Follow the American path

Among the new conventional weapons platforms spawned by local wars after the war, armed helicopters are a relatively special type. Almost all countries have chosen to start with the existing models and make major changes. Of course, the reasons are quite different. Some are due to the urgent need of the front line, some are due to the relatively limited technical foundation, and of course more often it is the result of the combined effect of various factors. But in any case, the preliminary theoretical preparations are a hurdle that cannot be avoided. Why is it necessary to develop armed helicopters? What can armed helicopters be used for?

These two questions require military departments and technical research units to reach a consensus first. The Mil Design Bureau, which led the design of helicopters in the Soviet Union, had long foreseen that helicopters would play a big role on the battlefield in the future, and it was not just as simple as taking on the evacuation of the wounded and front-line liaison. However, in order to prove its huge potential, it is necessary to convince key figures in the military first. In the context of the theory of victory in nuclear war that permeated the decision-making bodies, there was no future in expanding the flight performance and military functions of helicopters. Khrushchev disdained helicopters, and Defense Minister Malinovsky was even more opposed to armed helicopters.

Fortunately, there were still some people who understood - Deputy Defense Minister Grechko was more open-minded. He believed that Mikhail Miri’s plan was completely feasible and of immeasurable value. But the General Secretary intervened immediately and asked senior military officers to "stop such boring discussions" because armed helicopters, heavy tanks, and aircraft carriers were all big and useless "waste". It seems that the only obstacle to the development of helicopters in the Soviet Union was Khrushchev, and the only way out was to wait for him to step down, or to... shh, keep your voice down.

At that time, the military exchanges between the Soviet Union and the West were not completely cut off. Miri was invited to visit the Paris Air Show in 1965. He had a general understanding of the development level of the aviation industry in European countries and believed that at least in the field of military helicopters, the Soviet Union’s backwardness was beyond doubt. French helicopters have been generally armored and can carry anti-tank missiles for combat, while the Soviet Union has almost no similar models related to weapons. Of course, these are only development trends under peaceful conditions. The truly valuable information still needs to be obtained from the battlefield in a timely manner.

The Soviet Union is very concerned about the trend of the US Army to establish an air mobile infantry unit. It seems necessary to take reciprocal measures, but directly copying it will definitely not work. Apart from anything else, where will the helicopters come from? At that time, the Soviet Union could not find a model of the same level as the UH-1 Huey. The Soviet Union had small helicopters like the Mi-2, but their performance was far inferior, and the troop compartment could not hold many people. The Mi-8 was large enough to hold a platoon, but its mobility could not keep up, not to mention other heavy aircraft. The Mi-2 and UH-1 were considered to be a mix, the so-called B-22 plan - although Mikhail himself was not optimistic about the design. Unless the enemy could not organize a decent air defense layout, a light helicopter with weak protection like the UH-1 would be a target on the front line, and even infantry weapons like the AK-47 could cause serious damage to it.

Soon Mikhail decided to enhance the armor of the B-22 and proposed the B-24 concept platform - 0.3-inch protective armor and short wings with pylons (with anti-tank missiles below), 23mm twin-barreled aircraft guns (on the right side of the fuselage). Mikhail called this new design the Infantry Flying Fighting Vehicle (ЛБMI) or Infantry Combat Helicopter (БMI). From the full-size model, this concept aircraft is highly similar to the UH-1. The fuselage cross-section is roughly a square box, and the power unit located at the upper rear position is larger. Behind the parallel double cockpit is a troop transport cabin carrying 8 armed personnel, and above the end is a large long and short wing, with two anti-tank missiles on each side. Like the Huey, this aircraft uses a sliding landing gear, but the rotor system seems to have directly adopted the three-blade design of the Mi-2. Except for a few conservatives such as Defense Minister Marshal Malinovsky who are skeptical about the B-24 and believe that it is difficult to leave a suitable position for it in the future Army Aviation, open-minded military personnel are quite surprised by this plan. After all, the protection level of the Il-2 attack aircraft at that time was just like this.

The Ministry of National Defense recognized the design concept of the Mil Design Bureau in principle, but it did not mean that it would definitely accept the B-24 plan. First of all, a design tender must be held, and Mil must first compete with the Kamov Design Bureau. Fortunately, Kamov was not mentally prepared in advance. They could only slightly modify the nose of the Ka-25 carrier-based aircraft, add a skid, and symbolically insert a machine gun in the lower jaw. Such a makeshift work certainly could not be recognized by the military, but Mil was fully committed. The technicians simultaneously launched multiple modification plans with different sizes and power. On one hand, it was a single-engine modified on the basis of the B-22 (total weight of about 7.7 tons), and on the other hand, it was an 11-ton twin-engine heavy armed helicopter, which was the turbine-powered concept aircraft that Mil Design Bureau focused on. The basic feature of the twin-engine is the herringbone structure-two TB3-117s are close together, with the main rotor transmission on top, which is the design of the Mi-8. At the same time, the skid landing gear was cancelled and replaced with a retractable front three-point landing gear.

At this time, the designers also considered imitating the American AH-56 Cheyenne’s practice - changing the two-person cockpit to a front-to-back tandem, and making the front gunner’s seat a swivel chair linked to the aircraft gun, so that the line of sight always remains consistent with the shooting direction. However, Mil was still hesitant about the specific aerodynamic shape of the cockpit. In addition, there was the setting of the short wing. Was it simply shortened based on the Mi-6, or was it slightly anhedral and the full length remained unchanged? Would the anti-tank missiles be hung under the short wing or attached to the sides of the front fuselage? In short, a large number of models were finally pushed to the Ministry of National Defense, and they first eliminated the "least pleasing" design, and then carefully compared the remaining ones. The Phalanx anti-tank helicopter was unpopular and met with strong resistance. It should be equipped with assault missiles (which were still under development at the time). Some military personnel believed that the 23mm aircraft gun was excessive firepower and that it would be enough to use a rotary machine gun like the Americans, but of course the caliber should be changed to 12.7mm.

Starting in a hurry

In short, buyers have the right to praise or criticize. Mil finally received a formal R&D contract on May 6, 1968. The general requirements were a maximum speed of no less than 200 to 217 miles per hour, a hovering altitude of 4,900 to 6,560 feet (even in high temperature environments), and a maximum load of more than 1.9 tons. The helicopter must also have good maneuverability and power margin to meet the needs of air combat with enemy helicopters, and the onboard weapons can be accurately fired in a stationary or flying state. The B-24 project was officially launched in August 1968 with Mikhail Mil as director. The first batch of prototypes was put into intensive construction. Two years later, Mikhail died of illness and was replaced by Marat Teshchenko as project director. The specific research and development work was in charge of Deputy Chief Designer Kuznetsov, who was also one of the most experienced helicopter designers in the Soviet Union. The chief designer was Olshevitz, while Sernov and Smosnov were responsible for the test flight.

The full-scale prototype was completed and submitted to government representatives in February 1969. In order to catch up with the progress, the design bureau did everything possible to use the technology that had been verified on the Mi-8 and Mi-14, especially the rotor, tail rotor, power and transmission system. The use of mature parts greatly accelerated the pace of development. Of course, the power requirement of the B-24 is higher than that of the Mi-8, so the latter’s TB2-117 cannot be copied, and an improved design must be made, so the TB3-117 came into being. The engine cannot start by itself, and an A-9B auxiliary turbine (located between the two engines) must be installed. The standard power of TB3-117 is 1,700 horsepower. In the case of a single engine failure, the other short-term emergency power reaches 2,200 horsepower. However, it encountered many problems at the beginning. First of all, the performance was seriously unstable and the combination with the fuselage was not ideal. Test pilot Germain Alfiolov, who was interviewed several years later, revealed that the working life of TB3-117 on the prototype was only 2 hours! Every time he sat in the cockpit, Alfiolov didn’t know what would happen. The engine was often in a state of exhaustion, sometimes slowing down very slowly, and sometimes "turbulent"

During that time, the mechanics were very busy all day, but the problems were finally solved step by step, and the research and development steps were also accelerating, although the onboard weapons and optoelectronic equipment were too complicated due to frequent intervention from superiors. Once, when Mil’s representative was reporting to the Minister of Aviation Construction, Demontiev, the minister suddenly interrupted the representative’s speech and asked why many subsystems had to be rebuilt from scratch, when some sensors and navigation equipment were already available. The Su-24’s Jaguar system and the Tu-22’s KIC-53 system were all ready-made and easy-to-use products! There may be cases of duplicate investment, but armed helicopters are different from ordinary platforms after all. Some equipment does need to be tailor-made, but at that time, the guiding ideology of large-scale production was overwhelming, and the more factories produced, the more favorable the products were. Therefore, the research and development units and manufacturers designated by the minister only followed orders to produce, and would not make any improvements based on the special requirements of the Mi-24. Therefore, Mil had to polish many details himself. Some aviation commentators believed that Demontiev’s snap decision caused the project to be delayed for many years. In fact, there were more difficulties than these, and the weapons were also behind schedule.

