After World War II, the Netherlands, relying on its developed shipbuilding industry, has always insisted on independently designing and building submarines, and has successively developed a variety of conventional submarines with excellent performance. However, the Dutch Navy has limited demand for submarines, and has been slow to successfully enter the international market like European countries such as Germany, France, and Sweden, and cannot support the long-term and stable development of its submarine industry; and due to the poor management and bankruptcy reorganization of related shipyards, its submarine development capabilities have been seriously damaged, and it is currently unable to independently complete the development of a new generation of submarines. The service life of the Walrus-class conventional submarines currently in service in the Dutch Navy will end around 2025. The Dutch Ministry of Defense plans to have foreign companies and local companies jointly design and build a new generation of submarines for the Navy, with a project budget of approximately 2.5 billion euros. The new generation of submarines will maximize the use of technology from local Dutch companies and be built domestically. It is expected that the first submarine will be put into service around 2027. On November 16, 2022, the Dutch Ministry of Defense requested quotations for four new submarines from the French Naval Group, the Swedish Subaru Company, and the German ThyssenKrupp Marine Systems. It is expected that the three companies will submit their respective bids in 2023.

Development of submarine forces

Although the Netherlands is a small country, it has advanced technology and strong industrial strength. It has produced 12 Fortune 500 companies such as Shell Oil, Philips, Unilever, and Akzo Nobel, as well as important companies such as ASML and NXP that determine the global semiconductor industry landscape. The Netherlands is also a country with a long history of maritime trade, and its navy was once one of the most powerful navies in the world. The Dutch Navy believes that submarines are very suitable for protecting ships and offshore platform facilities on sea routes, destroying invading enemy ships, supporting special operations and intelligence collection, and has always attached great importance to the construction of submarine forces.

As early as 1907, the Dutch Navy introduced a license from the United States to produce the "Holland-type submarine" and established the first submarine force. By the 1930s, the Netherlands had the ability to independently design and build large ocean-going submarines. During World War II, Nazi Germany invaded the Netherlands, and the Dutch submarine force joined the Allied side to fight and achieved impressive results. After the war, the Netherlands joined NATO, and the submarine force continued to receive technical nourishment from Britain, Germany, and the United States. In the 1950s, the Netherlands began to gradually resume the design and construction of submarines. Its submarine industry is good at inheritance and dares to innovate. In addition, as it is in NATO, it can choose submarine equipment with advanced performance and mature technology from NATO countries, and learn from the strengths of Western submarine technology. For a time, it has achieved a distinctive and excellent performance of the Dutch submarine development route. From the end of World War II to the 1990s, the Netherlands designed four types of conventional torpedo attack submarines, namely the Dolphin-class, Sailfish-class, Walrus-class, and Eel-class, and built and equipped a total of 10 Dolphin-class (4 ships), Sailfish-class (2 ships), and Walrus-class (4 ships). submarines. Due to the need to participate in military operations within the NATO framework and protect overseas interests, the Dutch Navy requires its submarines to have the ability to be deployed in the ocean.

The "three-body" submarine that dares to innovate-Dolphin class

The 1950s was a period of great development in world submarine technology. In 1954, based on the experience of using submarines and the unique understanding of submarine technology, the Netherlands successfully developed the amazing "three-body" conventional submarine-Dolphin class. This is also the first submarine designed and built by the Netherlands after World War II. There are 4 submarines of this class, which adopt a multi-pressure hull that is extremely rare in submarine design (the Soviet Typhoon-class ballistic missile nuclear submarine uses a similar structure), a double hull structure, and 3 pressure hulls of the same diameter: the finished product is arranged in a Chinese shape, and the upper pressure hull is arranged with a torpedo compartment, a command compartment and a crew compartment; the lower two pressure hulls are arranged with battery packs, diesel generators and propulsion motors and other equipment. The Dolphin class is 79.5 meters long and 7.8 meters wide: the underwater displacement is 1,826 tons, and the maximum underwater speed is 17 The Dolphin class has a small pressure hull diameter, high structural strength, and large space between the sides, which makes its reserve buoyancy and maximum diving depth (300 meters) significantly better than conventional submarines built by various countries at the same time. However, the complex "body" structure inevitably brings disadvantages such as difficulty in construction and maintenance. Although the Dolphin class has an alternative structure, it has good overall performance and a successful overall design, which fully reflects the technical strength of the Dutch submarine industry.

