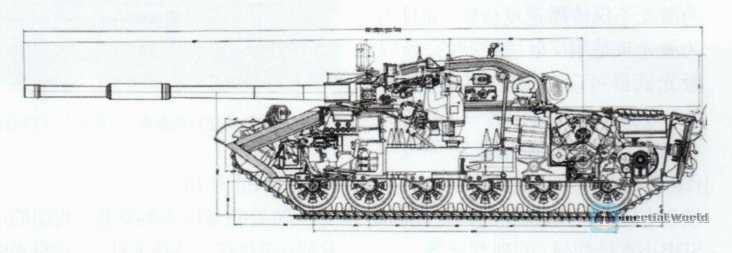

In 1974, the first T-72 main battle tank entered service in the Soviet Army. 50 years later, in 2023, its latest improved version, the T-72B3, is still the main tank of the Russian armored forces. Although the T-72 main battle tank is well-known worldwide, due to the Soviet armored vehicle’s habit of launching an improved model every few years but the naming method remains unchanged, it is often necessary to accurately understand the performance of the T-72 at each stage. Therefore, it is necessary to sort out the development context of this classic main battle tank.

Born from the shadow of T-64

Before developing the T-72 main battle tank, the Nizhny Tagil-Ural Design Bureau was lagging behind its competitor, the Kharkov Design Bureau. The only T-62 purchased in large quantities by the Soviet Army was regarded as an emergency plan to deal with the threat of Western L7 rifled guns at the time. Its next-generation main battle tank project, Project 167, was essentially a "T-62 modification" that improved the power system and adjusted the armor protection. Compared with the Kharkov Design Bureau’s Project 430, it had no technical advantages. The only advantage was that the technology was mature and could be put into production quickly. However, the Soviet military was obviously more interested in the more advanced Project 430, and Project 167 was eliminated as expected. In 1961, Project 430 was terminated, and its development model Project 432 received all the resources of Project 430. After failing to win the bid for Project 167, the Nizhny Tagil-Ural Design Bureau developed Project 167M with reference to Project 430/432. Compared with Project 167, it was completely improved. It was equipped with a horizontal loader, the upper front angle was increased to 68", the same as Project 432, and composite armor. Overall, Project 167M was not much worse than Project 432, but the prestige and status of Morozov, the chief designer of the Kharkov Design Bureau, was much higher than that of Kartsev, the chief designer of the Nizhny Tagil-Ural Design Bureau, and Project 167M was more or less suspected of "plagiarizing" Project 432, so the Soviet military was more concerned. The Soviet Union favored Project 432 of the Kharkov Design Bureau. In 1964, the Soviet Defense Technical Committee terminated the development of Project 167M on the grounds that it "did not meet the development prospects of Soviet tanks", and Project 432

Finally entered the Soviet Army with the number T-64. As the pioneering work of the Soviet Union’s third-generation main battle tank, the T-64 is undoubtedly an epoch-making product. It has laid a series of classic layouts such as a three-person crew plus an automatic loader and a 68" high-angle front. In contrast, West Germany had just equipped the Leopard 1 at the same time, and the US M60 had only been equipped for two years. The T-64 had an absolute advantage in quality over Western main battle tanks. However, the use of a large number of advanced technologies also led to the extremely poor reliability of the T-64. Even when the improved model T-64A was designed and finalized in 1968, the reliability problem could not be solved, which was difficult for the Soviet military to accept. In order to solve the reliability problem of T-64A, new design indicators were delegated to various design bureaus. It was with this opportunity that Nizhny Tagil-Ural Design Bureau was able to make a comeback in Project 167M, which it failed in the bidding.

After receiving the task of improving the reliability problem of T-64A, Nizhny Tagil-Ural Design Bureau first carried out Project 172, which was essentially a T-64A with a V-45K diesel engine and a loader and slight optimization. However, after many tests on T-64A, Kartsev believed that the design of T-64A was too compact, and it was far from being solved by replacing the engine to solve its reliability problem. Therefore, Kartsev finally decided to "steal the beams and replace the pillars" and launch Project 172M. On the basis of Project 172, the engine was changed to a V-46 engine with a maximum output power of 780 horsepower, the running mechanism was replaced with a large-diameter road wheel similar to Project 167M, and the turret was changed from composite armor back to cheaper cast steel. In essence, Project 172M is a Project 167M that borrows the configuration of T-64A. Compared with T-64A, its weight has increased to 41 tons, but the increased weight has achieved almost equal protection with cheaper armor materials, and the engine horsepower has also increased. Therefore, overall, Project 172M is only slightly behind T-64A in fire control equipment, and its protection and mobility indicators are basically at the same level. The Soviet military did not pursue this "heretical" behavior in the end, because although Kartsev did not improve T-64A as required, the Project 172M delivered by Nizhny Tagil-Ural Design Bureau fully met the requirements of the Soviet military. So in 1974, Project 172M was able to enter the Soviet Army under the code name of T-72, and the T-72’s 50-year service career began.