The Moscow Helicopter Factory completed a total of two B-24 prototypes for flight tests, code-named Product 240, and then completed the construction of 10 pre-production models (5 each) together with Arsenyev’s 116th Factory (located in western Siberia). The factory test began on September 15, 1969. Initially, several tethered launches were carried out. On the fourth day, the real test flight began. The test pilot was Germain Alfiolov. In June 1970, the prototype was sent for national testing, which lasted about half a year. The flight plan was very tight, and the flight data obtained verified the success of the design. The only worrying thing is that some structural components and functional equipment have a short lifespan, and the vibration is more serious in certain flight conditions. The technicians then replaced steel with titanium for some high-load parts. As for the vibration, they could only endure it and gradually got used to it. At least it was quieter than the Mi-8.

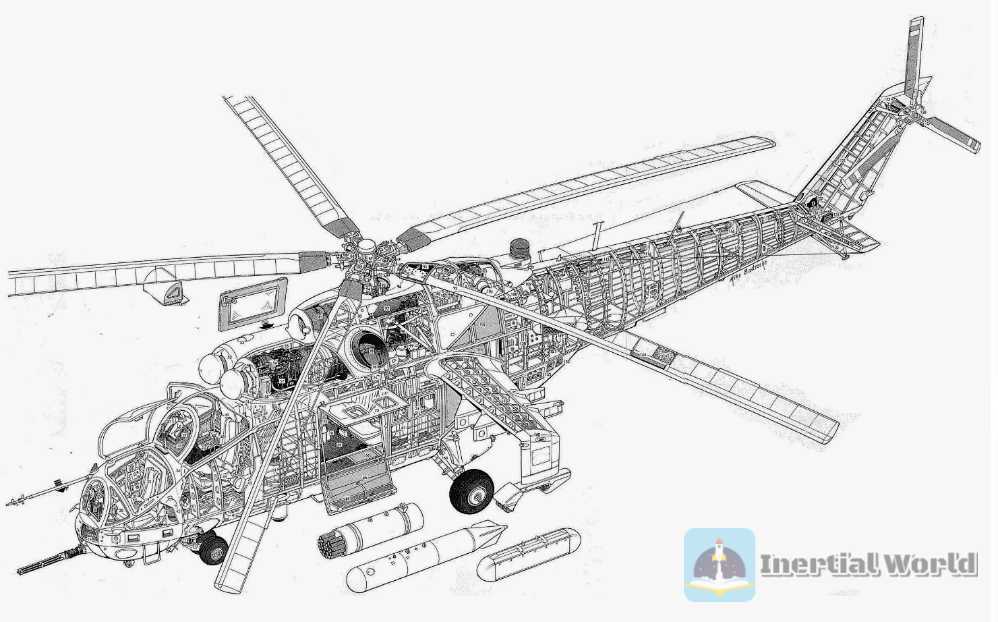

Appearance features and basic configuration

The aircraft retains the classic aerodynamic features of the Mi-8: a five-blade rotor system and a three-blade tail rotor. To ensure flight stability and improve the accuracy of airborne weapon launch, the main rotor is tilted 2.3° to the right relative to the longitudinal axis. The rotor is equipped with a flap hinge and a swing hinge, as well as a shock absorber and an automatically adjustable flap limiter. The rotor disc rotates clockwise when viewed from above, which is exactly the opposite of Western helicopters. The aluminum alloy blades are segmented honeycomb structures (a total of 18 segments), and the blade beams are filled with compressed air. The system is heated and de-iced by electric means, and can withstand direct attacks from small-caliber weapons. The main rotor hub is equipped with a blade brake to prevent the blades from rotating for too long when the engine is stopped or disconnected. The tail rotor is mainly made of fiberglass material, which bears 1/3 of the torque balance during flight. It was originally installed on the right side of the vertical tail and served as a propulsion propeller. Starting from the last batch of Mi-24A, it was changed to the left side and turned in the opposite direction, becoming a pull-in propeller in the main rotor airflow, which greatly improved efficiency. One pre-production model also completed a special transformation in 1975, becoming an 8-blade counter-rotating ducted tail rotor, and also cancelled the short wing, but it was soon discovered that it was not suitable for the Mi-24, and future research and development came to an abrupt end. The bottom of the tail beam is an anti-collision and skid resistant structure, which consists of three short metal columns with intersecting ends. On both sides of the root of the vertical tail are horizontal tails, which are used to maintain longitudinal stability and achieve synchronous control through the collective pitch rod.

The all-metal semi-monocoque box-shaped fuselage is nothing special, but for combat effectiveness considerations, the Mi-24 adopts a streamlined design with better aerodynamic performance than the Mi-8, which is conducive to reducing flight resistance, and fixed short wings are set for the purpose of mounting weapons. One of its functions is to share the load of the main rotor so that the latter does not have too much pressure. Under different speed conditions, the lift generated by the short wing is also different, and the maximum value can reach 25%. The vertical tail area is 10.75 square meters, and the cross-section is asymmetrical. This design can relieve the tail rotor pressure at high speeds and can generate 2/3 of the required torsional torque. The tail beam, which smoothly transitions with the fuselage, is much thicker than the Mi-8, with the upper end extending horizontally and the lower side gradually tilting upward to the end. A very unique feature is that the Mi-24’s central fuselage, power and transmission devices also have a certain right tilt, which can greatly reduce side slip and tilt when flying forward, and is also conducive to weapon guidance. The three-redundant hydraulic system can greatly improve the survivability performance in the state of battle damage. At the same time, the B-24 is also the first helicopter in the Soviet Union to use retractable landing gear. The adjustable parallel double front wheels are equipped with hydraulic shock-absorbing struts, but there are no brakes and they cannot be completely retracted under the fuselage. In this way, in the event of a crash, it can act as a buffer pad, and the single-wheel main landing gear with independent brakes can be completely retracted on both sides of the belly, but the door size is large and slightly bulging.

The assault missiles and Yak-B weapon systems for the new aircraft have not yet been finalized and put into production. The prototype is equipped with a relatively mature and reliable system: the K4B weapon complex on the Mi-4 and Mi-8. The nose is equipped with a HyB-1 weapon station, equipped with an Afanasyev 12.7mm machine gun. The missile part is the 9M17M "Phalanx"-M system, which requires the gunner to manually guide the three-point method. The optical sight 9Шa121 has a maximum magnification of 8 times, and the radio equipment transmits the control signal to the missile receiver. A y 6-32 rocket pod can be hung on the weapon rack to launch C-5 rockets or 100 kg and 250 kg conventional bombs. The storage racks on each side can also carry 500 kg of bombs or incendiary bombs. Bombs are dropped through the OPB-1 bombing sight in the cockpit, while rocket launches rely on the ПKB sight (pilot is responsible). Most of the avionics and radio equipment are located in the rear fuselage and tail beam. The B-24 is equipped with the ByAП-1 autopilot and the corresponding CAy-B-24 navigation system, as well as the ДИCC-15 Doppler navigation system. The latter, combined with the radar altimeter, can determine the exact position of the helicopter and mark it on the cockpit map.

