After the end of World War II, gun designers had a very mature understanding and cognition of machine guns. At this time, air-cooled machine guns can work well even under high-rate conditions, and the tactical application research of machine guns has become relatively mature and has been verified by war. At the same time, with the continuous development of science and technology, machine guns have become smaller and lighter. From the Vietnam War to the present, the U.S. military’s machine gun equipment system and product performance have become increasingly perfect, and once again led the development trend of machine guns in the world.

M60 general-purpose machine gun (1957)

After the end of World War II, the U.S. military’s various branches of the military had a very strong demand for new machine guns, and at the same time put forward higher requirements. The new machine gun must not only be lighter and more convenient for infantry to use, but also be able to fire in a fixed position to complete more mission requirements. In order to achieve these functions, the United States began research on the M60 general-purpose machine gun in the late 1940s. The M60 general-purpose machine gun was designed based on the captured German FG42 paratrooper machine gun and MG42 general-purpose machine gun, while absorbing the advantages of the M1941 Johnson light machine gun.

The bolt rotary structure used by the FG42 was improved from the American Lewis light machine gun, while the overall layout, machine head and piston gas system of the M60 general-purpose machine gun were borrowed from the FG42 paratrooper machine gun.

The MG42 general-purpose machine gun was called "Hitler’s chainsaw" by American soldiers due to its abnormal firing rate and unique sound when shooting, which frightened American soldiers. The belt feeding system and feeding cover of the M60 general-purpose machine gun directly followed the design of the MG42.

A M60 general-purpose machine gun on the deck of the USS Theodore Roosevelt in 2006

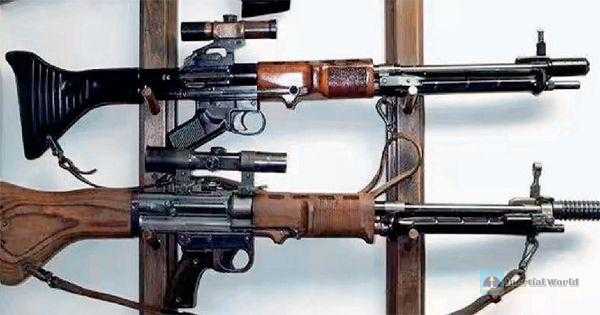

German FG42 paratrooper machine gun, the upper one is an early model, the lower one is a later model, both equipped with optical sights

A close-up of the Lewis machine gun bolt structure, which relies on the guide column at the tail of the gas piston to work with the curved groove on the bolt

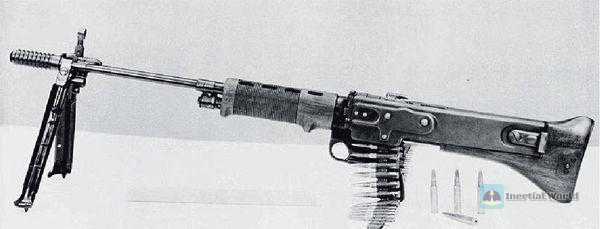

The FG42 paratrooper machine gun exploded diagram, showing that the gun’s bolt structure is clearly inspired by the Lewis light machine gun

M60’s first prototype gun T44

A US Marine The team members used the M60 machine gun in the Battle of Hue in the Vietnam War (one of the bloodiest and longest battles in the Vietnam War)

M13 scatterable ammunition chain

Incomplete disassembly diagram of the M60 machine gun

The M60 used as a hatch machine gun in the 1987 movie "Full Metal Jacket"

The first prototype of the M60 general-purpose machine gun, the T44, was improved and evolved into the T52 type. The T52 type also improved the ammunition supply system of the MG42 general-purpose machine gun and the gas system of the FG42 paratrooper machine gun. The new gun was named T161. Both prototype guns use gas-operated automatic mode, air cooling and ammunition belt feeding, and can only fire fully automatically, while the gas mode uses a unique closed expansion gas device. Compared with other gas structures at the time, the closed expansion gas structure is simpler and very easy to clean.

After many tests and improvements, the T161E3 machine gun was finally developed. In 1957, the U.S. military named the T161E3 machine gun the M60 general-purpose machine gun and officially equipped the troops. This new gun fires 7.62×51 mm NATO ammunition, uses an open-bolt firing method, and has a firing rate of 550 rounds per minute.