The first generation: the T-72 that laid the foundation

The T-72, which entered service in the Soviet Army in 1974, is the basic model of the T-72 series and has a "founding" status in the family. Many people also call the T-72 T-72Ural/T-72Ura1-1, but this is actually inaccurate. The Soviet/Russian official did not name the model T-72Ural/T-72Ural-1. In fact, from 1974 to 1978, in just five years, the T-72 had four sub-models: T-72 1974, T-72 1975, T-72 1977, and T-72 1978. Each sub-model has improvements of varying degrees. Obviously, the two models T-72Ural/T-72Ura1-1 cannot be used to distinguish them.

The official production model of the 172M project, the T-72 1974 model, is equipped with a 2A26 125mm smoothbore gun. The main armor-piercing projectile is the 3BM15 tail-stabilized armor-piercing discarding sabot (APFSDS) that entered service in 1972, with a penetration depth of 310mm/0° at 2000 meters. The fire control system is mainly the PD-2-49 daytime gunner’s sight with a combined image rangefinder. From the appearance, you can clearly see the square protrusion of its installation location: In terms of protection, the T-72 1974 model has the same formula as the T-64A, both of which are 8 The "sandwich" structure of 0mm homogeneous steel + 105mm fiberglass + 20mm steel, the turret is made of cast steel, and the heading angle penetration resistance reaches 310mm, but the damage resistance is poor, only about 410mm. This level of protection is more than enough to face armor-piercing shells such as the M728 armor-piercing discarding sabot (APDS), and can also reduce the effective penetration distance to within 1000 meters when facing the M735 tail-stabilized armor-piercing discarding sabot, but the turret protection is slightly insufficient when facing the shaped charge warhead. The T-72 1975 model has some improvements on the details of the T-72 1974 model. It moves the infrared headlight to the right side of the turret to facilitate the driver’s entry and exit; installs a heat shield for the gun; changes the antenna position and changes the default direction of the installed NSVT anti-aircraft machine gun to face the rear of the turret.

The most important improvement of T-72 1977 is the replacement of the composite armored turret with quartz sand interlayer, which improves the previous T-72 turret’s poor anti-breakage ability. In addition, the main gun is also replaced with the 2A46 125mm smoothbore gun with higher shooting accuracy. T-72 1978 replaced the brake device on the basis of 1977, improved the track and added a skirt, but since T-72 1977 also added a skirt later, and other improvements are not obvious in appearance, T-72 1977 and T-72 1978 are difficult to distinguish in appearance.

The second generation: the famous T-72A

Due to the low technical level of the T-72, especially the shortcomings of the observation and aiming equipment being too simple, its production lasted only five years before it was hastily ended. The T-72A, which was put into service in 1979, is considered by many to be the true basic model of the T-72 series. The T-72A1980 model with a new turret that appeared at the Red Square parade in 1983 gave a great shock to Western countries. At the same time, the T-72M/M1 developed based on the T-72A was also used as an export model in large quantities in Yugoslavia/Serbia, Syria, the Czech Republic, Slovakia, Poland and other Warsaw Pact or third world countries. It can be said that it was the T-72A that made the T-72 series the third representative tank of the Soviet Union after the T-34 and T-54.