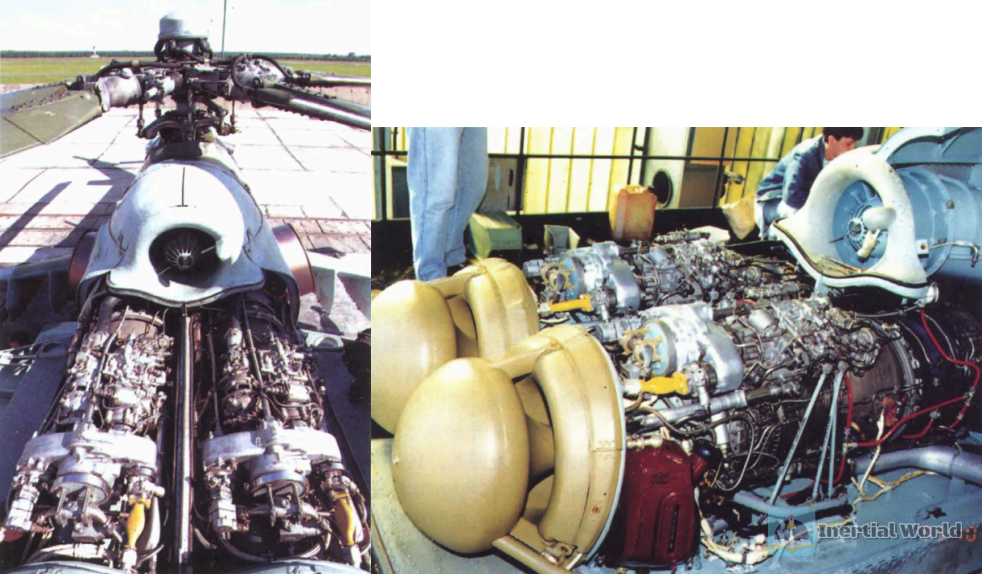

The air-cooled engine TB3-117 (the letter TB stands for the turboshaft) is initially divided into four sub-models: 0/1/2/3. The total length is about 2.06 meters, the width is about 0.63 meters, and the height is about 0.71 meters. Depending on the model, the weight ranges from 285 to 295 kilograms, the fuel consumption rate is between 0.21 and 0.227 kilograms per horsepower hour, and the take-off power ranges from 2000 to 2500 horsepower. Since 1975, a dust cover has been installed to block the entry of foreign objects. The air intake is also equipped with an angle-adjustable guide vane. At the rear is a 12-stage axial compressor for air intake supercharging. The first 4-stage guide vane can be automatically adjusted according to the operating conditions. In response to changes in pressure and airflow conditions, the number of blades at each stage increases gradually. Further back is an annular combustion chamber with 12 nozzles, where fuel and air are fully mixed and burned. The front end is a diffuser to ensure a constant intake speed. Air is blown into the combustion pipe at the rear through 12 nozzles. The jet sprays fuel into the airflow to produce a combustible-oil mixture for ignition and combustion. Part of the airflow bypasses the combustion pipe for cooling. There are multiple openings at the other end of the combustion pipe for ventilation, the purpose of which is to ensure a constant oxygen supply. Of course, as a supporting measure, the combustion area of the combustion pipe also needs to be adequately supplied with fuel. The 5 self-sealed fuel tanks can hold 2,123 liters of fuel. At the same time, in order to increase the range, two auxiliary fuel tanks can also be set up in the cargo hold, increasing the total amount by 1,627 liters.

In terms of flight performance, the biggest problem of the B-24 in the early days was the so-called Dutch roll, that is, the yaw and roll vibrations came together. From the outside, the aircraft looked like a staggering drunkard. In order to maintain balance, the pilot had to work hard to make various compensatory movements. Without an autopilot, the B-24 would roll more than 120 degrees, and the fundamental solution to the problem was to redesign the short wings, that is, to replace the original straight short wings of the Mi-6 with short wings with an anhedral angle. It is located above the cargo hold on the rear side of the fuselage, with an installation angle of 19°, a 12° anhedral angle on the lateral side, and an 8° swept leading edge. The lift-enhancing performance of the short wing will also change with different speeds, with a maximum value of 25%, which greatly reduces the burden on the rotor, prolongs the life of the blades, and makes the Mi-24 more maneuverable. The all-metal cantilever short wing has nine wing spars, and two huge racks on each side can carry a total of 3,300 pounds (1,498 kilograms) of weapons - each inner rack carries 1,100 pounds, and each outer rack carries 550 pounds, including free-fall bombs, incendiary bomb boxes, cluster bombs, gun bays, and unguided rockets. The designers were worried that the tail flame of the anti-tank missile would spray onto the fuselage, so they placed the launcher at the tip of the short wing. In addition, unguided rockets are also an unsafe factor. If they are launched during a large maneuver flight, they may also damage the carrier aircraft. In the subsequent weapon test phase, Mil designers found that the most troublesome problem was that the Rainbow-Φ sight was too large and difficult to fit into the cockpit, and the Yak-5 machine gun with the yCIy-24 turret seemed to be more cumbersome than originally expected. These seemed to be unable to be changed, and the problem could only be solved by lengthening the fuselage.

Not satisfactory

In fact, the new helicopter was put into production at the 116th Factory in Arsenyev in late 1970 before the completion of the national flight test. It was delivered to the troops the following year with the work code 245 and the corresponding military number Mi-24A. However, the design bureau and the Ministry of Defense’s plan to use it as a purely transitional model fell through, because the progress of the weapon system was behind schedule, and the Mi-24A could only fill in first. The first batch was delivered to the military helicopter training center in Voronezh, and among the combat troops, the first to receive the Mi-24A was Haicuang, which is also the base closest to the Arsenyev factory. Since the ground support force of the military helicopter was relatively weak at the time, this made it easier to repair problems at any time, and it was also more convenient to receive relevant training and technical upgrades. By 1974, when production was discontinued, a total of about 240 aircraft had been produced. On the one hand, the pilots of the army were pleasantly surprised by its excellent maneuverability and regarded flying the Mi-24 as their life dream, but on the other hand, they felt disappointed with the weapon system.

In fact, from the perspective of onboard weapons, the Mi-24A and the Mi-4M are no different, and are even slightly inferior to the Mi-8. It can only carry four y6-32 rocket pods and six "CIW"-M anti-tank missiles, while the Mi-8T6 can carry six rocket pods and six missiles. It should be pointed out here that the yB-32 is generally used to launch C-5 series unguided rockets. Its history can be traced back to the early 1950s. It is mainly used to deal with Western nuclear bombers. It was first used on the MiG-19 fighter. The pilot used the ПyC-32 launcher to achieve rate of fire control. Later, as air-to-air missile technology matured, C-5 rockets were used for ground attacks. At this time, two launch nests with yB-16 and y 6-32 tubes were developed, with five salvo modes of 4, 8, 16, 32 and 64 rounds. Although the Phalanx-M, which entered service in 1967, had a longer range than the Infant, its accuracy and reliability were far from ideal, with a hit probability of only about 30%. The performance of the 12.7mm machine gun was very stable, but too stable. The low firing rate was worrying, and its range was too small, and the aiming system was also very primitive. Of course, the cockpit layout was also criticized a lot. The armor protection was better than nothing, giving people a sense of insecurity. The seats were staggered front and back but not pulled apart in height. As a result, both the pilot and the gunner had a large blind spot, and on a sunny day it was like sitting in a steamer, and it didn’t take long for them to get hot and sweat all over.

The pilots also have to adapt to one thing: the new helicopter landing gear is retractable, so you must remember to lower the landing gear before landing, otherwise you will sit on the ground and sparks will fly. It was also found that the early version of the warning had many shortcomings during use, and the service life was also short (generally only 100 flight hours). After upgrading and improvement, it gradually increased to 300 hours and 750 hours. When completing certain maneuvering flights, the tail rotor will also fall off the chain, mainly when encountering strong side winds, the directional stability will be significantly reduced. Later, the tail beam was modified, the tail rotor was moved from the right to the left and the rotation direction was adjusted, and the coupling with the downwash airflow of the main blades improved the aerodynamic efficiency. The new version was shipped in 1973, but the troops that had been equipped did not return to the factory for modification. In fact, the Americans encountered similar problems when they were working on the AH-1G, and the corresponding measures taken were also similar-moving the tail rotor from a dragging propeller to a thruster propeller, but the switching direction was exactly the opposite of the Mi-24A, because the tail rotors of the two had opposite rotation directions. During this period, a Mi-24F (245M) with a tail rotor replaced was added with 7 reinforcement ribs on the left rear fuselage, and the position of the enemy identification antenna was adjusted. The auxiliary power system nozzle was lengthened and tilted downward.

Despite many shortcomings, in order to demonstrate the country’s aviation technology strength, the Ministry of National Defense still gave the Mil Design Bureau the task of breaking the flight record with the Mi-24 in 1975. The Mi-24 specifically used for breaking the record was called A-10. First of all, weight loss should be implemented: all equipment that is not absolutely necessary should be removed, armor, weapons, related sensors and avionics equipment should not be removed, and even the short wings should be cut off. The only thing that has increased instead of decreased is the engine power, which has been replaced with a more powerful modification. In addition, the rotor system has also been specially modified for breaking the record. Because the Mi-24 was still strictly confidential at the time, the Mi-24 name did not appear in the file when it was reported to the International Aeronautical Federation. The pilot was sitting in the cockpit of a Mi-8 helicopter in the public photo.

What surprised the outside world even more was that the pilots were actually two women: one was engineer test pilot Galina Rastogoeva, and the other was Lyudmila Polyanskaia, who had worked as an Il-18 navigator for Soviet civil aviation. On July 18, 1975, the two piloted the Mi-24 to create the average speed record for female pilots on a 100-kilometer closed route - 334.464 kilometers. Just two weeks later, the two teamed up again and broke the out-of-bounds record for a 500-kilometer closed route with an average speed of 331.023 kilometers per hour, and this achievement broke the gender boundary. After that, the two continued to work hard and broke the 1,000-kilometer route speed record on August 13, with a score of 332.646 kilometers per hour. On August 8, they reached an altitude of 3,000 meters in 2 minutes and 33.5 seconds, and climbed to 6,000 meters in 7 minutes and 43 seconds on August 26. The A-10 record later confirmed by the FAI also included the 15 and 25-kilometer route speed records (368.4 kilometers per hour) set by Gorgun Karapetyan on September 21, 1978, which was not broken until 1986 by the Westland Lynx.

