clip rear-hung magazine has two fixing points in front and back, and the fixing method is much more stable. Therefore, the front-clip rear-hung magazine only needs a very shallow magazine well to complete the positioning.

The magazine is not inserted deep enough into the receiver, so a “well platform” is needed to make up for it. In terms of appearance, the direct-insert magazine is often equipped with an exaggerated "well platform" protruding from the outside of the receiver, while the front-clip rear-mounted magazine often does not need a "well platform" - the part where the magazine is inserted into the receiver is very shallow, but the guide length is sufficient. Because of this, it is difficult for us to observe the magazine well of the front-clip rear-mounted magazine. However, when we disassemble the Type 63, we can see the magazine well structure of the front-clip rear-mounted magazine.

The Type 63 uses a front-clip rear-mounted magazine, but it is designed with a magazine well, which is also a "genetic disease" from the SKS/56 semi-rifle. The SKS/56 semi-rifle uses a magazine feed, and the magazine is often "deeply buried" and it is best not to protrude from the surface of the receiver to avoid hooking. Especially in the early bolt-action rifles: the magazines are "buried" very well, and it is not visible from the outside at all, just like burying mines.

The SKS/56 semi-high adopts the design concept of bolt-action rifles, and the magazine is buried deeper. The 63 type also adopts the design of the SKS/56 semi-high, so the magazine is buried deeper. The SKS/56 semi-high adopts a fixed magazine and does not require a "magazine well" for guidance, but the magazine that needs to be frequently disassembled and assembled does have this requirement. Therefore, the 63 type adds a magazine well buried in the handguard and below the receiver based on the SKS receiver, which creates a rare front-clip and rear-hanging magazine + magazine well design.

What surprised me even more was that the 63 type actually designed the magazine release button on the transmitter, which confused me a lot. From a common sense point of view, it is best not to split the magazine well into two parts, but to adopt a packaged design concept to "lock" the relevant tolerances inside the magazine well. The magazine release button is one of the most important parts in the magazine well. The 63-type rifle has moved the magazine release button to the transmitter, so the transmitter and the magazine well must have a relatively close fit.

The 63-type uses a modular (encapsulated) transmitter, which greatly simplifies the fit relationship and helps reduce the difficulty of design and manufacturing. However, the magazine release button on the transmitter increases the difficulty of design and manufacturing. Just when I was puzzled, my junior brother reminded me: The magazine release button of the SKS/56 semi-automatic rifle is also located on the transmitter, and the 63-type rifle may just continue the design routine of the SKS/56 semi-automatic rifle.

The junior brother’s words briefly pulled me back from confusion. However, the more I thought about it, the more wrong it seemed: the Type 63 is indeed likely to have continued the magazine release button design of the SKS/56 semi-automatic rifle, but this approach is very inappropriate. After all, magazines and magazines are two completely different things!

First of all, the SKS/56 semi-automatic rifle uses a magazine. Although the magazine can be removed, there is no need to disassemble it during daily maintenance and use, and the magazines are not interchangeable at all (each gun has only one, so there is no need to replace it). Therefore, for the SKS/56 semi-automatic rifle, even if the tolerance between magazines is large and there is no interchangeability, it is not too outrageous.

Moreover, the SKS/56 semi-propelled magazine release button is similar to a sliding door, and its main movement is translation. The coordination relationship between it and the magazine is similar to the spring-type small bolt on the anti-theft door (I commonly call it a small lock, which is different from the large lock that needs to be turned several times with a key). This translation mechanism can inherently compensate for the gap in spring force, and the magazine is rarely removed and is not interchangeable. In this context, although the design of the magazine release button of the SKS/56 semi-propelled magazine on the launcher is unscientific, it is not too weird.

The 63 type uses a magazine feed, and the magazine needs to be frequently removed and installed, and the magazines need to be interchangeable. In addition, the magazine release button of the 63 type is a rotary type, not a translation type. The rotary release button is very convenient to operate, and the gap can also be compensated by angle, but the gap compensation effect is far inferior to the translation type. In short, the magazine + rotary magazine release button of the 63-type is completely different from the magazine + sliding magazine release button of the SKS/56 semi-automatic rifle. The 63-type rifle adopted the design of the SKS/56 semi-automatic rifle, which can be regarded as jumping into the river by feeling the stones.