172M-1 project is the experimental model of the T-72A, which still uses the V-46-6 engine; the main gun is replaced with the 2A46-1 125 mm smoothbore gun, which has improved shooting accuracy and barrel life compared to the 2A26/2A46, and the main armor-piercing projectile is also replaced with the 3BM22 fin-stabilized discarding sabot armor-piercing projectile that entered service in 1976. This armor-piercing projectile is used as a benchmark against the DM13/M735 The product became the strongest armor-piercing projectile in the Soviet Union in the 1970s. Its penetration at 2000 meters reached 390 mm/0” or 160-170 mm/60°, which was a significant improvement over the 3BM15. In addition to replacing the main gun, improving the T-72’s overly simple fire control system was also an important direction of the 172M-1 project. Its gunner’s scope was a TPD-K1 daytime gunner’s scope with a laser ranging function. However, it should be noted that some of the research and development results of the 172M-1 project were used in later batches of T-72. On the 1978 model, the TPD-K1 daytime gunner’s sight is one of them. Therefore, some T-72s sealed the original TPD-2-49 optical channel after replacing the TPD-K1 but retained the square protrusion. In terms of protection, the 172M-1 project adjusted the formula of the upper front composite armor to 60 mm steel + 105 mm fiberglass + 50 mm steel. Although the total thickness increased by only 10 mm, the increase in the thickness of the back plate weakened the cold shock effect to a certain extent, and increased the equivalent thickness of the long-rod armor-piercing projectile.

T-72A The 1979 model only made minor improvements to the 172M-1 project, adding an R-123M radio to improve the tank’s protection against napalm bomb attacks. Its command vehicle model is the T-72AK, with an R-130M radio and a retractable antenna.

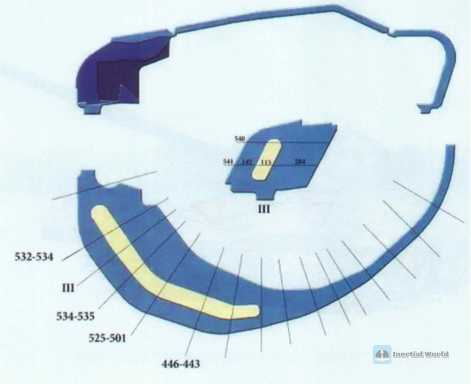

T-72A The 1980 model replaced a new turret with a thicker horizontal equivalent thickness (LOS). The turret was called the "Dolly Parton" turret by the US military. It has a clear curved edge on the lower front, with an equivalent penetration resistance of 410 mm and a burst resistance of about 500 mm. The penetration resistance is excellent, but the burst resistance is still slightly insufficient. The next few batches of the T-72A 1980 model installed smoke grenade launchers on both sides of the turret.

T-72 evolved into T-72A When it was 1980, it had a quality advantage over a series of second-generation and a half main battle tanks such as the Leopard 1 Improved Model and the M60 Improved Model that were in large quantities in the West at that time. The Fifth Middle East War in 1982 gave the T-72 an opportunity to test itself in actual combat. The T-72M put into combat in Syria belonged to the T-72M-E4 exported by the Soviet Union to third world countries. Its technical level was equivalent to the T-72A 1979 model body grafted with the T-721975 model turret and simplified three-defense capabilities. Actual combat has proved that the T-72M fire control system is weaker than Israel’s M60 upgraded Magach 3/4. It is difficult to hit enemy tanks at a distance of 2000 meters, but the main gun can penetrate Magach 3/4 without any pressure. However, what shocked the Soviet army the most was that Israel’s M111 armor-piercing projectile could effectively penetrate the upper armor of the T-72A and T-64B at a distance of 2000 meters, and at this time Germany also introduced and produced this armor-piercing projectile. Therefore, in order to deal with this threat, the Soviet army immediately launched the "Reflect" project, including the long-term "Reflect"-1 and the short-term "Reflect"-2. The former eventually gave rise to new main battle tanks such as T-72B and T-80U, while the latter directly welded high-hardness steel on the front of existing main battle tanks. Among them, the T-72A 1982 type (that is, the "Reflect"-2 enhanced type) has an additional armor thickness of 16 mm on the front, which makes its front penetration resistance reach 400 mm, and its protection capability has been improved to a certain extent.