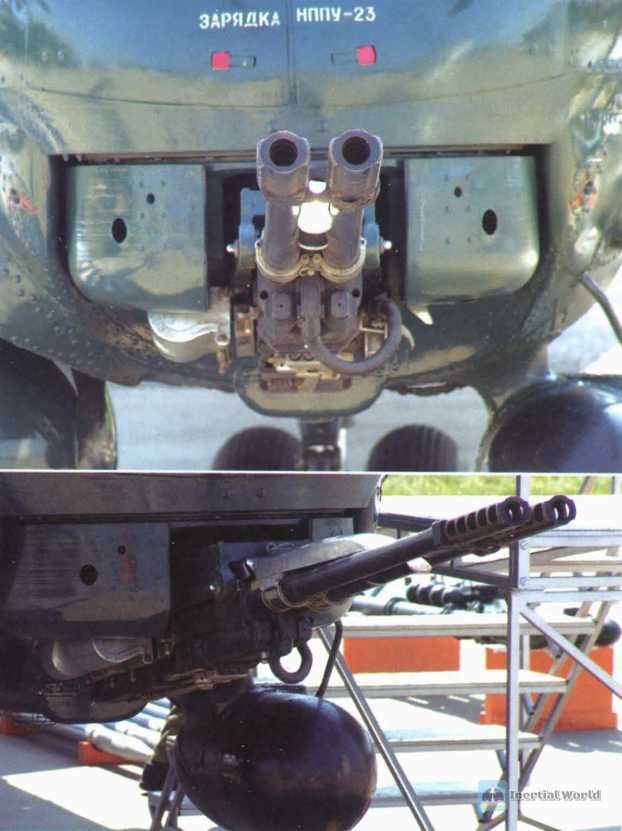

Perhaps because the combination of the Yak-6 machine gun and the Phalanx-ПB missile was late, many Western publications also described the Mi-246 as a transitional model, which is obviously not true. On the contrary, Mikhail regarded it as the first generation of real armed helicopters from the beginning. The prototype was extensively tested between 1971 and 1972, proving that its performance was a great improvement over the Mi-24A, but it was not immediately put into mass production because the Mil Design Bureau was busy testing the basic model to "slim down" (better bulletproof effect). In terms of appearance, the Mi-246 is of course not difficult to distinguish from the Mi-24A. The Yak-5 machine gun turret on its lower jaw is very different from the previous machine gun. The gunner needs to use the KПC-53AB system to complete the aiming. The machine gun can accept a dive angle of 15°, while the maximum angle of the turret is 10°. The angle of attack sensor and pitot tube transmit signals to the CICB-24 analog computer, which gives instructions after completing the settlement and selects the target to be aimed at.

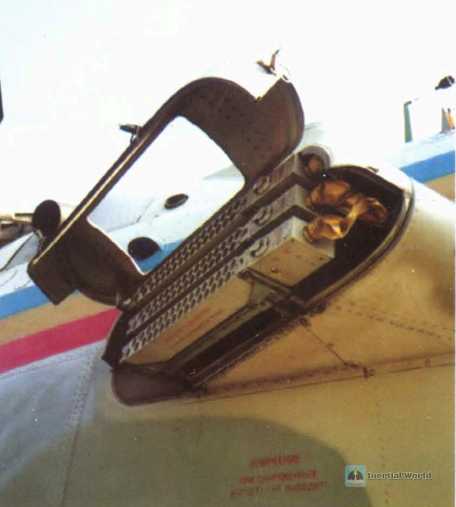

The original cockpit design does have major flaws. Although the interior space is spacious, there is a large visual blind spot, which is particularly fatal to the pilot. In addition, two people sharing the same cabin could be easily killed instantly by a round of ammunition, so the design had to be redesigned, the cockpits were strictly separated front and back along the longitudinal axis, and the height difference was clearly opened, so that the pilot’s vision was no longer blocked by the front seat. Both cockpits were covered with thick armor plates, and the nose armor extended backward to the shoulders of the crew members, which could withstand direct hits from 12.7mm machine gun bullets, creating a safe environment like a steel bathtub. At the same time, the original machine gun ammunition in the cockpit was also moved away (placed under the floor on the right side of the cockpit). In the early summer of 1972, two B-24s equipped with new noses began to be tested. In the future, they would be modified with more advanced anti-tank missiles, which would be in place in 1973. The problem was that this new Strike-B missile did not match the new nose, so the Mi-245 seemed to have no hope of being put into production from the beginning.

After evaluating the initial operating experience, the design bureau introduced a new cockpit front section in 1972. After testing, it was found to be very good. The test pilots all expressed their support without exception. This cockpit has become the classic shape of the Mi-24. This modification was given the code name 242, and the corresponding military model was Mi-24B. At this time, the Air Force was waiting for the delivery of the assault anti-tank missile with the Mi-24. The design bureau also specially allocated a prototype for test firing. Unfortunately, the development of the missile was still delayed, and it was not put into test until 1973. So they could only make a transitional model for emergency use. This was the most important model of the family, the Mi-24. In fact, one of the first batch of Mi-24s shipped was to replace the B-24 to take on the test mission of the assault missile. Soon after, the Mi-24B prototype was also used to test missiles, which lasted for about two years and ended in 1975. Then the Arsenyev and Rostov factories began to put the Mi-24B into serial production.

The tandem cockpit has a significant height difference between the front and rear, and can withstand an outside temperature between -50°C and +37°C. The unique feature is that it is similar to a double bubble hatch design, with round frame windshields, curved ceilings and side windows in the front and rear cabins. The design bureau jokingly calls it a "balcony" because the large area of spherical glass is similar to a greenhouse ceiling, which can quickly accumulate sunlight and make the interior as hot as a furnace. In an emergency, the cockpit can be completely closed. After all the windows are closed, an overpressure state is formed inside, which can effectively isolate radioactive dust and toxic gases from entering. The gas brought by the seventh stage compressor of the engine is filtered and introduced into the cabin. In addition to air conditioning, there are small three-leaf rubber fans above the front and rear seats, and the seats themselves have a certain bulletproof effect.

The pilot in the back seat enters and exits from the large door that opens from the right to the back. The seat is slightly to the left. He is responsible for the navigation of the helicopter. If necessary, he can also fire rockets or operate machine guns, but the weapons must be fixed in the middle. The pilot has a full set of flight and navigation instruments in front of him (there were no digital indicators in the early days), mainly APK-15M and APK-2y radio compasses. Most of the VHF and shortwave radios are also in this cabin. In the center of the large instrument panel is a cross mark showing the actual position of the helicopter. The instrument panel is connected to the Doppler navigation system. If necessary, you can also keep in touch with the front seat through the CIy-8 system, and you can also issue an alarm through the PИ-65 sound intelligence system. If the flight parameters are abnormal, such as the maximum speed exceeds the value, the angle of attack or the landing speed is too large, the device will also "beep". The crew heard a delicate female voice pre-stored in the system, which was said to be a recording of a famous announcer at the time. The pilots called this system "Natasha" or "Nagging Nadia"

The front passenger compartment is equipped with a gunner (the instruments in this compartment are incomplete on the prototype), and there is a thick bulletproof glass on the side above the cabin door. Although head protection was considered at the time, bulletproof vests did not officially appear until a few years later, during the Afghan War. In order to adapt to flying at an altitude of more than 3,000 meters, the crew members were equipped with oxygen masks. The main task of the gunner is to search, lock and identify the target, and "solve the problem" with machine guns, bombs or missiles. After the improved design, the gunner’s compartment not only has a joystick and a collective pitch lever, but also a pedal, so that the gunner can take over when the pilot encounters an accident or cannot control it. A simple bench is set up on the narrow aisle leading to the middle fuselage, which is used to arrange the third crew member, usually acting as a random engineer, and can also replace the two people in front in an emergency.

The most unique point is that a person/cargo cabin is set up behind the bench, which can also create a closed overpressure environment like the cockpit. The cabin can hold up to nearly 2 tons of cargo, or 8 fully armed soldiers. The seats are set in the middle, and the 8 people face the outside of the cabin back to back. Due to the small net height, adults cannot stand up straight. If no armed soldiers are carried, 4 wounded soldiers in a lying position can also be carried. The door is equipped with bulletproof armor that can resist small-caliber ammunition. It is divided into upper and lower sections. The lower half is equipped with a foot pedal for quick boarding and a manual unlocking device. There is a window on the door that can be opened to meet the needs of external shooting. The window also has a bracket for installing machine guns. The AK-47 gun family is also equipped with a barrel cleaning machine, which is connected to the machine gun’s receiver cover and discharges gunpowder exhaust gas through a movable tube. According to later experience, the side of the cabin, especially the glass window, is a soft spot and is easily attacked by the opponent. Therefore, the random engineer has an additional task to operate the ПK machine gun on the side to shoot at the enemy who shows his head.

