Sweden’s "Amos" was once synonymous with high-performance 120mm self-propelled mortar systems, and to this day, it is still the flagship of similar products. But what’s interesting is that although "Amos" is not outdated, Sweden has already launched its replacement product, which is the new generation of "Thor’s Hammer" double 120 self-propelled mortar.

As the replacement product of "Amos", the new generation of "Thor’s Hammer" double 120 self-propelled mortar has entered service in the Swedish Armed Forces in 2019. However, it is interesting to note that the Thor system is very similar to the Amos system. Both are rapid mortar systems, and both use twin mortars as their main weapons. In fact, Thor can be seen as a simplified version of Amos, with a more reliable system and a relatively lower cost. Although Thor received limited attention at the beginning of its service due to its lackluster technology compared to Amos, with the deteriorating security situation in Europe in recent years, Thor, whose performance has declined but the procurement cost has been greatly reduced, should be re-emphasized.

Back Scene

Mortars with a caliber of 120 mm or above are usually called large-caliber mortars. Large-caliber mortars are a lightweight indirect fire support weapon and an indispensable fire suppression weapon for mechanized troops in combat. In particular, howitzers with longer range and greater power are more difficult to use in special battlefield environments such as mountains and cities, so the status of large-caliber mortars is more prominent. However, due to their own weight, ammunition and loading, large-caliber mortars often exceed the upper limit of what human power can bear, so it has long been a consensus among the military of various countries to develop large-caliber mortars into self-propelled and automated ones. . For example, China developed several self-propelled mortars in the 1980s, but all of them were exported. The PLA still used general mortars that were transported by vehicles, which greatly restricted their combat efficiency. At the same time, the Soviet army had begun to equip its airborne troops and marines with various types of self-propelled mortars such as 2S9, 2B16, 2S23 and 2S31. This mortar combines the characteristics of many types of howitzer shells, long range, high degree of automation, fast firing rate, and direct aiming. It is also called a mortar howitzer.

After China introduced the Soviet 120mm mortar howitzer technology in the 1990s, it officially finalized and equipped the Type 05 120mm self-propelled mortar howitzer with the Type 92 wheeled armored personnel carrier as the chassis in 2005, which greatly improved the fire support capabilities of the PLA battalion-level armored troops and regiment-level motorized troops. Since then, the Type 05 120mm self-propelled mortar howitzer has evolved into the Type 10 120mm tracked self-propelled mortar howitzer. The biggest difference between the two is that the Type 10 chassis uses the chassis of the Type 04A tracked infantry fighting vehicle. To this day, the Type 05 and Type 10 120mm self-propelled mortar howitzers It is still the basic indirect fire support equipment for the artillery of various synthetic battalion units of the People’s Liberation Army. Similar to the situation of the Chinese army, the US military also attaches great importance to the 120mm self-propelled mortar. In 2006, the US military took the lead in implementing the transformation of divisions into brigades. Soon after, major military countries were basically promoting similar military organization reorganizations. However, starting in 2021, the US military has returned to the division-level organization on the pretext of so-called great power competition. For example, the reorganized heavy armored division is called the Heavy Breakthrough Division (abbreviated as the Breakthrough Division). The reform of the breakthrough division began with the 1st Armored Division and the 1st Cavalry Division of the US Army. Both units now have three armored brigade-level combat teams under their jurisdiction. In addition, the new breakthrough division of the US military also has an artillery brigade under its jurisdiction. In addition to the brigade headquarters and support battalions, the brigade has a full 4 artillery battalions. One of the four artillery battalions is called the Extended Range Cannon Artillery (ERCA) Battalion, which is equipped with the latest M1299ERCA self-propelled artillery developed by the United States. This self-propelled artillery is developed based on the M109A7 "Paladin" 155mm self-propelled artillery, and is equipped with a 58-caliber XM907E2 artillery, which can launch XM1113 rocket-assisted grenades at a range of 70 kilometers. As for the other three 155mm self-propelled artillery battalions, they are equipped with M109A7, and these artillery were "confiscated" from the three armored brigade combat teams under the breakthrough division. The 18 M109A7 self-propelled artillery in the current field artillery battalion in the US Army’s armored brigade combat team have all been received by the divisional artillery brigade. What is left of the brigade-level armored force? The answer is only the M1287 120mm self-propelled mortar of the AMPV vehicle family series. In fact, although the artillery of the armored brigade combat team under the US breakthrough division is composed entirely of 120mm self-propelled mortars, it is a kind of helplessness, but to a large extent, it shows the importance and irreplaceability of 120mm self-propelled mortars. It is also in this context that, as the country with the highest level of 120mm self-propelled mortar technology in the Western world, Sweden’s new generation of "Thor’s Hammer" dual 120 self-propelled mortars should receive enough attention.