The M60 general-purpose machine gun was widely used in the Vietnam War. The Vietnam War was a war that Americans will never forget, and it was also the first war in which helicopters participated in large-scale combat. The U.S. military has deployed more than 10,000 helicopters to participate in the war, and 4,800 were destroyed, of which more than 3,300 were UH-1 "Huey" helicopters. As the door machine gun of the UH-1 "Huey" helicopter, the M60 general-purpose machine gun suffered heavy losses, but the important role played by these helicopters and the M60 general-purpose machine gun cannot be ignored.

Because the M60 makes a pig-like grunting sound when firing on the battlefield, it is nicknamed "The Pig" by soldiers. But there are many theories about the origin of this nickname. Some say it is because the sound when shooting is like a pig, and some say it is because the whole gun weighs 10.9 kg. But one thing is certain, that is, each squad needs to carry 200 rounds of ammunition belts and some spare barrels when using the M60.

The Browning M1917 and M1919 machine guns use M1 ammunition belts for feeding, while the M60 uses a dispersible M13 ammunition belt and fires 7.62mm NATO ammunition. The M60 was originally designed as a squad machine gun. During combat, one soldier was responsible for shooting and another soldier was responsible for feeding. The later version was optimized through structure, and only one person was needed to complete the entire shooting process.

M60 machine gun internal mechanism diagram

A US soldier wearing asbestos gloves replaces the barrel of an M60 machine gun

The excessive weight reduction of the M60E3 machine gun leads to problems such as barrel overheating and greatly reduced reliability

The M60 E4 machine gun equipped by the US "Seabee" engineering corps during the Iraq War in 2003

The M60D machine gun is mainly used as a helicopter door machine gun, which is connected to the combat platform through a pin. Compared with the M60 machine gun, it has two "D"-shaped grips at the rear of the gun, and the sights have also been changed to a ring. To prevent the shell from being rolled into the propeller or sucked into the turbine engine, a canvas shell collection bag is provided at the ejection window. The M60D machine gun is mainly equipped on the UH-1B "Huey" helicopter, and is also equipped on the CH-47 "Chinook" transport helicopter, ACH-47A attack helicopter and UH-60 "Black Hawk" general-purpose helicopter. Now, the M60D machine gun has basically been replaced by a new general-purpose machine gun, but a small number of them are still in service on the SH-60 "Seahawk" ship-borne helicopter.

Although the M60 general-purpose machine gun performed well and played a huge role in the Vietnam War, by the 1980s, this product was slightly backward and insufficient, for example, the transmitter component would malfunction due to excessive vibration amplitude. There are such stories circulating in the market that M60 machine gunners would often lower their heads to look for their lost grips and triggers, and these parts may have fallen into the dense bushes thousands of meters away.

The gas system of the M60 general-purpose machine gun is fixed by only one nut, which is very easy to fall off under the recoil and the heat generated by continuous shooting. Soldiers often tie the gas assembly to the gun, but this makes it more troublesome to replace the barrel.

The lack of a handle is also a design flaw, especially when the barrel needs to be replaced, it will burn the soldier’s hand if you are not careful. To solve this problem, the troops are specially equipped with a burn-proof asbestos glove, but it is not a good idea to change the barrel with gloves on the battlefield.

The receiver of the M60 general-purpose machine gun is designed to be thinner in order to reduce weight. These problems did not appear during the Vietnam War, but in the later period of the gun’s life, especially after firing thousands of rounds of ammunition, the strength problems of the receiver began to emerge, and some receivers even cracked.

To solve these problems, under the auspices of the military, a new M60E3 machine gun was launched and equipped to the troops in 1986. The M60E3 machine gun has done a lot of work in reducing weight, reducing the weight of the entire gun from 10.9 kg to 8.4 kg. In order to achieve the purpose of weight reduction, a thinner barrel is used, and the radio frequency of the gun is also reduced. In order to improve the barrel’s resistance to ablation and wear, a barrel bushing made of tungsten-chromium-cobalt high-temperature alloy is added to the inner bore of the barrel, but the problem of barrel overheating caused by continuous shooting still exists. For this reason, the M60E3 machine gun is equipped with two specifications of barrels according to different equipment conditions. The machine guns equipped by infantry use light barrels, and the machine guns in fixed positions for fire suppression use heavy barrels with better heat dissipation.

In order to improve battlefield adaptability, the M60E3 machine gun is equipped with a bipod mounted on the handguard, which not only improves shooting stability, but also facilitates rapid replacement of the barrel. A small vertical grip is also added below the front of the handguard, which enables the M60E3 machine gun to have the ability to shoot against the shoulder. In addition, the safety device is set on both the left and right sides of the gun body, and a universal sling ring is used, allowing soldiers to carry the gun more flexibly. A handle was added to the barrel, so soldiers no longer had to wear gloves when changing barrels. The gas system was simplified for quick cleaning.