At first, the standard paint of the Air Force was a light green background with irregular blocks of medium green, some of which were similar to clover, and the bottom of the fuselage was a single sky blue. Later, it became a sandy yellow background with brown spots, and the belly was light gray-blue. It was obviously a change made for the battlefield environment. There is also a saying that it was made by two different manufacturers. As time goes by, the paint will slowly wear and fade, and finally reveal the metal base color. The tactical number was originally located at the rear of the fuselage, but soon it was moved to the tail beam. It was usually written in bright yellow, red and blue paint, and a few were written in white. Sometimes, for easy reading, the number would be written on the cabin window. Later models would generally be painted on the air inlet filter or de-icer, with numbers indicating the squadron they belonged to.

A more popular simplified version

The Ministry of National Defense approved the entry of the Mi-24B into the armed forces on March 29, 1976, the same day that the Mi-24D was approved for service. Although the latter had already been equipped in large numbers, the army had been reluctant to officially accept it before, and did not point out any shortcomings in performance. The outside world speculated that it might be for the practice of the Mi-24B to enter service no later than the -24. From the appearance, it is difficult to distinguish the two. The aerodynamic performance is comparable. In fact, the internal equipment is also roughly similar. The main difference is that the Mi-24B is equipped with more advanced assault missiles, the wingtip launch rails are completely different, and the outer racks can also be used for missile launches, so each Mi-24 can carry 8 anti-tank missiles. The original Rainbow-Ф guidance system was upgraded to the Rainbow-Ш, which is dedicated to assault missiles. The latter is incompatible with the earlier missiles. In terms of anti-tank operations, the Mi-24B is indeed significantly superior to the Mi-24. Another difference is that the Mi-24B can hang a pair of auxiliary fuel tanks (up to 446 liters on each side) under the short wings, which can free up space in the rear cabin for transporting troops and other equipment. Of course, the option of arranging fuel tanks in the cabin is still retained. The Mi-24 redesigned its nose according to the Mi-24B, and still used the weapon system of the Mi-246. The prototype was modified from the existing Mi-245 (some information says it was modified from the Mi-24A). The test flight started in late summer of 1972 and lasted until the fall of 1974. Compared with the later Mi-24, the two prototypes retained the original layout of the tail rotor on the right side, and the rest of the parts were almost the same.

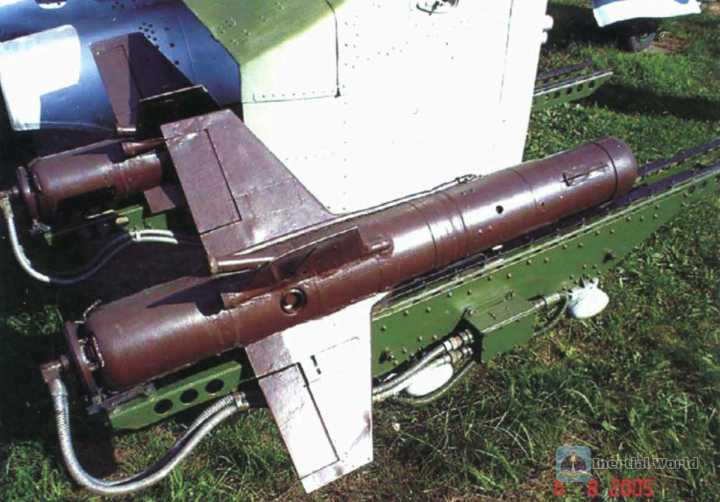

The 9M114 Assault-B, which is specially designed for helicopters, was officially equipped to the troops on March 28, 1976. It also has a land-based launch version, all with aluminum or reinforced plastic sealed storage-launch tubes, which are much more advanced than the early "Phalanx" bare-handed. The total weight of the missile and the launch tube is about 46 kilograms, the weight of the missile itself is about 32 kilograms, the diameter of the missile body is 127 mm, the wings and stabilizer tail are folded for storage, and the latter is about 467 mm when unfolded. The front end of the missile is a hollow charge warhead, piezoelectric device and insurance, guidance unit and power supply equipment, as well as a control system (including brakes), followed by an initial velocity and endurance engine, and an equipment compartment with a radio receiver and infrared energy. The airborne launch also adds a disposable booster at the end. The missile can accelerate from 530 meters per second to 2481 meters per second in just 2 seconds after launch. After that, the endurance engine starts, allowing the missile to maintain this speed for about 5 seconds. The missile then relies on its large kinetic energy to fly, and even at the maximum range, it still maintains supersonic speed.

The operator always needs to keep the target in the crosshairs of the sight during the flight of the missile, and use the infrared direction finder to obtain the error between the missile’s instant position and the aiming line. The digital computer generates the corresponding guidance instructions and transmits them to the receiver on the missile. The distance value has a great influence on the flight profile of the missile. If it is a close target, the missile can quickly get on the "right track" and hit it accurately. If the distance is far, it must first fly about 5 meters above the aiming line to prevent the operator’s observation of the target from being interrupted midway or the missile directly hitting the ground. The minimum range of the missile is 396 meters and the maximum range is close to 5,000 meters. Tests have shown that the maximum range precision strike target capability is also quite good, and the error can be controlled within 0.6 meters. However, if the distance is far, the enemy identification capability will be affected. In addition, the warhead penetration effect is also directly related to the speed and range. If it is a vertical human shot, it is not a problem to penetrate a single piece of 610 mm steel armor. Of course, it is very difficult to pry open the frontal armor of the main battle tank at that time.

It needs to be mentioned here that before the assault missile was put into service, there was a transitional missile of "Phalanx"-П (9M19П), which was equipped with a semi-automatic command line aiming device, which was half a generation ahead of the previous "Phalanx"-M. The missile is nearly 1.17 meters long, with a wingspan of 0.676 meters and a launch weight of about 32 kilograms. The head is relatively round and blunt. It is equipped with a hollow charge warhead that can penetrate about 560 mm of homogeneous steel armor at a 90° angle. It has a single-chamber solid fuel propellant at the rear. Like the assault missile, it relies on the sight to aim at the target and always keep it pressed against the crosshairs. At the same time, the infrared direction finder tracks the flight trajectory of the missile, the goniometer calculates the deviation between the actual position of the missile and the aiming line at any time, and the analog computer calculates the amount of adjustment required. The radio command transmitter then issues a correction command. The carrier aircraft can choose to fly forward or hover to launch (the best state is 40~80 meters in altitude), but it requires the joint efforts of two crew members. After pressing the launch button, the missile will fly out 3.5 seconds later, and it will take about 2 seconds to enter the guidance and control area of Rainbow-Ф, and then the carrier aircraft can choose to leave. It can be seen that it is still very troublesome and relies heavily on the skills of the operator. Under ideal conditions, the hit rate can reach 80%.

The earlier C-5 rockets had a high rate of fire but poor accuracy and relatively limited penetration, so they were not up to the task of attacking armored targets. Since the late 1960s, the 80mm rocket has been developed. Its hollow charge warhead is more powerful, has a longer range, has more fragments, and has reduced the number of stabilizing wings to 6. However, the problem with thicker and more powerful rockets is that they pose a potential threat to the carrier, so a special launcher needs to be developed. There are five main types of multi-tube launch nests for C-8, and the main ones suitable for helicopters are 6-8B20A and B-8-10. It was also from the Mi-24B that the new C-8 rocket was gradually delivered and used. According to the difference in the use of the warhead, it is roughly divided into nine types, such as C-8B/БM concrete penetration type, C-8Д/ДM/ДФ fuel air type, C-8M/KOM hollow charge-fragment type, C-8T tandem hollow charge type, etc. In terms of range, C-8ДФ/-8M/-8T and others have reached 6.2 kilometers, while C-8M and -8T can penetrate 400 mm homogeneous steel armor, and C-8B/6M can penetrate 800 mm thick concrete walls. The cluster bomb system (KTMy) used to destroy surface targets was also equipped from this period. The bomb box is a long cone fairing cylinder at the front end, and countless sub-bombs and mines are thrown out through four pneumatic valves and spring devices below. The interval of ammunition throwing can be controlled manually to adapt to quantitative delivery and platform speed differences. The ideal height is generally not more than 1,000 meters, but it should not be lower than 35 meters.

The research and development task of the four-barrel 12.7 mm machine gun equipped as a fixed light weapon was handed over to the Central Design Bureau of Hunting/Sporting Firearms in Tula in 1968, and the previous Afanasyev machine gun was completely abandoned. It is equipped with 12.7x108 mm M30/38 cartridges, the firing rate index is required to reach 4000~5000 rounds/minute, the barrel life is not less than 8000 rounds (maximum 10000 rounds), and the weapon weight is controlled within 30 kg. The chief designer is Peter Gerasimovich Yakushev. After the military approved its development plan, it was given the official number TKB-063. It adopts a gas-operated self-loading design, does not require external drive, is equipped with a split-type belt, and has a very high rate of fire. The biggest drawback is that once the ammunition fails to ignite, it will cause the machine gun to "mute", so a double set of ignition cartridges are specially set up for re-ignition at any time.