Let’s start with the flagship "Amos"

During World War II, some mortars were temporarily installed on various vehicles to make early simple self-propelled mortars. Although they were successful in tactics, such equipment after World War II was indeed not as good as the development of self-propelled howitzers in terms of production and types, and most of them had low technical content. However, this situation has been greatly improved with the advent of the "Amos" double 120mm self-propelled mortar jointly developed by Sweden and Finland.

In the early 1990s, Sweden and Finland planned to develop a 120mm modern self-propelled mortar for Denmark, Finland, Norway and Sweden. In order to increase the firing rate of the 120mm mortar, they finally decided to adopt a parallel double-barrel setting, which was later the "Amos" 120mm double-barrel self-propelled mortar. In 1995, Sweden and Finland began to jointly design the "Amos" self-propelled mortar system. The overall intention is to create a modular mortar turret that can be easily installed on a suitable mobile chassis. Its core weapon is two 120mm smoothbore mortars set in parallel. Although the two 120mm smoothbore gun barrels are designed in parallel, both barrels have their own recoil devices, which can be fired either single shot or simultaneously. In addition, when the "Amos" was first designed, there were two specifications of chassis configurations. The "Amos" with a tracked chassis design uses a long barrel and can be semi-automatically loaded. The "Amos" with a wheeled chassis uses a short barrel and is manually loaded. As a jointly developed weapon, Sweden and Finland have their own division of labor. Sweden is responsible for the design of the turret part, and Finland is responsible for the development of the 120mm rapid-fire mortar loaded with breech loading.

Generally speaking, the welded armor of the "Amos" turret is not thick and can only withstand attacks from light weapons and shell fragments, but the turret can achieve three-defense capabilities with the chassis structure. The turret can rotate 360 degrees, with electric and manual modes, and has conventional access hatches with periscopes on the top. The main gun is two parallel coaxial breech-loading 120mm heavy mortars. "Amos" can fire conventional high-explosive shells, guided shells and other types of shells. The automatic ammunition handling subsystem in the turret can adjust the ammunition according to the situation. By changing the firing angle and the amount of propellant, a single mortar can achieve the effect of 7 shells hitting the target at the same time, and 2 mortars can achieve 14 shells hitting the target at the same time. The maximum rate of fire of the whole system is 26 rounds per minute (some say 24 rounds). Such firepower coverage capability is comparable to that of a self-propelled howitzer. Some information claims that its destructive capability is roughly equivalent to that of an artillery company. The "Amos" mortar system weighs 4,450 kilograms (turret part), and there are generally 2 people in the turret. The indirect firing range of the main gun is 6 to 10 kilometers, and the direct firing range is 150 to 1,550 meters. The elevation angle of the "Amos" gun is between -3 and 85 degrees. Since it is breech-loaded, "Amos" can also conduct direct-fire shooting. At this time, its maximum range is reduced to 1,500 meters, and it can bombard targets with dense shells. It poses a great threat to soft targets or lightly armored targets, but is powerless against solid targets such as tanks. An automatic electronic target engagement and shooting system is installed in the turret, and it can also be installed on the chassis to cooperate with GPS, digital maps, etc. When "Amos" is fully automatic, after the vehicle receives target coordinates, weather and other information from its superiors, the fire control computer quickly calculates the firing direction, firing angle, charge number and other firing parameters based on the positioning information of the gun, and then sends them to the gun control system through the tactical network. After the fire control system receives the parameters, its gun control system automatically adjusts the gun to complete the aiming, and then the commander issues an order to fire. The entire system reacts very quickly to combat. Due to the calculation, Aiming and ammunition loading operations have been automated. "Amos" has extremely high combat efficiency. It takes only 30 seconds to prepare the gun and 10 seconds to leave the position. When the two guns are fired at the same time (there is a time difference of 0.2 seconds between the two guns), 4 shells can be fired in the first 8 seconds. After firing the shells, the position can be evacuated within 10 seconds to avoid the opponent’s anti-artillery attack. One gun can independently strike or suppress multiple high-value targets. As mentioned earlier, the system has long and short barrels to choose from to cope with chassis with different carrying capacities. The "Amos" system can be installed on vehicles such as the CV90 infantry fighting vehicle chassis, the Pataliya wheeled chassis, and small surface ships. It has a very strong adaptability. Among them, the tracked version of "Amos" can carry 84 120mm mortar shells, including 6 guided shells, because of its large body space to meet the needs of precise strikes on specific targets.