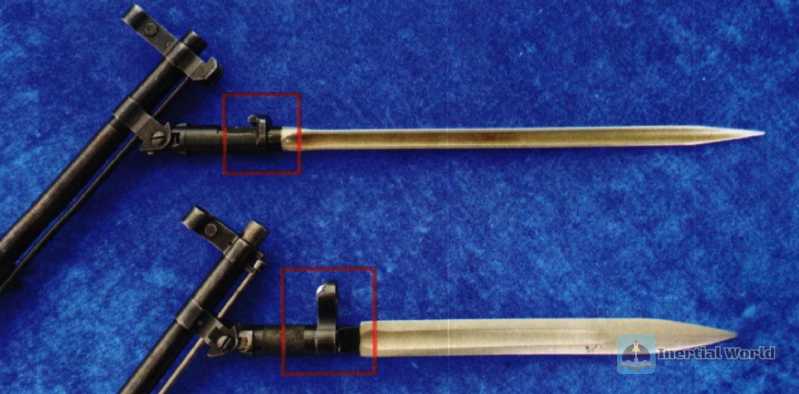

Bayonet

When explaining the SKS/56 semi-automatic, I have emphasized that the fixed folding bayonet is an extremely backward design, which will greatly deteriorate the center of gravity of the firearm. For the semi-automatic SKS, the bayonet is already very embarrassing-SKS is a semi-automatic weapon! The firepower was outstanding at the time, and they still wanted to fight with a bayonet?

Based on the same reason, the fixed folding bayonet of the 63 type is even more of a disaster. The 63 type is an automatic rifle! Unless the ammunition is exhausted, who would fight with a bayonet with an automatic rifle? Of course, some people will say that if there is no bayonet, what if the ammunition is exhausted? What’s more, our country must be prepared for a total war. In a total war, it is inevitable that there will be a shortage of guns and ammunition.

However, in modern warfare, what is the probability of running out of ammunition and food? If there is really a shortage of guns and ammunition, and you need to fight with bayonets to save ammunition, why do you want to develop automatic rifles? Automatic rifles are definitely big consumers of ammunition? What’s more, even if you really want to fight with bayonets, can’t you design a multifunctional bayonet that can be detached?

In short, I firmly believe that fixed bayonets and automatic rifles are two completely contradictory concepts. Equipping automatic rifles with fixed folding bayonets is completely absurd, just like Lin Daiyu pulling out weeping willows and Lu Zhishen weeping to bury fallen flowers. Although the fixed folding bayonet of the Type 63 is ridiculous, putting aside the background of the times, the Type 63 can be regarded as excellent in terms of the design of the fixed folding bayonet.

The triangular bayonet itself is a very excellent bayonet structure. Although it cannot cut or cut, the triangular bayonet has excellent rigidity. It can maintain high strength and low weight while ensuring the length. It is simple in shape and does not need to be sharpened. It is extremely easy to process. The requirements for tool materials are very low, and the requirements for heat treatment are even lower. It can be regarded as a fighter among cheap bayonets. The Type 63 bayonet is chrome-plated like the Type 56 and a half, and has excellent rust resistance. The essence of the bayonet lies in stabbing. The triangular bayonet is long and sharp, and is very competent in this regard.

From the perspective of the fixed interface, the ring buckle of the 56 semi-bayonet is not difficult to process and the cost is not high, while the Type 63 is changed to a cheaper "L"-shaped buckle, which can be regarded as one of the simplest bayonet fixing mechanisms, and the strength is still sufficient. Sometimes I feel that if the Type 63 fixed folding bayonet could be born during the First World War or even earlier, it would definitely become a generation of magic swords in the history of swords. It’s just that in the 1960s, such a design seemed out of tune with the trend of the times.

The so-called "rifle and submachine gun combined into one"

After we have finished talking about the structure of the Type 63, let’s look back at the concept of "rifle and submachine gun combined into one" of the Type 63. The so-called rifle and submachine gun combined into one refers to the submachine gun (Type 56 submachine gun/AK47) and rifle (Type 56 semi-automatic rifle/SKS) combined into one. As a general-purpose gun that combines two into one, the Type 63 should be as easy to use as the Type 56 semi-automatic rifle, and have fierce firepower like the Type 56 submachine gun.

However, in my opinion, the combination of rifle and submachine gun is a false proposition - the Type 56 submachine gun is originally a rifle! It is not a submachine gun at all, but a qualified, epoch-making rifle that will remain advanced for decades to come. The so-called rifle and submachine gun combined into one is essentially "a semi-automatic rifle and an assault rifle combined into one", which is completely unnecessary. The assault rifle itself is the product of "integration of rifle and submachine gun", a fusion product of rifle (bolt-action, semi-automatic) and (real) submachine gun. It is really unnecessary to combine the Type 56 and Type 56 semi-automatic again.