The initial design test was officially launched in 1970. The designers found that the barrel life was too short, so they coated the inner lining with a layer of cobalt alloy and reduced the amount of gunpowder in the cartridge. The subsequent TKB-063 test continued until 1971. Unfortunately, the reliability was still not ideal, and it seemed difficult to solve it in a short time. The improved machine gun passed the factory test in September 1972 and 3 were sent for national testing. The ground test lasted for nearly a year until it came to an end in August 1973 and began aircraft testing. The results proved to be quite good, but designers Yakushev and Bolzov were not satisfied. They believed that the machine gun was not powerful enough and the design was too complicated. There would definitely be many problems in actual combat. Each barrel of the TKB-063 has an independent gas piston. Although it performs well individually, it is subject to many restrictions as a whole system, so the structure needs to be greatly improved.

The simplified design of the prototype gun was completed in Tula at the end of 1972. The energy supply device was reduced to 12 parts (originally as many as 88), and only one pneumatic piston was retained. During the shooting process, it moved back and forth between the two air chambers to generate enough energy to provide to the rotating mechanism. The shooting test under different temperature conditions began in May 1973. Shortly thereafter, Yakushev suddenly died and was replaced by his deputy Bolzov. The manufacturer was ready to put it into production at any time. The adjustment and modification of the pneumatic piston and the continuous shooting performance have always been the focus of the work. If everything goes well, there will be no major problems in mass production in July 1974. The finalized aircraft test (on Mi-24B and -24D) lasted from 1975 to 1977. There are two ways of loading, one is the installation of the lower jaw machine gun tower, and the other is the launch of the pod under the short wing. The former can rotate 60° to the left and right, and the pitch angle is between -40° and +20°. Finally, the Soviet Council of Ministers officially accepted the TKB-063 into service in March 1976, and the name was officially changed to 12.7mm Yak-6 (9A624) machine gun. Of course, from the perspective of normal training, the machine gun has good performance, but entering the state of war is another matter.

The main problem is that the barrel is easy to heat up and cause jamming, and sometimes the ammunition will spontaneously ignite in the barrel, and the crew cannot control the shooting state at all. For this reason, many units have stipulated to reduce the amount of ammunition carried, and the base number of 1470 rounds of ammunition is never implemented. Generally, only 400~500 rounds are carried. Many pilots feel very helpless, because the maximum rate of fire of the machine gun exceeds 4000 rounds/minute. In this way, it is finished in a few seconds, and its firepower advantage cannot be exerted at all. The superior stipulated that a single shot could only last half a second, so the machine gun was opened with such a stumbling. In this way, not only was the killing effect poor, but it also frequently jammed, and gunpowder residue easily accumulated in the barrel. Theoretically, the range of the machine gun is close to 1.3 kilometers, but in the Central Asian plateau area, it is only about 950 meters at most, but the accuracy is very good, and the bullet is also powerful. After 1977, the Tula Design Bureau began to develop an improved version of the machine gun in order to improve reliability and service life, but the army seemed to have no interest in this at first. It was not until the outbreak of the war that the military leaders ordered the machine gun to fire at least 750 rounds at a time, and the improvement of the machine gun was actually put on the agenda. In fact, the long-term improvement work thereafter was intermittent, and various chaotic reform measures during this period had a negative impact on military production. It was not until the end of 1987 that the upgraded version of Yak-B was officially announced to be successfully developed, renamed as 12.7mm Yak BI and approved for batch production, and gradually became the standard from the late model of Mi-24B.

From the beginning, the Mi-24 did not consider the problem of air combat. After learning that the United States had invested in related tests, the Soviet side also formulated a similar plan and began to mount the Arrow-2M on the Mi-24B. The missile has a transport-launch tube similar to that of the assault missile and is equipped with quick-release fasteners. There were no problems in the launch test, but the missile has a short range after all, and large-scale installation is not meaningful. After several years, the mass production of the Needle missile put the plan of mounting air-to-air missiles on the Mi-24 back on the agenda, but in fact it was only a small-scale test installation, because the Russian anti-tank missile itself has a certain combat capability and a longer range than the Needle. In fact, before the disintegration of the Soviet Union, several Mi-24s stationed in East Germany tried to install the launch rails of the P-60 missile on the inner side of the short wing. The Mi-24 with this configuration is generally used for border patrols and can intercept foreign aircraft that violate Soviet airspace when necessary. It is said that the 16th Air Force of the East German troops once launched P-60M in combat exercises, but it is frustrating that under the weather conditions in Central Europe, the detection distance of the seeker for the target aircraft does not exceed 1 km, so later only the ground crew had nothing to do and played with it, and it was almost never dressed like this for official flights.

When the Arsenyev factory put the Mi-24 into production in 1973, the older Mi-24A production line was still not closed. Soon after, the 168th Helicopter Factory in Rostov also joined the production of Mi-24. As of 1977, Arsenyev had built a total of about 350 Mi-24Ds, and then switched to Mi-24PC, while the Rostov factory was still producing Mi-24II until 1983 (some say 1986), of course, some of them were for export. The Mi-24 has undergone many improvements during its service. First, a dust filter was installed in front of the engine air intake in 1975. Later, the TB3-117 engine was also upgraded (the export version uses the more powerful -117B). In all the battles it has participated in, the Mi-24D can be regarded as the performance representative of the entire family. It can be said that it has performed well. The pilots of the army like to call it "crocodile" or "beetle", and its standard lake green camouflage is very similar to crocodile skin. Based on the Mi-240,000, the 249 type was also developed, also called the Mi-24Dy trainer. This aircraft has no machine guns and missiles. The instructor in the front cockpit has a full set of flight and navigation instruments, and the equipment of the trainees in the back seat is not much different from the combat type.

The early models were equipped with a camera gun under the pylon, but the Mi-24D was changed to the wingtip. In addition, the CPO-10 "Siren"-3M radar warning receiver was installed on the aircraft, which could detect enemy radars at 44 to 52 kilometers. The four antennas of the device were located on the short wings, each responsible for 1/4 of the lateral arc. Each antenna transmits the collected radar signals to the CIO-10 system, which selects the real threats and displays them on the small indicator in the cockpit. The arc indicator has a simplified picture of the aircraft in the middle, and four small lights on the edge represent different directions. The lights will automatically dim when used at night. When the Mi-24B appeared in the mid-1980s, the previous radar warning receiver was upgraded to the CIO-15 "Belyoza" level, and a similar horn antenna was installed on the rear cabin. The lights were larger and stronger, which could more accurately indicate the initial source of the radar, and determine the altitude (up, down or equal altitude) and signal strength of the radar illumination, and what type of radar it might be. The threat of shoulder-fired missiles had been taken into consideration at the time, and decoy dispensers were installed on both sides of the tail boom. At first, there was a pair, and soon it was increased to two pairs. The control system in the cockpit was also upgraded. A more basic means is to install an infrared jammer, located at the junction of the end of the engine fairing and the tail boom, similar to a pressure whistle, which interferes with the infrared seeker by emitting amplitude modulated light signals. There are conical mirrors above and below the heat generator, and the entire device is surrounded by the so-called modulation grid, which is actually a thin-walled cylinder with a slit. One layer of the grid is fixed, and the other layer rotates around the fixed grid. Its rotation speed also determines the pulse frequency. The system is operated by the gunner in the cabin. After it is turned on, it must be preheated for 5 minutes, and then it can continue to work for up to 2 hours. It needs to cool down for 1 hour after use. Omnidirectional monitoring is of course impossible due to the obstruction of the fuselage. Its horizontal effective coverage angle is 30°~330°, and its pitch coverage range is -30°~+10°. It is particularly effective at certain front angles (2~5 o’clock and 7~10 o’clock), but its rear interference capability is relatively weak. In addition, the system is more susceptible to sunlight and it is difficult to interfere with heat-seeking missiles fired from the front.

This system is officially numbered C09П:B1A, and its alias is Л116B "Spaniard". The Mi-24Bs that have been in service and have not yet been shipped have been modified. To prevent dust, the outside is equipped with a metal cover. The outer surface of the device is coated with ceramic glaze, which can filter visible light to the human eye and only receive infrared waves. In 1984, the focus turned to the engine, and the 9By infrared suppression system was added, which forms a visual barrier in front of the exhaust port and diverts the high-temperature hot air upward, so that it mixes with the rotor airflow and cools down quickly. The device is similar to two boxes, which can inhale cold air from the front and mix it with the high-temperature exhaust gas to form a vortex that is broken up. At first, the Central Institute of Fluid Power evaluated it as having low performance. After continuous improvement, it finally reached a success rate of about 50%. The dual effects of exhaust cooling and vortex can make the imaging effect of the seeker terrible. Although the infrared suppression system installed on the aircraft can only deal with the first generation of infrared missiles, such as Red Eye or Arrow-2, the mixed use of the "Spaniard" system and infrared suppression has greatly improved the battlefield survivability of the Mi-24B. Armor protection and other aspects are also constantly improving until it was discontinued in 1989.