The design concept and technical features of "Thor’s Hammer"

In April 2006, the "Amos" system used the CV90 infantry fighting vehicle chassis of the Swedish company Heglunds to conduct a series of firepower and mobility tests in Saudi Arabia, successfully completing direct or indirect aiming shooting during the day/night, as well as some long-range shooting, demonstrating its strength. The first test target was a small building 700 meters away, and "Amos" hit it by direct aiming shooting. A total of 3 shots were made at this position, all of which hit the target. Subsequently, "Amos" was deployed to a shooting point about 100 meters away from the second test position to shoot at the second building. This shooting only used a single-barrel shooting mode, and the test used the M536A1 120mm grenade, which was equipped with a trigger fuse, and finally all 6 grenades hit the target. In order to test the night combat performance of "Amos", a set of tests was specially conducted at night. The first was a 3-round salvo. The shells used in the test were the M530AI 120mm grenades developed by Mecca. Three double shots were fired at a target 3.2 kilometers away in indirect aiming mode. The multi-shot simultaneous impact technology was verified during the shooting process. Subsequently, a series of tests were organized to demonstrate and verify the time for the system to enter/withdraw from the battle. The first test required "Amos" to move to the designated launch position first, then shoot at the target 2 kilometers away, and then quickly return to the initial position. This process was repeated 5 times, with a total of 10 shells fired. After calculation, it was found that it took an average of 23.1 seconds for "Amos" to enter the launch position and hit the target, and an average of 7.7 seconds to evacuate the launch position after the shooting was completed. The test content then changed to a rapid strike on two different targets, requiring "Amos" to quickly rotate the turret to double-shoot target B after double-shooting target A. This was repeated 4 times, with a total of 16 shells fired. During the test, the average time for Amos to switch targets was 20.6 seconds. In the demonstration of hitting long-distance targets, Amos first fired two shots at the first target at a distance of 5.5 kilometers, and then fired two shots at the second target at a distance of 9.1 kilometers. After five similar demonstrations, the average muzzle velocity was measured to be 442.5 meters per second. In the important demonstration on the last day, Amos fired 20 rounds of shells directly at a container target 700 meters away, and the shells exploded in the container and shattered it.

Of course, the Amos dual 120mm self-propelled mortar system is not without flaws. For example, the maximum range of the gun is about 10 kilometers, which means that it needs to get closer to the target during combat, which increases the risk. However, the bigger problem of Amos is the high procurement cost, and for this reason, the output of the Amos self-propelled mortar system is not high. Even the high procurement cost forced Sweden, the research and development country, to bow its head. After Finland purchased a small batch of production wheeled chassis "Amos" self-propelled mortars, Sweden only purchased two tracked chassis turrets for speedboat experiments...