Although the M60E3 machine gun had many targeted improvements, excessive weight reduction directly led to a significant reduction in the reliability of the gun, and even more parts were worn and broken.

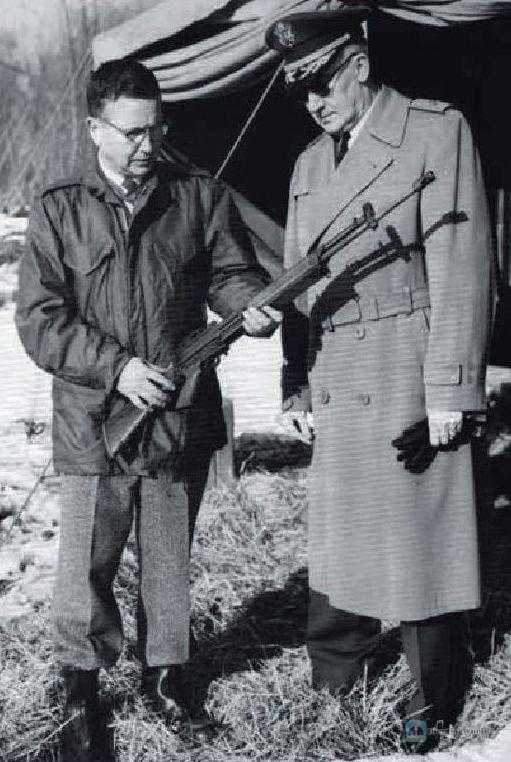

Stoner holding his own Stoner 63 weapon system

The Stoner 63 weapon system family, from top to bottom, is: rifle type, carbine type, automatic rifle type (i.e., light machine gun with magazine feed) and commando type (i.e., short-barreled light machine gun type, with magazine or drum feed)

In order to solve the problems of the M60E3 machine gun in use, the military launched the M60E4 machine gun. Although the appearance of the M60E4 machine gun is very similar to the M60E3, the front grip, mechanical sights, buttstock and bipod used have been slightly improved. In terms of internal structure, in order to improve the reliability of the firearm, the ammunition feeding system has been upgraded, and the bullet ejection mechanism has been improved to increase the ejection force.

The weight of the M60E4 machine gun has increased compared to the previous generation, but it is still only 9.3 kg. Since the standard barrel is equipped with an assault-type short barrel, the M60E4 machine gun is very suitable for street fighting or jungle fighting. The latest M60E4 machine gun has been equipped with a standard M1913 Picatinny rail, which can be installed with optical sights, laser indicators, night vision devices or other tactical accessories. The main parts of the M60E4 machine gun can also be used with all old models and are compatible with all NATO standard mounts. Although the M60 general-purpose machine gun has undergone various upgrades and modifications, its performance has become increasingly perfect, but it was eventually replaced by the M249 squad automatic weapon.

Stoner 63 Machine Gun System (1963)

Eugene Morrison Stoner was born in Gosport, Indiana, USA on November 22, 1922. After graduating from high school, he joined an aircraft manufacturing company and was responsible for the installation of weapons and equipment. After the outbreak of World War II, he enlisted in the army and became an aviation soldier in the US Marine Corps. After the end of World War II, he joined an aviation manufacturing company called Whitaker and eventually became an engineer. In 1954, the 32-year-old Stoner joined Armalite, a subsidiary of Fairchild Aircraft. While working at Armalite, Stoner designed a series of prototype firearms, including AR-3, AR-9, AR-11, and AR-12, but none of them were mass-produced. The only successful one was a life-saving rifle called AR-5, which was adopted by the US Air Force.

In 1955, the U.S. Army was looking for a new rifle to replace the M1 Garand rifle, and Stoner designed an AR-10 rifle that fired 7.62mm NATO ammunition, but it was not recognized by the military. Although the AR-10 rifle, which uses a large amount of lightweight aluminum alloy and high-performance plastic materials, did not win the bid, its excellent performance and advanced design concept during the test process impressed the military. The military suggested that the AR-10 rifle could be appropriately reduced to fire smaller caliber ammunition for further research. So Stoner designed the AR-15 rifle that fired small-caliber ammunition based on the AR-10 rifle, which was later known as the famous M16 rifle.