In fact, the Mi-24 B is the most used aircraft of the same type. The two factories have produced more than 1,500 aircraft in total. Many users have also upgraded the Mi-24D to the Mi-24B standard. The first export model corresponding to the Mi-24D is the Mi-25, and the more advanced Mi-24 B also has a corresponding export version, namely the Mi-25. The West began to know the Mi-24D/B aircraft and once gave it the nickname "Hockey", but later changed it to "Doe", which is still used today. At the same time, the Mi-24D is also the modification with the largest export volume. It is not only equipped with the original Warsaw Pact members, but also sold in large quantities to many Asian and African countries, but it was actually outdated before the upgrade. The Mi-25 appeared on the battlefield in Lebanon in 1982, and its performance was extremely eye-catching. A few Syrian Mi-25s actually destroyed more than 90 Israeli armored vehicles, including the most advanced Merkava-1 main battle tank at the time. The West African rebel forces supported by South Africa also experienced the power of the Angolan and Mozambique government armed helicopters at the first time. Even the Sandinista authorities in Nicaragua used the Mi-25 introduced in 1983 to effectively strike the anti-government forces. Unfortunately, after the new regime came to power, this batch of politically incorrect Soviet-style equipment was abandoned early.

The proliferation and competition of nuclear, biological and chemical weapons have made the battlefield dirtier and more dangerous than before. The Soviet Union considered developing a special NBC reconnaissance model based on the Mi-24B, so it launched Project 2462, namely the Mi-24PXP (usually referred to as the Mi-24P). The prototype was shipped at the end of 1978 and officially put into production in 1983, which lasted about six years, but the total number of production is unknown. Some data say 110, and some say it reached 152 or even 160. The aircraft is equipped with various air and soil sample sampling and analysis equipment. The most conspicuous feature is that the small grab on the outer rack replaces the missile rack, so the crew does not need to wear thick chemical protective clothing to collect samples in person. In addition, there is an air bucket on the left side under the cargo hold, which is also an important sign to identify the aircraft. There are two chemical detector workstations in the cabin, which track the collected samples chemically, radioactively and biologically, and the test results can be sent to the ground base station in a timely manner through the data transmission system. In 1986, the Chernobyl nuclear leak occurred, and the Mi-24PXP was transferred to the accident site, hovering over the destroyed nuclear reactor to monitor and collect data. The high radiation environment made it difficult for the crew to bear in the cabin, so they had to leave halfway. All pilots who could fly Mi-24 in the country were transferred to take shifts. In fact, in the late 1980s, the Science and Production Association also used a Mi-24 B to convert it into an ecological survey aircraft, mainly used for marine oil pollution research. The original egg-shaped guidance antenna was retained, and test instruments were hung under the outer side of the short wing.

Battlefield command and artillery observation are also important combat contents of the Army Aviation Force. The purpose is to find out the precise position of the enemy forces, evaluate the power of artillery and multiple rockets, and provide data correction when necessary. The design bureau developed the Mi-24K (No. 201 product) special observation aircraft based on the Mi-24B platform. The suffix K means correction, that is, artillery observation. NATO gave it the code name "Doe" G2. The prototype was also produced in 1979. The batch production lasted for about six years and ended in 1989. The total output is unknown (the minimum number is 92, and the maximum number is 180). The Rainbow system under the nose was replaced by the Iris special optical equipment. Several reconnaissance cameras were set up in the square cabin. The AФA-100 wide-spectrum reconnaissance camera was fixed on the right side of the fuselage, equipped with a 1300 mm telephoto lens. The Iris is part of the Ruta reconnaissance component and is controlled by the operator in the front cabin. There are also optical target identifiers and digital computers. It is said that data can be transmitted in real time. The weapon configuration of this aircraft is similar to that of the Mi-24B, except that it is slightly weaker in terms of missiles. However, no matter how powerful it is, the Mi-24 will not be a universal helicopter. The Mil Design Bureau once made a Mi-24M maritime attack version (No. 247) in 1970, but it was just a perfunctory work. After all, this has always been Kamov’s traditional advantage.

All-round talent

The West calls the first generation of US armed helicopters air gunboats, while the Mi-24 is regarded by the Soviet army as a flying armored personnel carrier. Its tactical concept is not much different from that of the Il-2 during World War II, and the combat environment set is the Central European plains. Many years later, a French pilot who tested the aircraft believed that the Mi-24 was not a purely armed helicopter, but more like a short-distance vertical take-off and landing aircraft with armed landing capabilities, and should be compared with fixed-wing support aircraft such as the A-10 Thunder and Harrier. In fact, the Soviet Union’s own positioning is similar to this. The Mi-24 is the iron broom of the Army Aviation, doing the hard work of the Il-2 attack aircraft during World War II. The first-line targets and tactical deep targets are the primary targets of attack, and at the same time, the main protection of friendly forces is required. This is similar to the responsibilities of the Mi-8TB, except that the Mi-24 "manages more widely" and takes care of a larger battlefield. Main battle tanks, infantry fighting vehicles and various transport vehicles are key targets for elimination. In addition, there are enemy troops on the move, anti-tank teams, artillery units and various missile positions, radar stations and air defense positions. What should we do if we find nuclear weapons? One word - fight!

Preventing the sudden invasion of enemy armored forces is also the key task of the Mi-24. Single or double aircraft select the ambush site in advance, usually in the woods or the back of the town. The helicopter needs to quickly switch from hovering to attack. After the commander observes the enemy’s position and issues a strike order, the helicopter will quickly turn to the next position after launching the first round of strikes and continue to launch the attack, or hover at a low altitude in the standby area waiting for the commander to issue a new order. Launching an ambush in a hovering state can maximize the range of missile weapons and avoid being counterattacked by the opponent’s air defense weapons as much as possible, but this will cause greater vibration of the fuselage, which will have a certain impact on the accuracy of unguided weapons. Only anti-tank missiles can be used in this way. Launching an attack in a level flight state is applicable to all airborne weapons, but it is necessary to maintain an ultra-low altitude to avoid being discovered by the enemy in advance. Before approaching the target, the helicopter suddenly pulls up, launches missiles at an extremely fast speed, and then quickly turns around and leaves. Of course, ultra-low-altitude flight also means that the maximum range of the missile is a waste. Rockets usually have the best strike effect when diving. After the pilot approaches the target, he suddenly pulls up and can strike targets hidden behind bunkers. In addition, the top armor of the tank is relatively weak, and the probability of being penetrated by rockets is also high. However, the dive attack greatly reduces the maximum range and will also completely expose the helicopter to the opponent’s air defense weapons, making it an easy target. Therefore, this tactic is usually adopted after the anti-aircraft guns and surface-to-air missiles are destroyed.

If necessary, the Mi-24 can also complete aerial mine laying, that is, the enemy breaks through the defense line in a certain direction, or uses nuclear weapons to tear a hole. As an emergency plugging measure, the Mi-24 can be sent to quickly lay mines to cause a large number of casualties to the enemy. Aerial mine laying is generally carried out in fan-shaped echelons or groups. According to the characteristics of the mines, the corresponding flight speed and altitude must be strictly maintained to achieve the best mine density. Unlike the previous Mi-8 and Mi-17, which require the help of special equipment, the Mi-24 can achieve the ideal deployment effect by using ready-made airborne cluster weapons, such as KTMy-2. If it doesn’t work, it can be thrown directly down from the side window. The designated minefield must be clearly visible. If necessary, ground troops or security forces helicopters can mark it directly. The fleet that has completed the minelaying will not leave, but will hover over the war zone for a long time to observe the casualties of the enemy and remind friendly forces to avoid it. According to relevant international law, the mine-laying area must be loaded into the archives and aerial photos must be taken. The mine-laying helicopter needs to hand in the information as soon as it returns to the base, and the troops will archive it for cleaning after the war.

When encountering the enemy fighter, it is of course best to actively prevent the opponent from launching an attack, but in most cases it is difficult to achieve. You can only try to reduce the probability of being hit-accelerate the escape, disperse the formation or drop the altitude suddenly. If the enemy aircraft attacks from behind, the pilot must quickly switch from defense to offense. When encountering the enemy aircraft head-on, the Mi-24 can fly in the opposite direction and use the opportunity of sudden drop in altitude to launch a counterattack, forcing the opponent to turn around and leave. When the Mi-24 enters the ultra-low altitude state, the opponent’s pilots can easily lose the target, especially in complex terrain conditions. Modern radars have great difficulty in tracking and locking helicopters flying close to the ground, and there is basically no opportunity to launch air-to-air missiles, even infrared missiles are useless. If the opponent is also a helicopter, the commander will first call for support troops to cover the Mi-24. The Mi-24 in the cover formation can adjust its speed and flight posture in time to create the most favorable attack conditions, and then use similar weapons to shoot down the opponent. In close combat, aircraft cannons and rockets are good choices. The special Arrow-2 has a higher hit rate. From many examples of the Iran-Iraq War, it seems that anti-tank missiles can also achieve good results.