In fact, the "Amos" is a high-precision but overly expensive 120mm self-propelled mortar system, so in order to reduce procurement costs, its research and development countries Sweden and Finland are seeking more cost-effective alternative solutions. For example, Finland focuses on cost and develops the "Nemo" wheeled self-propelled mortar based on the AMV8x8 modular wheeled armored vehicle chassis produced by Patria. Unlike the "Amos" dual 120 self-propelled mortar system, the "Nemo" mortar uses a single-barrel 120mm rear-loading smoothbore mortar. The advantage of this is that it can save production costs on the one hand, and on the other hand, it can further reduce the volume and weight of the entire turret part. Due to the unmanned turret design, the total weight of the entire turret part is only about 1.5 tons. In addition, the application of modular technology makes it, like the "Amos", very convenient to install on different combat platforms, such as various types of tracked/wheeled armored vehicle platforms, ship platforms and even container platforms. In addition, since the turret of the "Nemo" 120mm self-propelled mortar adopts a certain stealth design, it also has good low detectability. In terms of specific performance indicators, taking the AMV chassis version of the "Nemo" wheeled self-propelled mortar as an example, the vehicle has a crew of 4 people, and the 120mm rear-loading smoothbore mortar equipped on the turret has a 360-degree directional firing range and a high and low firing range of -3~+85 degrees. The vehicle has a reserve of about 50~60 rounds of ammunition and is equipped with an ammunition auxiliary loading system. Its burst rate of fire is 3 rounds/12 seconds, the maximum rate of fire can reach 10 rounds/minute, the continuous rate of fire is 7 rounds/minute, and the maximum range is 10 kilometers. This type of wheeled self-propelled mortar is equipped with a relatively advanced fire control system. In addition to the direct and indirect shooting capabilities, it also has the ability to hit 6 rounds at the same time. In combat, the AMV chassis version of the "Nemo" wheeled self-propelled mortar can fire the first round within 30 seconds after parking, and can quickly withdraw from the current firing position in less than 20 seconds after firing. Therefore, the "Nemo" wheeled self-propelled mortar has a good "quick attack and quick withdrawal" capability. Because of this, this 120mm self-propelled mortar with obvious technical origins with the "Amos" has even attracted the attention of the US Army. Since 2020, the US Army has conducted various tests on the "Nemo" 120mm self-propelled mortar prototype provided by Finland at the Red Cloud Shooting Range in Fort Benning. After all, compared to the AMV chassis version of the "Nemo" wheeled self-propelled mortar, the US Army’s current M1129 120mm wheeled self-propelled mortar with the "Stryker" chassis still uses manual loading, and the maximum range of its ammunition is only about 6.8 kilometers. In addition, it does not have the ability to fire multiple rounds at the same time. Therefore, in terms of overall performance, the M1129 cannot be compared with advanced self-propelled mortars such as the "Nemo". Judging from the current test situation, the AMV chassis version of the "Nemo" wheeled self-propelled mortar has actually demonstrated capabilities including multiple rounds of fire and rapid direct shooting at the Red Cloud Shooting Range in Fort Benning, and its performance is excellent, which can be said to be deeply appreciated by the US Army.

However, the Swedes do not agree with the technical route taken by the Finns on the "Nemo" wheeled self-propelled mortar. Although they are also seeking a more cost-effective 120mm self-propelled mortar solution like the Finns, the Swedes believe that the "Amos" self-propelled mortar system is essentially an ideal solution for pursuing the mortar firing rate. Compared with the single-barrel rapid-fire mortar, the double-barrel mortar is safer and can continue to fight after one gun fails. Moreover, the two barrels can also be loaded with different types of mortar shells, and the battlefield adaptability is stronger. Therefore, although Sweden began to re-conduct the concept of low-cost replacement project for 120mm self-propelled mortars in 2008, it does not intend to abandon the parallel double-barrel concept. The success of this idea The result is the "Thor’s Hammer" 120mm self-propelled mortar, which began to be equipped in small batches by the Swedish armed forces in 2019. According to the Swedish military contract, the "Thor’s Hammer" system is installed on the CV90 infantry fighting vehicle chassis, so people call it CV90 "Thor’s Hammer". Sweden’s official name is GRKPBV90. The total order volume of this self-propelled mortar is currently 40 (which may increase in the future). They will provide indirect support firepower for mechanized battalions.