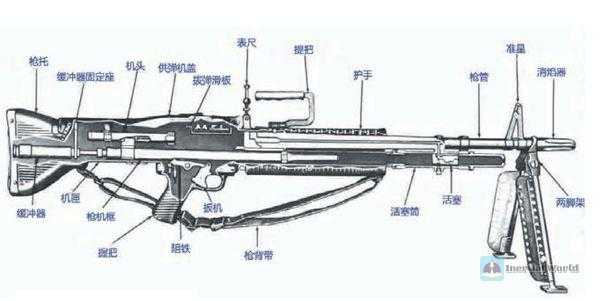

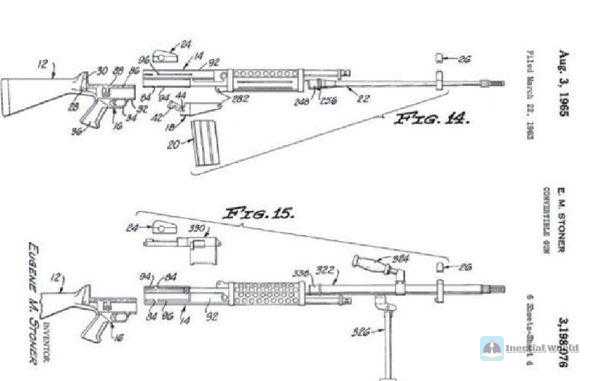

Stoner 63 modular system schematic diagram: the upper picture is a rifle, the lower picture is a machine gun. By comparison, it can be seen that the machine gun receiver is an inverted rifle receiver, the gas system and bolt handle are changed from the upper to the lower arrangement, and the magazine is changed from the lower to the upper arrangement

The lower right corner of the gas piston is three different types of bolt handles. There is a protrusion on the bolt handle that can be hooked on the receiver and does not reciprocate with the movable rod

Close-up of the machine gun bolt, with the piston rod located below the bolt

Rifle type of Stoner 63 modular firearms system, with the gas piston located above the barrel, and the cylindrical protrusion above the handguard is the bolt handle, which is hooked on the piston rod

Barrel components of the Stoner 63 weapon system, from top to bottom: carbine barrel, rifle barrel, automatic rifle barrel (i.e., magazine-fed light machine gun) and light machine gun barrel (gas band with gas regulator)

In 1959, the poorly managed Armalite sold the patents for the AR-10 and AR-15 rifles to Colt. In 1961, Stoner left Armalite and joined another new company to design the Stoner 63 weapon system. In 1972, he founded ARES with his partners and designed the Ares light machine gun, which was improved based on the Stoner 63 and was also called the Stoner 86 light machine gun. In 1990, Stoner joined Knight Arms and designed the Stoner SR-25 rifle (S stands for Stoner, R stands for Rifle, and 25 is the sum of the numbers of AR-10 and AR-15, because SR-25 successfully combines the two), SR-50 semi-automatic sniper rifle and other products.

If the two world wars made John Moses Browning, then the Vietnam War made another gun master-Eugene Stoner. In the early 1960s, Stoner designed a modular firearm that fired 7.62×51mm (.308 Winchester) ammunition. As small-caliber ammunition became popular, this firearm was changed to fire 5.56×45mm NATO ammunition, which is the prototype of Stoner 63. The reason why Stoner 63 is called a modular firearm is that it can be combined into various models of products including rifles, carbines, light machine guns and vehicle-mounted machine guns by changing different parts under the premise of using the same receiver.

The receiver design of Stoner 63 is relatively unique. When it is converted from a rifle to a machine gun, it only needs to be inverted. Therefore, in the rifle form, the gas system and piston are above the barrel, the bolt handle is above the receiver, and the shell is ejected to the right. When used as a machine gun, the gas system and piston are below the barrel, the bolt handle is below the receiver, and the shell is ejected to the left.

The first prototype of the Stoner 63 modular firearm was designed in 1962 and named M69W. Because the English name is the same when read backwards, Stoner thought that this name could reflect the characteristics of this firearm. At the same time, Stoner had a hunch that small-caliber ammunition would soon become popular, so he improved the 7.62 mm caliber of this gun to 5.56 mm. The improved new gun was named Stoner 63 rifle because this gun was officially produced in 1963.

In August 1963, the Stoner 63 rifle was sent to a development center of the US Marine Corps in Quantico for evaluation, and was recognized for its light weight and high ammunition capacity. The testing work was carried out at the Army Materiel Command’s own test site, but the Army was not satisfied with the test results and proposed modifications. Stoner launched the improved Stoner 63A and began production in 1966.