The Sailfish class striving to be the first

After the mid-1950s, the United States adopted the technology verified by the epoch-making "Albacore" conventional submarine to design and build the teardrop-shaped Long-jawed Barbel class conventional submarine and the Skipjack class attack nuclear submarine. In order to replace the Dolphin class, the Netherlands began to develop the second generation of post-war conventional submarines, the Sailfish class, in 1965, using the Long-jawed Barbel class as the mother model. This class of boats adopts a teardrop-shaped hull, double-hull structure, large compartments, single-axis, single-propeller, electric propulsion, and a cross-shaped tail rudder; the underwater displacement exceeds 2,600 tons, the maximum underwater speed is 20 knots, and the endurance is 10,000 nautical miles/9 knots in the snorkel state; the crew has good living conditions, the hull is made of American HY-80 high-strength steel, and the maximum diving depth is more than 220 meters; 6 533 mm torpedo tubes are installed on the bow, which can carry 20 American NT 37D or Mk 48 torpedoes; the submarine fire control system is the Mk-8 torpedo firing control system of the Dutch Signal Company; the sonar system is the DSQS-21 medium-frequency active/passive sonar and medium-frequency passive ranging sonar of the German Krupp Company; the search and attack periscopes are from the British Barr and Stroud Company (Barr &Stroud)

The Sailfish class is a large ocean-going conventional submarine with excellent performance. Its main performance indicators have reached or are close to the level of the third-generation conventional submarines after the war. Two were built and put into service in August and October 1972, respectively, and retired in 1994 and 1995. The Sailfish class has a long history with my country. In the early 1980s, in order to save the Scheldt Naval Shipyard (RSV) which was in financial crisis, the Dutch government exported two improved Sailfish-class submarines to Taiwan, my country. Not only did it fail to save the company’s fate, but it also caused the Netherlands to fall into a serious diplomatic dispute.

The domineering Walrus class

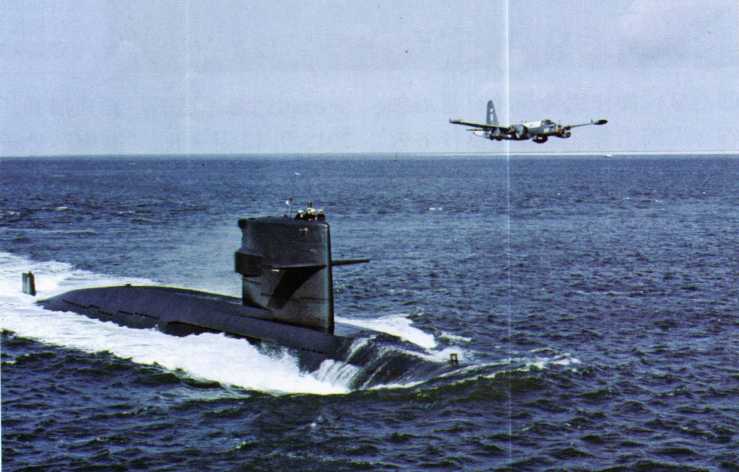

In the late 1970s, the world’s submarine technology developed rapidly, and countries began to develop the third generation of post-war conventional submarines. Although the main performance indicators of the Sailfish class can reach or approach the standards of the third generation of submarines, due to its early development time, some new technologies have not been adopted in time. The Dutch Navy decided not to continue to build the Sailfish class, but to design a new submarine based on it. The new boat is named Walrus class, with an underwater displacement of 2,845 tons, a maximum underwater speed of 20 knots, and a cruising range of more than 10,000 nautical miles/9 knots in the snorkel state; it is built with French high-strength steel and has a maximum diving depth of more than 300 meters; the Walrus class adopts an X-shaped tail rudder after the Swedish Sjoormen class, and the line shape has been optimized on the basis of the Sailfish class; the sonar system is the TSM-2272 medium-frequency active/passive sonar and DUUX5 low-frequency passive ranging sonar of Thomson Sintra of France, and the 2026 low-frequency towed array sonar of GEC Avionics Company of the United Kingdom; the combat command system is the SEWACO-VIII combat data automatic processing system produced by the Netherlands Telecom, equipped with a "Gypsy" data system and an integrated fire control system; there are 4 533 mm torpedo tubes at the bow of the boat, which can carry 20 Mk 48 Torpedo or "Harpoon submarine-launched anti-ship missile.