CV90 "Thor’s Hammer" is a relatively cheap self-propelled mortar system. After adopting a simpler structure and technology The cost of the Thor’s Hammer self-propelled mortar has dropped significantly compared to the Amos self-propelled mortar, and it is said that the purchase cost is only 1/5 of that of the Amos. The Thor’s Hammer adheres to the parallel twin-barrel design of the Amos, but takes a different approach to reducing costs - for example, the CV90 Thor has a steel armored turret with a wedge-shaped front, and its main weapons are two 120mm caliber muzzle-loading mortars, which is significantly different from the breech-loading artillery of the Amos system. In addition, there is an auxiliary loading system above the side-by-side gun barrels of the Thor’s Hammer. The crew manually moves the ammunition to the ammunition feed tray, and the loading system will move the ammunition forward to the muzzle and then automatically align it for loading, thus forming semi-automatic loading. So a CV90 Thor’s Hammer "It still only requires three operators, the driver, the commander and the loader. In fact, people can see four "tubes" distributed in a field shape in the actual photos of "Thor’s Hammer". The two lower ones are mortar tubes, and the two upper ones are the ammunition feed structure. This design allows only a small part of the barrel to be exposed to the outside. Although it does not look so majestic, the actual effect is very good. The "Thor’s Hammer", which also uses a double-tube design, has a rate of fire that is not much lower than that of "Amos". It can fire 4 shells in 8 seconds, with a maximum rate of fire of 16 rounds per minute and a sustained rate of fire of 10 rounds per minute. The "Thor’s Hammer" system can fire all NATO standard 120mm mortar ammunition, including grenade range extenders, infrared smoke bombs, flares, cluster bombs, etc. The maximum range when firing rocket range extenders is 13 kilometers. Moreover, "Thor’s Hammer" can still fire special ammunition such as the Swedish STRIX "Owl" infrared terminal-guided mortar shells without modification.

Here we need to make a special mention of the STRIX "Owl" infrared terminal-guided mortar shell that both "Amos" and "Thor’s Hammer" value very much. The "Owl" is similar in appearance to ordinary mortar shells. It is equipped with an infrared guidance control device on the head, an electronic device in the middle, a solid-fuel rocket engine and fixed wings folded on the body of the shell at the tail. It adopts the top attack mode of enemy armored vehicles with a range of 5 kilometers. The shell has a high hit rate and a armor-piercing thickness of 550 mm. After being launched by the "Amos" or "Thor’s Hammer" system, the four tail wings of the "Owl" are opened, so that the projectile can maintain stable flight. Once the target is found from a high altitude, the infrared guidance device captures the target, and the 12 small rocket engines on the shell body correct the trajectory according to the processor requirements, so that the shell quickly hits the target. Since the shell body is also equipped with a range engine, the "Owl" can attack armored targets 8 kilometers away.

The turret of the Thor’s Hammer is a fully welded structure that can withstand attacks from 12.7mm bullets and shell fragments. In addition, the turret can also be protected by adding passive armor. The turret does not use a traditional periscope, but instead installs a computer-controlled display camera periscope at the commander and gunner’s position. The periscope is combined with six keyhole cameras installed on the outside of the turret through the armor to provide the crew with laser-proof external images. Because the turret adopts a new appearance design that can prevent radar detection, the Thor’s Hammer also has certain low detectability characteristics. Smoke grenade ejectors are equipped on both sides of the turret. However, compared with the Amos, the Thor’s Hammer turret cannot rotate 360 degrees horizontally, the direction angle obtained by the gun is only 60 degrees, and the elevation angle is between 45 and 85 degrees. Although this design reduces combat flexibility to a certain extent, it further simplifies production and reduces manufacturing costs. In addition, due to the simplification of weapons and turret structure, the ammunition capacity of "Thor’s Hammer" has also been increased. The vehicle carries a total of 104 rounds of shells, 56 of which are stored in the ammunition rack behind the turret, and the other 48 are stored in the vehicle body. The rear hatch behind the turret can be opened to expose the ammunition rack for easy replenishment of ammunition. As for the CV90 chassis of "Thor’s Hammer", it is protected by welded steel armor. The basic armor can resist the attack of 14.5mm armor-piercing shells in all directions, and the front of the turret can resist the attack of 30mm armor-piercing shells. The vehicle can be equipped with additional ceramic armor, so that the vehicle has the ability to resist 30mm armor-piercing shells in all directions.

