Recently, the MGS 155mm 8X8 truck gun developed by the Indian Defense Research and Development Organization (DRDO) showed the shooting screen, which gave us a certain understanding of this rather mysterious 8X8 truck gun. Its semi-automatic loading system and the entire vehicle design are quite innovative. Previously, we knew that the Indian artillery force has always been mainly equipped with towed artillery, and basically no self-propelled artillery. Now the emergence of the MGS truck gun is expected to bring key and revolutionary technological changes to the Indian artillery.

Difficult development process

For decades, India has been trying to make a fuss about 155mm large-caliber howitzers. Since self-development faces insurmountable technical barriers, foreign procurement faces frequent procurement scandals, and the military/bureaucratic agencies are slow and bureaucratic, so it can be said that it is "extremely difficult". On November 23, 2014, the Indian Defense Acquisition Committee and the new Defense Minister Manohar Parrikar approved the Indian Army Field Artillery Rationalization Plan Proposal to purchase 814 155mm artillery at a cost of 157 billion Indian rupees (about 2.56 billion US dollars), and issued a new tender, which contains the "Buy and Make in India" clause, allowing cooperation with foreign countries, but forcing the entire artillery weapon system to be manufactured in India. This includes 180 self-propelled wheeled artillery at a cost of US$900 million to US$1 billion. Therefore, faced with the stringent requirements of technology introduction, major Indian manufacturers had to develop a 155mm howitzer of "Indian origin" based on the domestic 155mm artillery system combined with the domestic chassis. For example, the "Dhanush" truck gun developed by the "Dhanush" howitzer with an 8x8 chassis. At the beginning, the design and development unit concentrated all the parts at the rear of the vehicle, and the design was very complicated. Later, India’s Tata Company and South Africa’s Daniel Company, which has the ability to develop large-caliber howitzers, developed the so-called TATA-155 truck gun, which directly added a new highlight to the classic G5 gun of Daniel Company. In terms of technology, it lacks both novelty and new technology, and feels a bit perfunctory.

MGS 155mm 8x8 truck gun

In contrast, the MGS 155mm 8x8 truck gun developed by the previously notorious Indian Defense and Development Research Organization DRDO, Tata Group and Kariniya Group is quite good-looking and has a certain level of technology. First of all, it uses a newly designed truck chassis, which is the 8x8 HMV (High Mobility Vehicle) 15009 military truck chassis developed and produced by Ashok Leyland, India. This chassis is likely to be modified on the basis of SUPER STALLION 8x8, with a new armored cockpit designed by the Vehicle Development and Research Institute (VRDE) and a 325 kW/441 hp T3D-928-70 8-cylinder air-cooled 4-stroke direct injection turbocharged diesel engine that meets the BharatStagel V (Euro-IV) standard. The combat weight is about 30 tons, the payload is 17 tons, the power-to-weight ratio is 10.15 kW/ton, the climbing ability is 20°, the wading depth is 1.2 meters, the turning radius is 25 meters, the maximum speed is 80 km/h, the off-road speed is 40 km/h, it is equipped with a central tire inflation/deflation system, and a new hoe system is installed at the rear of the chassis. It can go off-road at an altitude of up to 4,800 meters and adapt to temperatures of -4 to +45 degrees.

MGS155mm 8X8 truck gun uses a special stepped armored cockpit to provide bulletproof and explosion-proof protection for the crew. It has a special appearance, with a low front cockpit and a high rear crew compartment. Its members include the driver and the commander, gunner and first loader sitting in the front cabin, as well as the second loader in the rear middle cabin. The vehicle integrates advanced systems such as the automatic alignment and positioning system for the gun, the integrated fire control system (FCS), the ammunition management system, the on-board silent power system, and the shovel-type shock-absorbing electromechanical system. It also includes communication systems, direct aiming equipment, barrel temperature sensors, propellant temperature sensors, recoil sensors, muzzle velocity radars, etc., which can automatically adjust the gun in the gunner terminal of the carriage. In order to fix the vehicle body when firing, its spade adopts an outward swing extension design with an outward eight-character shape, and the rear vehicle body is raised before shooting. But this will cause the tail of the gun to be too high, so the Indians have also found a way to remedy it.