Moreover, combining two into one will always have a bias, and it is impossible to treat them equally. For example, the MG34 and MG42, which are known as general-purpose machine guns, are huge in size and length, and are more inclined to heavy machine guns rather than light machine guns. As a product of combining two into one, the Type 63 is also biased. It is a pity that the Type 63 is biased in the wrong direction. It is not biased towards the revolutionary Type 56 but towards the extremely backward Type 56 semi-automatic. To put it bluntly, the Type 63 is just a continuous-fire Type 56 semi-automatic.

After World War II, it was the era of automatic rifles. Although some countries took a detour, the new generation of firearms, such as Vz.58, FAL, G3, etc., have all walked out of the shackles of bolt-action and semi-automatic rifles like AK47. When developing the Type 63, China had already equipped a certain number of Type 56 assault rifles, and we had already stepped half a foot on the road to advanced assault rifles. However, the Type 63 went the other way. In the name of a universal rifle that combines rifles and assault rifles, it took a step back in actual behavior and pulled domestic rifles back to the design framework of semi-automatic rifles. In short, whether it is the concept or the result, the combination of rifles and assault rifles is not a success.

Is the traditional layout of the Type 63 for bayonet fighting?

Some people also believe that the Type 63 uses a layout framework similar to the Type 56 semi-automatic rifle for bayonet fighting. I do not agree with this statement.

Everyone must understand that bayonet fighting is a very small link and has little to do with the overall layout of the gun. The Type 63 uses an old layout similar to bolt-action and semi-automatic rifles, rather than the "new" layout of the Type 56 rifle. From the perspective of bayonet fighting, the old layout is indeed better than the new layout, but how much better can it be? Does the Type 56 rifle suffer a lot when bayoneting? Compared with the tiny advantage of bayonet fighting, the overall layout of the gun has a huge impact on the performance of the gun. I would rather believe that people at that time had a poor understanding of the development of firearms than that the designers ignored the advanced layout of the 56-type rifle and adopted the extremely backward SKS/56 semi-type layout for the sake of a tiny bayonet advantage.

Why can’t we make a good rifle?

About a dozen years ago, my family bought a women’s motorcycle for my mother to use for commuting to work. However, this domestic motorcycle was very disappointing. Every winter, this motorcycle was broken and repaired repeatedly.

Now it seems that this motorcycle brings almost as much convenience and trouble. Dad often complained when he was repairing the motorcycle. He couldn’t understand why the quality of domestic motorcycles was so poor when we could make satellites, atomic bombs, and missiles. I didn’t quite understand this question back then, but now I have gradually come to my own understanding.

To put it bluntly, although atomic bombs and missiles are high-end, they are just high-tech disposable products. Cars and firearms are unlikely to do this - it is difficult for a family to have the financial resources to buy two motorcycles for commuting at the same time. To put it bluntly, there is a huge difference between high-tech disposable products and seemingly low-tech, mass-produced durable goods.

In the early stage of the development of the Type 63, there was a similar slogan in China: We have already developed the atomic bomb, so why can’t we develop our own rifle? Although the rifle does not seem to have any technological level, it is also a product of hundreds of years. It is a typical durable product produced in large quantities and a typical firearms powerhouse of "long-term investment". For example, Germany, Switzerland, Belgium, and Austria are almost all old industrial countries with more than 100 years of firearms design and manufacturing foundation. In contrast, my country was in the technical stage of imitating foreign firearms at that time, which was barely considered a start. Once it started independent research and development, it would definitely face many problems.

It was in this context that the design and processing of the Type 63 became a tragedy. From the perspective of guiding ideology, the concept of combining rifles and assault rifles is essentially out of date, and its starting point of cognition is even completely wrong. From the design perspective, the Type 63 uses the layout framework of the 56 semi-/SKS, which has buried huge hidden dangers. From the production perspective, the production of the Type 63 is a greater disaster.

Sometimes I think that when developing the Type 63 rifle, my country did not intend to overturn the Type 56 rifle bullet that was copied from the Soviet 7.62x39 mm M43 bullet. If my country had also developed new bullets and distributed them to the Type 63, there would definitely be more problems. The gun and bullet are small, but not small; the gun and bullet are light, but not light. The success of any industry must be the result of countless lessons learned, and it will never be "He can do it, why can’t I?

From another perspective, the failure of the Type 63 is also the "tuition fee" we must pay, just like the bumps and bumps when learning to ride a bicycle. Everyone is on the road to success through countless failures. Too smooth success is a kind of luck, and countless setbacks are the norm. The Type 63 uses its own painful experience to tell us that firearms should not be designed in this way.

From imitation to self-research, this road is not easy to walk. We will definitely have bumps and even bloody heads. Let me end with a more popular Internet term: The Type 63 is the tears of the times. You can cry, but please don’t give up, let alone give up on yourself.