Overall, the CV90 "Thor’s Hammer" 120mm self-propelled mortar continues the basic design style of the "Amos" double-barreled 120mm smoothbore mortar. The modular mortar system has two short-barreled 120mm front-loading mortars installed inside the turret, with a maximum shooting elevation of +85 degrees. The turret is also equipped with the necessary fire control system (but due to cost reasons, the fire control system of the gun does not have the ability to move and fire multiple rounds at the same time). When loading ammunition, it is generally manually placed on the auxiliary loader at the rear of the gun, and then the auxiliary loader loads the shells from the muzzle. Such a semi-automatic loading system has a greatly simplified structure while still maintaining a good rate of fire. In addition, since the turret of the Thor’s Hammer dual 120mm modular mortar system adopts a basket-free design, 56 of the 104 rounds of ammunition it carries are stored in the turret’s tail compartment. Therefore, it not only provides ample space for personnel in the turret, but also makes the storage of ammunition safer, enhancing the survivability of the entire vehicle. In addition, another outstanding advantage of the "Amos" system is that it can be integrated into different platforms to meet the fire support needs of different environments and operations. The same is true for the "Thor’s Hammer" system. In addition to the current tracked and wheeled chassis, namely the Swedish CV90 tracked armored vehicle chassis and the Finnish XA-203 wheeled armored vehicle chassis, the "Thor’s Hammer" turret can also be installed on the extended M113 armored vehicle, LAV-III and other chassis. When equipped with different chassis, the combat weight of the "Thor’s Hammer" is also different. In addition to the mobile platform on land, the "Thor’s Hammer" can also be used to equip watercraft with a displacement of more than 19 tons.

Procurement and deployment

In 2007, the Swedish Ministry of Defense planned to purchase at least 12 production-type "Amos" systems, but due to the high procurement costs and the relatively relaxed defense environment at the time, this plan was ultimately not implemented. However, with the tremendous changes in the European defense environment since 2014 and the successful development of the CV90 "Thor’s Hammer", Sweden, which is seeking to join NATO, will use this simplified version of the dual 120 self-propelled mortar to realize its previous defense plan. In fact, in 2018, the Swedish Ministry of Defense has purchased 12 "Thor’s Hammer", and the first batch of artillery has entered the combat sequence of the Swedish Armed Forces in 2019. In addition, Sweden also plans to integrate the "Thor’s Hammer" system into the tracked and wheeled chassis of the SEP modular armored tactical vehicle family to meet the long-term needs of the Swedish Armed Forces, especially for the formation of the "European Battle Group"