The T-72A 1983 model is actually a continuation of the "Reflex"-2 project. In order to further enhance its protection capabilities, the T-72A 1983 model replaced the upper glacis armor formula, changing the original "sandwich" structure to a multi-layer spaced armor structure of 60mm steel + (15mm air + 15mm steel) x3 + 15mm air + 50mm steel. This structure is close to the upper glacis armor configuration of the later T-72B 1985 model. Although this type of multi-layer spaced armor may produce negative effects due to the ramming effect when facing rod-type armor-piercing projectiles, it may also produce positive effects by forcing the armor-piercing projectiles to enter the pitting stage multiple times. However, judging from the final performance, although this formula showed a good positive effect, it still failed to meet the Soviet army’s expectations. Therefore, the upper glacis formula was replaced again on the T-72B. In the same year, the 3BM26 fin-stabilized discarding sabot armor-piercing projectile entered service with the Soviet Army. The biggest improvement compared to the 3BM22 was that the armor-piercing body was moved to the tail to improve the center of gravity. At the same time, the front of the projectile played a cap-like role to protect the armor-piercing body. This improvement finally improved the dilemma of the Soviet armor-piercing projectiles with poor oblique penetration.

T-72A 1984 model, as the last T-72A, looks very similar to the pre-production T-72B that appeared in late 1984. It replaced the larger 172.10.077SB turret. The US military called it the super "Dolly Parton" turret. The curved edge of the lower front of the turret is so curved that it forms two small nests. It was changed from quartz sand sandwich armor to "reflector" multi-layer spaced armor and equipped with radiation lining. The 172.10.077SB turret had excellent protection in the early 1980s, with an angular penetration resistance of 540 mm, which could withstand frontal fire from most armor-piercing shells at the time. In addition to the updated turret, the T-72A 1984 model was also equipped with the 1A40 fire control system and the 840-horsepower V-84-1 engine for the first time, which improved its protection, firepower and mobility.

Third generation: Witness the glory of T-72B

Third generation: Witness the glorious T-72B

As the last T-72 improved model in the Soviet era, T-72B witnessed the last glory of the Soviet Army. With the support of 3B M32, 3B M42, 9M119 and improved armor formula, T-72B has achieved the design requirements of fighting against Leopard 2A4, MIA1 and other Western main battle tanks of the same period at a relatively low cost. Even after the disintegration of the Soviet Union, a large number of T-72Bs have become a valuable asset left to Russia, Belarus, Kazakhstan and other CIS countries.

The experimental model of T-72B is Project 184. The project started in 1981 with the aim of improving the fire control performance and mobility based on the T-72A. However, with the launch of the "Reflection" 1 project in 1982, improving protection became its focus. Finally, after absorbing some of the research results of Project 177 and Project 179, Project 184 and its parallel project Project 184-1 were finalized and produced in 1984 with the numbers of T-72B and T-72B1. There is no other difference between the two except that T-72B1 canceled the 9K120 "Svir River" gun-launched missile launch system and simplified the fire control. The difference between the T-72B 1984 and the T-72A 1984 is that the upper front armor formula was changed again, changing the 3 layers of 15mm air + 15mm steel to 2 layers of 10mm air + 10mm steel + 2 layers of 10mm air + 20mm steel, so that the upper front armor can withstand the short-rod tail-stabilized armor-piercing projectiles up to 485mm.

The T-72B 1985 is actually the first real T-72B, because the T-72B at the end of 1984 was not equipped with the "Contact"-1 explosive reactive armor when it was shipped from the factory. It was not until the T-72B 1985 that the factory standard explosive reactive armor kit was realized. For this reason, the Soviet/Russian main battle tanks after the T-72B 1985 no longer have a V in the name to indicate the installation of the explosive reactive armor kit. Although the "Contact"-1 only weakens the ability of shaped-charge warhead ammunition such as armor-piercing shells, this ability is extremely important for the T-72B, because the proportion of high-hardness steel in the composite armor of the T-72B is very high, which leads to its strong penetration resistance but relatively weak penetration resistance. This defect was also reflected in the previous five Middle East wars: most T-72Ms were destroyed by "TOW" anti-tank missiles rather than main battle tanks. After being equipped with "Contact"-1, the T-72B1985 model’s upper front and turret have a penetration resistance of about 900 mm, which can effectively defend against the "TOW" 2 anti-tank missile without a tandem warhead. In terms of firepower, the T-72B 1985 model is the first T-72 improved model with the ability to launch gun-launched missiles. The missile launched by its 9K120 system is the 9M119 "Reflection", with an armor-piercing thickness of 700-800 mm, a maximum flight speed of 445 meters per second, an effective range of 400-5000 meters, and beam-riding guidance. Gun-launched missiles are another important combat capability supplement for the T-72B: Even with the 1A40 fire control system, the shooting accuracy of the T-72B is still behind that of Western main battle tanks. However, after being equipped with gun-launched missiles, the T-72B has a precision strike capability of more than 2,000 meters, while the shooting accuracy of Western main battle tanks begins to drop sharply above 2,000 meters, which gives the T-72B an asymmetric strike capability, offsetting its disadvantages caused by insufficient fire control to a certain extent.