The Walrus class is a large ocean-going conventional submarine with advanced command and control, detection system, and weapon system performance. The whole boat has a high degree of automation, good quietness, good crew living conditions, and strong anti-ship and anti-submarine combat capabilities. It is one of the most advanced conventional submarines in the world in the 1990s. Its reliability is particularly worth mentioning. Every year, the Dutch Navy has three Walrus class submarines that maintain about 150 days of sea training time.

From 1990 to 1994, four Walrus class submarines were built and put into service. After more than 20 years of use, the mission situation has also changed greatly, and mid-term overhaul and modification upgrades are urgently needed. The Life Extension Program (LEP) of the Walrus class officially began in May 2013, mainly by enhancing its near-shore shallow water combat capabilities and integrating new weapon systems to extend its service life to Around 2025. The Defense Equipment Organization (DMO) under the Netherlands Ministry of Defense awarded ImtechMarine the main contract for the life extension of the Walrus class. The project was completed by ImtechMarine and the Netherlands United Shipbuilding Bureau (Nevesbu), involving the navy, industrial departments and scientific research institutions. It is a complex team project with a cost of more than 100 million euros. As the integrator of the platform system of the project, Nevesbu carried out the modification of new systems and boat-borne equipment, with 110 to 150 personnel working at the construction site every day.

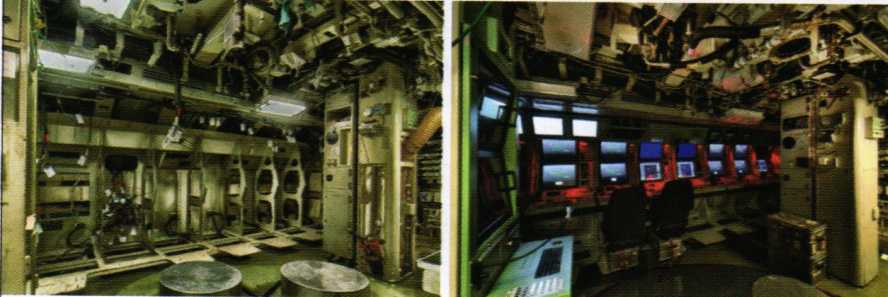

The main overhaul and upgrade contents are as follows: 1. Replace the "Sevaco _Ⅷ" combat data automatic processing system and the "Gipsy" (GIPSY) data system with a new combat management system (CMS); 2. Replace the optical periscope with a non-penetrating optoelectronic mast produced by the US L-3 KEO (formerly Kollmorgen Optoelectronics); 3. Replace the radio communication mast with an ultra-high frequency satellite communication mast; 4. Replace the Mk48 torpedo from The mod4 type was upgraded to the mod7 type; 5. A new mine and obstacle avoidance sonar (MOAS) produced by the German ELACNautik company was installed at the bow; 6. A new passive sonar processing system (PSPS) was installed; 7. The diesel engine, electric motor, shaft system, propeller and other power systems and propulsion equipment were overhauled and maintained; 8. The original coating on the outside of the pressure hull was removed, the pressure hull was repaired, and 4 layers of new coating were applied; 9. Various cables and pipelines were re-laid; 10. The combat command center was renovated and renovated, and a new multi-task console was reinstalled for the combat management system, sonar, optoelectronic mast, weapon control system and other equipment. It is located on the starboard side of the combat command center, which is more simplified in operation and more in line with human factors engineering. It can improve mission efficiency while reducing the fatigue of crew members working for a long time; 11. The traditional paper chart navigation was replaced by an information-based navigation control system; 12. A new central air monitoring system was installed to ensure real-time monitoring of the air quality in the boat; 13. All electronic equipment on the boat was replaced by digital equipment from analog equipment.

The first ship to receive the life extension modification was the No. 2 "Sea Lion", which was commissioned in April 1990 and has the longest service life. On May 13, 2013, the modification project was officially launched at the Den Helder Naval Shipyard in the northwest of the Netherlands. On December 3, 2015, the "Sea Lion" was re-launched and returned to service after a series of tests. According to the plan, the three boats "Dolphin", "Bruinves" and "Walrus" will complete the life extension project in turn.