The bolt of Stoner 63 uses 7 locking teeth and barrel sleeve, and the automatic mode is long-stroke piston gas-operated.

The Stoner 63/63A rifle model is the standard model of Stoner 63 modular system, using 30-round magazine for ammunition supply.

The Stoner 63/63A carbine model uses a short barrel and a foldable stock.

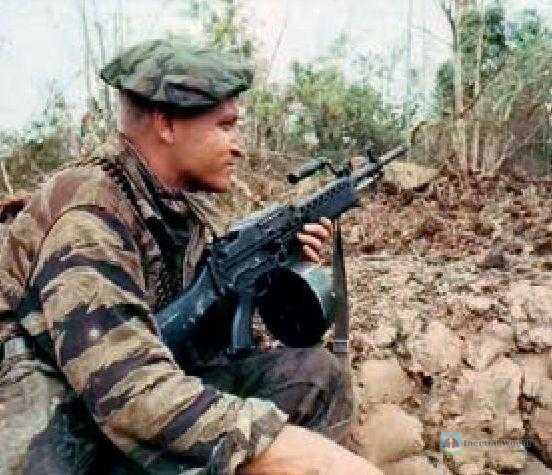

Vietnam in 1970. A Navy SEAL in the middle of the photo is holding a Stoner 63A1 Mk23 Mod0 (i.e. commando) light machine gun

Burst comparison diagram: the upper part is the rifle-type bolt assembly, and the lower part is the machine gun-type bolt assembly (it should be inverted when actually working)

Stoner 63A automatic rifle type exploded diagram

A Navy SEAL is holding a Stoner 63 light machine gun with a 150-round drum magazine. Note that it uses left-side feeding and right-side shell ejection

Stoner 63/63A automatic rifle type is actually a magazine-fed light machine gun. Because the machine gun type receiver is inverted from the rifle type receiver, its 30-round magazine is inserted from the top of the receiver and the shells are ejected to the left. Because the magazine is at the top of the receiver, its front sight and rear sight are designed to be biased to the left.

The Stoner 63/63A light machine gun uses a right-side belt feed, which is placed in the ammunition box under the receiver. The shells are ejected to the left, and the barrel can be quickly replaced.

The Stoner 63/63A Commando is a derivative of the light machine gun, using a drum-shaped or square ammunition box, with the bolt handle located below the handguard, and the handle on the barrel is removed.

The Stoner 63/63A medium machine gun is a light machine gun with a tripod installed. The Stoner 63/63A fixed machine gun is a light machine gun with the butt, grip and mechanical sights removed, and an electric-controlled firing device installed, which can be used on a vehicle or aircraft.

When the Stoner 63 is used as a rifle, it uses a closed-bore firing method to improve the accuracy of the weapon. When used as a machine gun, it uses an open-bolt firing system to improve the heat dissipation capacity of the firearm. The buffer system design of the Stoner 63 is also very unique. The internal conical spring washer absorbs the recoil energy of the bolt by deformation, and the spring washer gives the bolt a certain recoil speed during the reset process. This unique buffer design greatly extends the service life of the weapon.

The early models of the Stoner 63 were distributed to a small team of Navy SEALs fighting in Southeast Asia. The Marine Corps also received a batch of Stoner 63s for testing in 1967, including rifles, carbines, and a few light machine guns. The Army tested the Stoner 63 in 1970, but did not equip it on the grounds that the gun was too complicated and difficult to maintain and repair. The Navy SEALs were quite satisfied with the performance of the Stoner 63 and used it until the late 1980s, when it was finally replaced by the M249 squad automatic weapon.

The reason why the Stoner 63 weapon system is evaluated differently by the Navy SEALs, the Marine Corps, and the Army is mainly due to usage and maintenance issues. As a modular firearm, the Stoner 63 weapon system is relatively complex in structure. If you want to maximize its effectiveness, you must do a very good job of cleaning and maintenance. As special forces, the Navy SEALs have a shorter combat cycle and are more proficient in weapons, which can maximize the advantages of the Stoner 63. When it is used as a conventional weapon and equipped to troops on a large scale, the logistics and maintenance in use are difficult to meet the design requirements of the weapon, so there will be many durability problems.

On April 24, 1997, Stoner died at the age of 74 and was buried in Quantico National Cemetery in Virginia. (To be continued)