According to the experience of some countries, the first thing to do in helicopter air combat is always to discover the enemy first. Once a single aircraft is confirmed to be an enemy aircraft, it must approach decisively and launch an attack unexpectedly.

When flying in formation, any Mi-24 that finds an enemy aircraft must report to the formation leader immediately, who will quickly determine the enemy’s model and number, battlefield position and flight direction, and whether there are enemy reinforcements. If the attack is confirmed, the leader will first mobilize the fleet to cover the entire formation. The Mi-24, which is the main attacker, will try to use the cover of the sun, or launch an attack from the back hemisphere, limiting the opponent’s field of vision. After completing the attack, the Mi-24 will quickly return to the team, hide in the clouds, or continue to use the cover of the sun to evacuate the battlefield. If an attack fails, you can launch another attack, but if the opponent flees, you must abide by the principle of not chasing the enemy, otherwise it is easy to fall behind. Although as the first generation of dedicated armed helicopters, the Mi-24 is more often compared with the Bell AH-1, but in fact the design ideas of the two are completely different, and the technical parameters are even more different. In terms of size and aerodynamic characteristics, the Mi-24 and Sikorsky’s S-67 "Black Hawk" are more comparable. Of course, the S-67 has a stronger overall streamlined feel, and seems to be more practical than the Mi-24 in some details. However, the many "coincidences" between the two should not be ignored. First, both use a single rotor with five blades, and the short wing length is exaggerated, but one is the outer section upturned, and the other is the drooping wing downturned, and the engine air intakes are close together like a pair of nostrils. More importantly, both the S-67 and the Mi-24 have troop transport cabins in the middle of the fuselage. Unfortunately, the S-67’s cabin can only accommodate 4 people, and the cabin is more closed, leaving only a small observation hole on each side. In terms of flight performance, the two are basically the same. The S-67 engine power is slightly smaller, and the range is not as good as the Mi-24, but the weapon mounting capacity is better.

A beast in the quagmire

Taking advantage of the window of time when the United States had not yet emerged from the shadow of the Vietnam War, the Soviet Union accelerated its pace of external expansion and brazenly invaded Afghanistan in late 1979. The 40th Army quickly overthrew the pro-Western Amin government and supported the puppet regime to come to power, but the resistance forces relied on the continuous plateaus and mountains to engage in long-term negotiations with the Soviet army, and repeatedly brought heavy casualties to the latter. Among the 110 helicopters sent by the Soviet army at the beginning of the war, there were 90 Mi-8s, and a small number of Mi-6 and Mi-2 helicopters. There were only 6 Mi-24A helicopters for cover. Of course, there was no problem in launching a blitzkrieg to capture the areas around the capital, but this amount of troops was not enough for subsequent wars. The Mi-24A had weak armor and often suffered in front of the guerrillas. So in February 1980, the Soviet army sent a regiment of 40 Mi-24D aircraft to Afghanistan.

This time, the Afghans were a little overwhelmed. The Mi-24’s armor was too strong, and all kinds of light weapons could basically not hit it. The bombs, rockets and machine gun bullets that fell from the sky also made the ground armed forces unable to raise their heads. The four-barrel machine gun firepower was extremely fierce, and it could instantly break a vehicle with weak armor into two pieces. The Afghan guerrillas cursed the aircraft as a "devil’s chariot", but the Soviet ground forces also needed to be careful. It was barely safe to stay at least 300 meters away from the machine gun. It was best to hide 2 kilometers away when bombs fell. The Mi-24D can attack alone, or in pairs or even in groups of several aircraft. In addition to covering ground personnel, it can also actively "hunt and kill" the enemy, or patrol in a designated area, and destroy suspicious targets immediately once they are found. The guerrillas gradually discovered that the high-altitude performance of the Mi-24 II was obviously weak, and its maneuverability was greatly reduced; the pilots had no experience in plateau combat, and in fact, the Mi-24D itself was difficult to fly over high mountains, which resulted in about 21 Mi-24II crashes due to various accidents within a year. But soon the Soviet army replaced the helicopters with more powerful engines, and the pilots received intensive training for plateau flights, and the number of accidents in the following year dropped to only 5.

It is far from enough to improve flight safety. The Afghans got many Soviet-made 12.7mm DShK machine guns, which were very powerful and shot down many Soviet Mi-24Ds, causing the Army Aviation helicopters to not dare to stay in the middle and low altitudes for a long time. However, in front of the Afghan guerrillas who mainly used light weapons, the Soviet Army Aviation still took a clear initiative, and air-to-ground support and free hunting operations have been advancing in an orderly manner. The guerrillas stopped confronting the Soviets head-on and attacked from the side. The Soviets quickly equipped the Mi-24 with ⅡK heavy machine guns to fire at any suspicious targets on both sides during flight. The guerrillas began to attack the Soviet communication lines again, sending lone wolf snipers to sneak attack Soviet soldiers, while stepping up the laying of mines and roadside bombs, or ambushing on the routes that the Soviet convoys must pass. Soon the Mi-24Ⅱ was assigned a new task to ensure the safety of the convoy. They were responsible for cruising along the highway and approaching and annihilating the enemy as soon as they were found. But the biggest problem was that the rugged mountain roads caused the convoy to move too slowly (the average speed was less than 20 kilometers per hour), which often exceeded the endurance limit of the Mi-24Ⅱ. In desperation, the Soviets set up multiple temporary landing and take-off fields near the highway, which were so-called mobile supply points, to provide fuel or ammunition to the Mi-24D that had been flying for a period of time. In addition to being transported by helicopter, a large part of these supplies were provided by the convoys they protected.

Escorting the convoy is important, but it also takes up a lot of energy from the Army Aviation. A more efficient combat mode is to cover the airborne troops deep behind enemy lines, which is also a tactic often adopted by the Americans in the Vietnam battlefield. There are more than 60 Mi-24s that undertake this task. The first thing they have to do is to pull out the enemy’s air defense nails. Various precision-guided weapons can play their maximum effectiveness, leaving the Afghan armed anti-aircraft artillery helpless. In addition, anti-tank missiles can also destroy the enemy’s reinforced fortifications and bunkers, but generally hollow charge warheads are not used, but fuel-air warheads are used instead. After clearing all possible threats, the Mi-24 began to use rockets to open up landing sites. The fierce rain of bullets made the opponent unable to raise their heads, and then bombs were used to expand the results. At first, free-fall bombs were mostly used. From August 1980, fuel-air bombs were used. Of course, the power is very considerable. Afghans call it "little atomic bomb", but it is not always effective. Once the battlefield is cleared, transport helicopters will rush in to complete the paratrooper delivery as quickly as possible. During this process, the Mi-24 fleet will fly overhead to search for and destroy hidden enemy forces until the parachute drop is completed and the last transport helicopter leaves.

In short, in the first two years of the war, the Mi-24 was basically smooth sailing on the battlefield, and there were no special problems that made this "devil tank" feel headache. However, the situation changed in 1982. In this year, the Sixth Middle East War broke out. Israel seized a large number of Arrow-2 shoulder-fired missiles on the battlefield and handed them over to the United States, which then gave them to the Afghan anti-government forces. Although the guerrillas had not received special training before, they still killed many Soviet helicopters. The Soviet army continued to increase anti-jamming measures and installed infrared suppression systems for the engines (see above), which were still very effective against Arrow-2 and American-made FIM-43 Red Eye. In 1984, the Reagan administration provided the guerrillas with FIM-92 Stinger missiles, which the guerrillas used to attack any air targets, and low-flying helicopters became their main prey. What is troubling is that this missile is completely immune to Soviet jamming bombs, and overnight it became the mortal enemy of the Mi-24, and the Soviet army was at a loss. So the Soviet Union sent special forces to seize a batch of Stinger missiles through a surprise attack, and sent them to the Soviet Union for experts to conduct technical analysis, and soon found a response strategy.

Usually, there will be two Mi-24 aircraft on alert above the airport, and they must meet with the civil aircraft passing by at high altitude in time, first flanking the left and right and then descending vertically to block the fuselage, and during this period they will continue to "throw fireworks". If an enemy missile is found to be fired, the Mi-24 must kill it at all costs. If it is an unidentified flying object, it must lie in front to "block the bullet", which has happened many times. In most cases, the "bodyguard" can successfully complete the task, but in the first half of 1987, a large number of Stinger missiles poured into Afghanistan, and the situation suddenly became serious. In just a few months, the number of Soviet armed helicopters lost exceeded the total number of all previous years since the outbreak of the war. Fortunately, in the second half of the year, the Soviet infrared jammer was finally put into use. With the combined effect of the infrared suppression system, the hit rate of the Stinger dropped significantly (only 3 Mi-24s were shot down by missiles in half a year), and a total of 6 were lost in the following two years. Moreover, in actual combat, the Soviet army slowly figured out a way for the Mi-24 and Mi-17 to work together to deal with the Stinger - the Mi-24 led the way and the Mi-17 was the rear guard and escorted from the flank.