The Sea Eel Class

In the early 1990s, the Dutch Rotterdam Dry Dock Company (RDM) completed the preliminary design of the Dutch fourth-generation conventional submarine Sea Eel Class. The Sea Eel Class adopts a single-hull structure, a long teardrop line, a cross-shaped tail rudder, and uses the SPEC-TRE closed-cycle diesel engine AIP auxiliary power system jointly developed by the German TNSW company and the Rotterdam Dry Dock Company. Compared with the AIP systems such as the "Stirling" engine and fuel cell, it has the advantages of simple operation, low cost, and high underwater endurance, but its working noise is the largest among the existing AIP systems. The maximum underwater speed of the Sea Eel Class is 20 knots, the maximum range is more than 10,000 nautical miles; the self-sustaining capacity is 65 days, and the maximum diving depth is 360 meters; there are 6 533 mm torpedo tubes at the bow, and the standard model can carry up to 20 torpedoes.

The Moray class is designed based on the needs of the Netherlands and the needs of selling to the international market. It is designed and built with modular technology. Users can choose between 1,100 tons, 1,400 tons and 1,800 tons of displacement according to mission requirements. The onboard hydroacoustic, electronic equipment and weapon systems can also choose products from different countries according to customer requirements.

With the disintegration of the Soviet Union, the international security situation has changed greatly. Western countries have postponed the purchase of a new generation of submarines. The Moray class has neither received orders from the Dutch Navy nor been successfully exported to the international market. Although Taiwan has always hoped to continue to introduce Dutch submarines, with the precedent of the Sailfish class, the Netherlands dare not offend China, whose comprehensive national strength has become increasingly strong, for a few submarines. In the 1990s, the Rotterdam Dry Dock Company has been trying to promote the Moray class to Indonesia, Thailand, Egypt and other countries, but they were all defeated by the German Type 209 submarine. Until the 2000s, when the German Type 212A and the French Scorpio class matured, the Moray class remained on the drawing board.