The T-72B 1989 model once again replaced the upper front armor structure based on the T-72B 1985 model, but this T-72 is still classified as a sub-model of the T-72B rather than the new T-72C. The formula of the upper front armor is: 60mm steel + 5mm rubber + 3mm steel + 19mm gap + 3mm steel + 5mm rubber + 60mm steel + 10mm radiation lining + 50mm steel. In addition, the explosive reactive force of the equipment has been changed from "Contact"-1 to "Contact"-5 explosive reactive force, which is both resistant to damage and penetration. The installation method of the explosive reactive force has also changed. The explosive reactive force on the upper front is integrated into the "Contact"-5 embedded protection component. The explosive reactive force on the turret is no longer installed close to the base armor, but is arranged in a V shape through a bracket similar to the T-72AV. The tilt angle is larger, the protection capability is better, and the appearance is simpler and more beautiful. This improved model has a very obvious improvement in protection. With the support of "Contact"-5, the penetration resistance of its upper front armor has reached 600mm except for the triangle area, which can withstand the shooting of DM33 armor-piercing projectiles that entered service in the same year. Therefore, the T-72B 1990 model only made minor improvements on the basis of the T-72B 1989 model, replacing the fire control system with 1A40-1 and equipped with a DVE-BS crosswind sensor.

The fourth generation: the T-72B improved model with heavy responsibilities

After the disintegration of the Soviet Union in 1991, the newly born Russia was unable to maintain many advanced tank research and development projects during the Soviet era. The famous Project 640 and Project 195 were successively discontinued due to funding issues during this period. However, with the service of new Western main battle tanks such as the Leopard 2A6 and M1A2 in the mid-to-late 1990s, improving existing models to improve the combat capability of armored forces became one of the important tasks of the Russian army in the early 21st century. The three improved T-72B models, T-72BA, T-72B2 and T-72B3, as the fourth generation T-72, have taken on the main responsibility of the Russian armored forces.

The earliest T-72BA was actually a project proposed by the Ural Factory in 1993 to overhaul and modernize the T-72B 1985 model. The focus of the project was to improve the fire control and electronic equipment and raise the protection level to the level of the T-72B 1989/1990 model. In terms of firepower, the fire control system was replaced with 1A40-1M, the TKN-3 night commander’s observation mirror was replaced with TKN-3MK, and the L-4 infrared headlight was replaced with the PL-1 infrared laser emitter. These modifications have enhanced its night combat capability, but there is still a clear gap with the new Western main battle tanks. In terms of artillery, although the old 2A46M is still used due to cost reasons, the loading machine has been improved to make it compatible with armor-piercing shells with a total length of 3BM59/60 to improve the ability to resist armor-piercing shells. In terms of power, the early T-72BA still uses the 840 horsepower V-84M engine. After 2003, the 1000 horsepower V-92S2 engine can be optionally installed, but the gearbox has not been changed, so the disadvantage of only -4 kilometers per hour reversing speed has not been eliminated. However, after the T-72BA passed the national test in 2000, not all T-72BAs received the above modifications. The protection of some T-72B 1985 models has not been improved, but only the firepower and mobility have been improved. This situation can also be explained by reducing costs. After all, some troops in the Central Military District of Russia were still using T-72A until the outbreak of the Russian-Ukrainian conflict. But obviously, no matter which T-72BA model, its performance still cannot meet the needs of the new era, so in 2005, the 184M project, a deeply improved model of the T-72B, began to be developed.