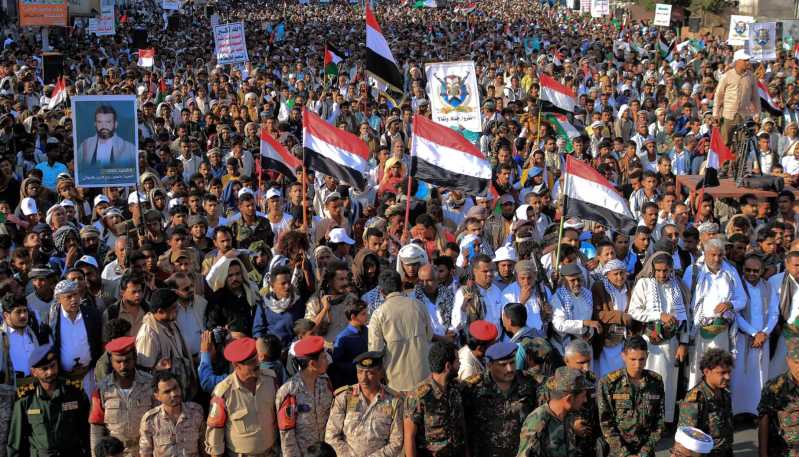

In 2003, EU countries began to build the so-called "European Battle Group". Poland, Ukraine and Lithuania have successively formed a trilateral joint force, and Sweden, Finland and Germany have signed a military agreement to jointly form a joint force. This is a small-scale joint force usually formed by several countries in the European Union, with each force of about 1,500 people. The EU plans to establish a total of 18 such forces as the backbone of the EU’s rapid response force. Because this force is small in size and flexible in composition, it helps the integration of the armies of European countries and is therefore regarded as the prototype of European joint defense. After the outbreak of the Crimea incident in 2014, the security situation in Europe began to deteriorate, and the formation of the "European Battle Group" began to enter the fast lane, especially in the two areas of defense funding and defense institutions. In the field of defense funding, in June 2017, European Commission Vice President Jyrki Katainen announced in Brussels that the EU will formally establish a European Defense Fund with a total amount of 5.5 billion euros. The fund will be used to coordinate, supplement and expand the defense research and development investment of member states, as well as the procurement of defense equipment and technology. He said, "The European Defense Fund will become a catalyst for the revitalization of the European defense industry, and each member state will develop more and more advanced defense equipment. These technologies and equipment can be connected to each other to strengthen our defense integration." In the field of defense institutions, the EU has established a series of military command organizations since 2017, which has continuously strengthened the degree of military integration in Europe. On April 11, 2017, the EU established the EU Cyber Information Warfare Center in Helsinki, Finland. It is composed of 10 personnel from France, Germany, Poland, Sweden, Finland, Lithuania and other countries that signed the contract. The annual budget is 1.5 million euros. It is mainly responsible for studying how to deal with cyber attacks and false propaganda. In June 2017, the European Commission approved the establishment of the Military Planning and Execution Capability Headquarters. It is affiliated to the EU Military Staff, with a staff of 25 staff members, and is under the leadership of the Director of the EU Military Staff. On the same day, the European Tactical Airlift Center was established in Zaragoza, Spain, which will strengthen the training cooperation of EU member states in air transport and enhance the air transport capabilities of member states. More importantly, on November 13, 2017, the European Union formally approved the establishment of a "Permanent Structured Cooperation" mechanism in the defense field, which was signed by 25 member states and decided to work together to develop defense capabilities, invest in defense projects and deploy military operations. This is a key step in European defense integration in nearly half a century.

On June 25, 2018, the defense ministers of 10 European countries, including France, Germany, Belgium, the United Kingdom, Denmark, the Netherlands, Estonia, Spain, Sweden, and Portugal, signed a letter of intent for the "European Intervention Initiative" in Belgium, promising to establish a joint military intervention force to respond to possible crises in Europe and to be able to quickly dispatch troops and intervene in time when conflicts break out. Therefore, taking the opportunity of forming the "European Battle Group", not only will the Swedish army purchase more "Thor’s Hammer" dual 120 self-propelled mortars, but other European countries may also extend an olive branch to "Thor’s Hammer". For example, the Czech military has been conducting feasibility studies on purchasing "Amos" or other alternative systems since 2020. On April 14, 2021, the Czech Republic announced a tender for the purchase of 234 new wheeled armored personnel carriers (199 of which were confirmed and 35 were intended for purchase) to replace the current OT-64 transport vehicles. Since Patria participated in the tender held by the Czech side and is likely to win, some of the armored personnel carriers provided by the company may be equipped with the "Amos", "Nemo" or "Thor’s Hammer" system. Since the "Thor’s Hammer" system has the highest cost-effectiveness among the three options, the Czech military is very likely to become the second buyer of the system. In addition, Turkey is also a potential buyer of the "Thor’s Hammer" system. Sweden suspended arms exports to Turkey in October 2019 due to Turkey’s military operations against the Syrian Kurdish armed "People’s Protection Units". However, since Sweden was opposed by the seven Turks when it applied to join NATO in May 2022, after several rounds of negotiations, Turkey, Sweden and Finland signed a memorandum at the end of June 2022, confirming that Turkey agreed to Sweden and Finland joining NATO, Sweden and Finland would not support the Kurdistan Workers’ Party, the "People’s Protection Units" and the "Gulen Movement", and agreed to lift restrictions on the export of defense equipment to Turkey. In the list of Swedish military equipment that Turkey is interested in, the double 120 mortar system has always been listed.

Conclusion

After the Napoleonic Wars more than 200 years ago, Sweden adopted a politically neutral position, which lasted for more than 200 years. At present, the Swedish army has only 14,600 active full-time soldiers and 10,000 reservists. However, despite its small size, it is well-equipped. Sweden not only has 531 main battle tanks and infantry fighting vehicles, 96 fighter jets and 5 submarines, but also an independent defense industry. Interestingly, although Swedish defense industry products are generally known for their high quality, precision and cutting-edge, equipment such as the "Thor’s Hammer" dual 120 self-propelled mortar reflects the pragmatic side of the Swedish defense industry.