A new generation of conventional submarines

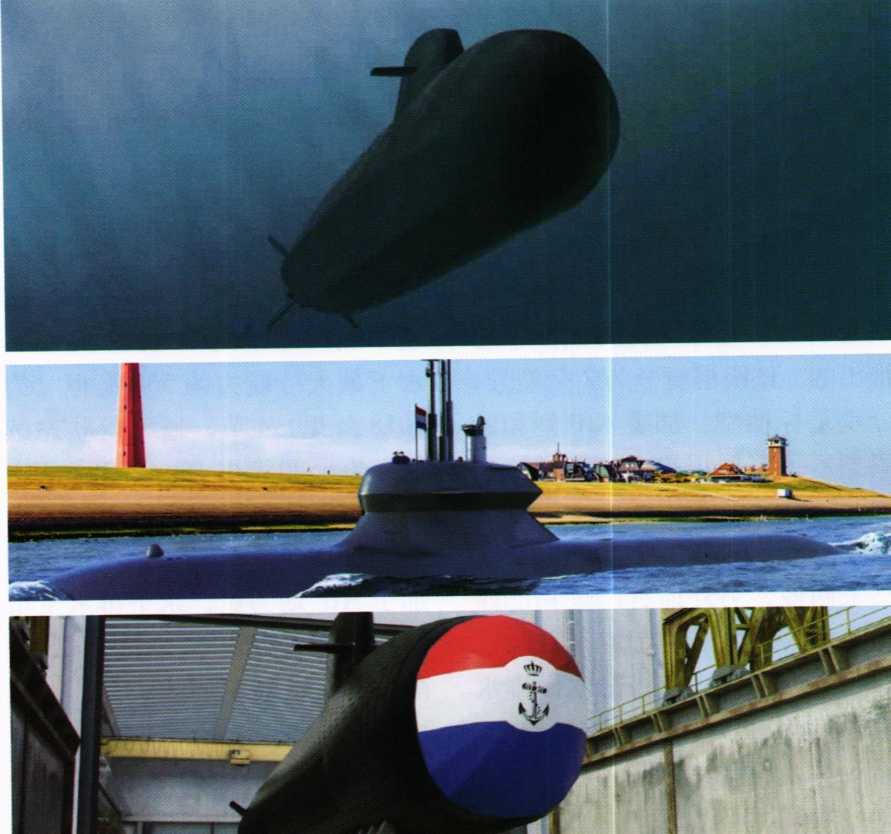

After years of stagnation in the development of the Dutch submarine industry, it has been unable to independently complete the development of a new generation of submarines. The Netherlands plans to purchase four new submarines, the Walrus Replacement Program (WRES), to replace the Walrus class that will be retired after 2025. The new submarines are required to adopt the latest technology, the underwater displacement must be controlled below 3,000 tons, equipped with an AIP auxiliary power system, take into account both near-shore and offshore combat capabilities, provide reliable support for special forces, and have strong intelligence gathering capabilities.

The new submarine will be put on international bidding. Foreign companies must jointly bid with Dutch companies to design and build a new generation of submarines, and the new submarines must be assembled and built in the Netherlands, which will create considerable employment opportunities for related industries in the Netherlands. The Netherlands hopes that its naval equipment construction companies and scientific research institutions will actively participate in the design, construction and later maintenance of new submarines, increase the necessary knowledge and skills, and enter the product supply chain of foreign submarine construction companies.

Initially, the French Naval Group, Spanish Navantia, Swedish Saab-Kockums, and German ThyssenKrupp Marine Systems participated in the bidding for the new submarine. On December 13, 2019, the Dutch Ministry of Defense released the shortlist for Phase B of the Walrus-class submarine replacement program, confirming that Navantia was not selected and the remaining three contractors were shortlisted. In November 2022, the Dutch Ministry of Defense asked the three companies to submit quotations, and it is expected to bid in 2023 and sign a contract around 2024.

Proposal of Swedish Saab Group and Dutch Damen Shipbuilding Group

The two groups signed an agreement to jointly bid for the Walrus-class replacement project and jointly build a new generation of submarines for the Netherlands. On March 1, 2020, the two sides simultaneously announced the concept map and main performance parameters of the Walrus-class replacement boat. The plan is based on the A26 submarine built by Saab Group for the Swedish Navy, and draws lessons from the Collins-class exported to Australia by Swedish Kockums. The new boat has an underwater displacement of about 2,900 tons, a crew of about 35 people, and is equipped with 6 533 mm torpedo tubes and 1 1,500 mm large-caliber multi-purpose launcher; the AIP auxiliary power system is a "Stirling" engine, which adopts a modular design, is easy to upgrade and transform, and allows the integration of Dutch company products. The new boat retains the large-caliber multi-purpose launcher located at the bow of the A26, which can be used as a channel for special forces to enter and exit the submarine underwater, or for launching and recovering unmanned underwater vehicles (UUVs) and other payloads. Although the Swedish submarine company had "fallen over" in the Collins-class project, "every failure makes one wiser", and the A26 submarine has fully considered the needs of ocean operations.

After the acquisition of Kockums by Saab Group, it has strong international competitiveness in the design and construction of submarines and surface ships, modern materials and manufacturing, and system integration. The Dutch Damen Shipyard Group builds more than 160 ships every year and is a strong and dynamic shipbuilding company. The group’s "Sigma" series of new concept frigates have achieved good sales performance in the international market in recent years, and have been purchased by the navies of Indonesia, Morocco, Mexico and other countries. The author is more optimistic about the final victory of the Saab-Damen design plan. The two companies are most likely to cooperate on an equal and mutually beneficial basis. If the new generation of Dutch submarines eventually falls to "Saab-Damen", the two companies may also jointly bid for submarine projects in other countries in the future. Moreover, it is not impossible for the Netherlands to restore its submarine design and construction capabilities by jointly designing a new generation of submarines.

The French Naval Group and the Royal Dutch IHC Company’s plan

The two companies formed a partnership and used the French Naval Group’s design based on the Shortfin Barracuda class (which once won the contract for Australia’s new generation conventional submarine project, but was later unilaterally cancelled by Australia) to participate in the Netherlands’ new generation submarine bidding. The performance of the Shortfin Barracuda class is very consistent with the needs of the Dutch Navy and will be a strong competitor to Saab-Damen’s A26-based design.