184M project is the development stage code of T-72B2 "Jiuma"-1. Its improvement compared with T-72B is comprehensive. In terms of firepower, the most important improvement is the "Pine"-U day and night integrated thermal imaging gun telescope, which makes the T-72 series have a thermal imaging system for the first time, and its all-weather combat capability is greatly improved. In order to cooperate with the major upgrade of fire control, its main gun is replaced with a 2A46M-5 smoothbore gun with better shooting accuracy. When firing the 3BM59 "Lead-1" tail-stabilized armor-piercing projectile, the penetration depth is 340 mm/60° at a distance of 2000 meters, which is roughly the same level as the M829A2. In terms of protection, the 184M project replaced the "Contact"-5 with a more advanced "Fossil" explosive reactive kit, which made the 184M project look very similar to the T-80BVM after removing the anti-break rubber curtain of the turret. With the support of the "Fossil" explosive reactive kit, the 184M project’s upper frontal penetration resistance reached 700 mm when facing armor-piercing shells such as the M829A2 that are not specially designed for heavy explosive reactive weapons, and the frontal penetration resistance of the turret is close to 800 mm. In addition to hard protection, the 184M project also has a laser warning device for the "curtain" infrared jamming system and a "cloak" camouflage cloth that is said to reduce infrared signals by 30%. In 2005-2006, when active protection systems were not yet equipped in large quantities, such soft protection capabilities were already at the world’s advanced level. In 2007, the 184M project passed the national test and subsequently obtained the production model of the T-72B2, but unfortunately, the T-72B2 was ultimately not mass-produced because Russia was short of money and could not purchase the more expensive T-72B2. However, the T-72B2 is considered to be a pioneer in the deep modernization of Soviet tanks, and its improvement experience has laid a solid foundation for the later T-72B3, T-80BVM and T-90M.

After the T-72B2, Russia finally achieved a balance between performance and cost on the T-72B3 instead of pursuing all-round improvement. And because this model was successfully mass-produced, it continued the characteristics of the Soviet/Russian tanks with many sub-models, including the 2011, 2013, 2014, 2016 and 2022 models. The T-72B3 2011 and 2013 models only improved the gun and fire control on the basis of the T-72BA; although the T-72B3 2014 model has advanced subsystems such as the commander’s periscope and the V-92S2F engine, its production is extremely low and it is almost only used as a vehicle for the "Tank Biathlon" competition. The T-72B3 2016 model, namely the T-72B3 UBH, as a mature model, represents the improvement standard of the T-72B3: in terms of firepower, it continues the configuration of 2A46M-5+"Pine"-U of the T-72B2; in terms of protection, the 4S22 explosive block in the "Contact"-5 ERA is replaced with the 4S23 in the "Fossil" ERA, and the "three-plate" kit on the side of the vehicle body inherited from the Soviet era is replaced with a rubber skirt to facilitate the installation of a soft 4S24 ERA with enhanced anti-break capability, and a boxed 4S24 ERA is also installed on the side and rear of the turret. In terms of mobility, in addition to the V-92S2F engine used on the T-72B3 2014 model, a new gearbox with an automatic shifting system has been installed, which improves the flexibility of the vehicle and reduces the operating pressure of the driver, but the "hard-to-solve" problem of the reverse speed of -4 kilometers per hour has not been solved. As an improved model with wartime colors, the T-72B3 2022 model has further strengthened its protection. At the same time, a considerable number of T-72B3 2022 models do not have "Pine"-U when they leave the factory, but use the poor-performing 1PN96MT-02 thermal imaging gunner’s telescope. The reason is probably that after Russia’s partial mobilization, the "Pine"-U production was insufficient and was installed on tanks with higher priority, such as T-90M and T-80BVM. In general, the T-72B3 has basically reached the technical level of the T-72B2 at a relatively low price, and its production can also meet the requirements of the Russian army at this stage. There is no doubt that the T-72B3 is still difficult to compete with the world’s top main battle tanks, but for the Russian army with a large armored force, the T-72B3 is an excellent product with high cost performance.

Conclusion

From the above development context, it can be seen that the improvement of T-72 in the Soviet period was centered on enhancing protection capabilities, while in the Russian Federation period, it was centered on improving the fire control system. This reflects the development of the world’s mainstream tanks in the two periods of the Cold War and the post-Cold War: during the Cold War, the competition for armored shells was fierce, and the fire control system as an auxiliary equipment was still in a secondary position. In the 21st century, with the rapid development of electronic technology, the fire control system has become more and more advanced and more and more important. Therefore, even though the price of "Pine"-U is high, Russia has not canceled this upgrade project on the T-72B3. As a main battle tank that has been in service for 50 years, the T-72 has always been considered the "goalkeeper of the third-generation main battle tanks". In the foreseeable future, the T-72 will continue to be in battle and continue the glorious journey of a veteran of the Cold War.