The French Naval Group allows users to assemble and build submarines on their own in the submarine projects exported to Brazil, India and Australia, and attaches importance to the transfer of intellectual property rights. IHC is a company specializing in the integration of complex marine engineering systems and is well-known for designing and building dredgers. The French Naval Group has established a solid partnership with it. Although most of the design work will initially be completed in Cherbourg, France, this capability will be transferred to the Netherlands, and the French Naval Group and HC have reached an agreement that IHC will send technicians to France to learn relevant skills starting in 2020. Ultimately, IHC will be responsible for building the modules and assembly of the submarine, and the Netherlands will fully carry out independent maintenance throughout the life of the submarine.

German ThyssenKrupp Marine Systems (TKMS) and the Dutch Den Helder Naval Maintenance Base Plan

They will jointly bid for the new generation of Dutch submarines based on the design of the 212CD type (whose underwater displacement is about 2,400 tons, much larger than the 212A type, and closer to the 2,800-ton Walrus class) selected by Norway and Germany. TKMS, with its brilliant submarine sales performance, is definitely a heavyweight competitor. In terms of designing and building conventional submarines that meet the needs of the Netherlands, TKMS is confident that it has advantages in procurement costs and life cycle costs, risk control, and domestic and foreign division of labor and cooperation, and allows the submarine’s combat command system to integrate software designed by Dutch companies; TKMS also has mature fuel cell AIP technology. If it wins the bid, it will build submarines in Den Helder, the Netherlands, and related companies involved in Dutch submarine construction will enter the German submarine construction industry chain.

Conclusion

No matter who will win the contract for the development of the new generation of submarines in the Netherlands, it is regrettable that the Dutch submarine industry, which once "founded a school of thought", has come to the point where it needs the help of foreign companies to complete the development of submarines. The reasons are worth exploring.

First, although the Netherlands attaches importance to the construction of submarine forces and the development of submarine technology, it does not regard the submarine industry as a strategic industry and provide long-term policy support and protection to ensure its stable and continuous development. There is a lack of reasonable arrangements for the development and procurement of new generation submarines, resulting in the serious damage to the development capabilities of Dutch submarines with the downturn in the shipbuilding industry and poor business operations.

Second, the Netherlands lacks an organization similar to the German "Submarine Sales Alliance" to integrate domestic submarine design, construction and equipment supporting forces and provide financial support for its development of international markets.

Third, the Dutch self-use submarines are far less adaptable to user needs than the German export submarines. Most purchasing countries need "economical and practical" offshore small and medium-sized submarines, rather than ocean-going large submarines. Most Dutch submarines pursue high performance and ocean-going combat capabilities: underwater displacement of more than 2,600 tons, maximum diving depth of more than 300 meters, which can be described as large "luxury version" submarines (the situation of Japanese submarines is similar), which exceeds the needs of the navy of ordinary countries.

Fourth, submarine sales should also be "cautious and fight the first battle well", and take advantage of the favorable situation created by the first victory to open up the situation. In the process of opening up overseas markets, the Dutch submarine industry failed to grasp the first sale (Taiwan is not a normal military sales target), and the export situation did not open up; originally, the Dutch submarines had a great advantage in the Canadian Navy’s Oberon-class submarine replacement project, but eventually lost to the British "free" sales strategy (Canada paid a symbolic pound of 1 and got 4 British Supporter-class submarines that had been in service for less than 10 years, but the modification and upgrading must be the responsibility of the UK).

Fifth, the Dutch submarine industry chain is not as complete as that of Germany and France, which has an adverse impact on its submarine exports. The Dutch submarines lack basic supporting capabilities such as high-strength steel, high-performance integrated sonar systems, heavy wire-guided torpedoes, and anti-ship missiles, and are heavily dependent on other countries (such as American torpedoes, German and French sonars, etc.). The improved Sailfish class purchased by Taiwan once had an embarrassing situation where there were no torpedoes available.

Sixth, selling submarines, an offensive weapon of great strategic value, to politically sensitive regions, the political risks far outweigh the economic benefits. The Netherlands’ sale of submarines to Taiwan has caused it to suffer huge political and economic risks, which is very embarrassing, and ultimately failed to save its submarine construction company on the verge of bankruptcy.