The vehicle is equipped with a huge 155mm/52-caliber artillery system developed by DRDO-TATA/Kalyani at the rear of the chassis. This is actually the barrel of the ATAGS self-propelled howitzer once developed by India. Speaking of the development of the ATAGS self-propelled howitzer, it is an extremely bumpy history for the Indian weapons industry. In 1987, Indians imported 410 FH-77B 155mm/39-caliber howitzers from Swedish Bofors. Their advanced performance deeply impressed Indians. Therefore, India’s large-caliber artillery development plan for a long time was centered around the FH-77B platform. It even started to imitate the gun. As a result, it offended all manufacturers including the original manufacturer in various unreliable bidding and development processes. Later, the Indian military had to organize various research institutions and private enterprises in India to bid, and then these companies looked for foreign giants to cooperate in introducing technology. As a result, it fell into an unfavorable situation where it invested in several parallel projects at the same time but all failed. One of the losers was the ATAGS project.

The barrel of the MGS gun comes from the ATAGS gun project

The ATAGS self-propelled howitzer is a kind of artillery with auxiliary power. Strictly speaking, it is more appropriate to call it an auxiliary self-propelled artillery. Compared with the real self-propelled artillery, its mobility is relatively poor. The difficulty of development should be relatively low, but India’s low technical level and poor processing technology have held it back. The ATAGS plan started in 2013, and it was originally intended to be a short and fast project that would be put into service in 4 years. DRDO conducted a weapon verification of the artillery system on July 14, 2016, and the test was successful. The prototype gun fired the first round of live ammunition in Balasore, Odisha on December 14, 2016. In the 2017 test, ATAGS fired shells to a distance of 47.2 kilometers, and later again fired a maximum range of 48.074 kilometers, exceeding the maximum range of this type of NATO artillery system. ATAGS then continued to solve various problems that emerged, and conducted internal ballistic tests, summer use tests, and winter use tests in Balasore, Pokhran, and Sikkim respectively.

The gun was tested by users in September 2020 and suffered a major setback. The barrel burst, injuring four people and the gun was scrapped. In fact, the root cause of the problem of barrel bursting is probably due to the quality of India’s self-produced shells and the excessive modular charge. After all, the quality of domestic artillery shells manufactured by the Indian Ordnance Factory Board (OFB) is notorious for being unstable. Not only are various Indian self-developed artillery pieces suffering from this, but even imported high-end American M777s also suffer from barrel explosion accidents when firing Indian-made ammunition. On the one hand, the state-owned arsenals have low technical and management levels, cut corners, and zero on the other hand, they are bloated with backward systems and low efficiency. The Indian Ministry of Defense is also helpless with India’s state-owned weapons industry enterprises. Another reason is that compared with the 23-liter chamber of other howitzers, the proud Indians, in order to strive for the so-called maximum range, have increased the chamber volume to 25 liters without sufficient research, demonstration and testing, and the maximum modular charge has been directly increased from 6 to 7. This can certainly increase the amount of propellant, thereby increasing the range of the artillery, but it puts forward severe technical requirements for the artillery chamber itself, requiring it to be able to withstand greater peak pressure. Artillery material technology and chamber design are not the strengths of the Indian weapons industry. The pressure brought by the super-large chamber to the artillery material has evolved into a huge technical risk. However, the Indian side took a nonchalant attitude towards this technical issue. In November 2020, after only a short technical investigation of about two months, the Indian side easily approved the gun to be allowed to conduct further tests. On December 19, ATAGS tested again at the Balasore Shooting Range in Odisha and accurately hit the target. In June 2021, ATAGS successfully completed the test at an altitude of 4,600 meters. In 2022, the Indian Ministry of Defense is said to purchase 300 guns.

ATAGS self-propelled howitzer uses a 110 kW engine as auxiliary power, is equipped with an electronic wire-controlled steering system, supports high-end dual redundant encoders with electronically controlled hydraulic pumps and traction motors, and the 4x4 drive axle has independent suspension and articulation to adapt to the most difficult terrain. The maximum towing speed of the gun is 40 km/h, and it can travel 6 km autonomously at a speed of 18 km/h, with a turning diameter of 25 meters and a slope of 18 degrees. The gun’s march-to-combat state conversion is quite easy, taking only 1-2 minutes. The gun is deployed with a fully electric, ball screw linear actuator system, which has high reliability and high precision. It has the advantages of closed-loop servo control, high positioning accuracy and battery pack operation. It can automatically unfold and retract the large frame, bury and pull out the spade, shoot hydraulic locking, and aim at height and direction.

The gun’s loading system consists of a hydraulic ramming machine, a hydraulic pellet crane and a 3-round loading platform. First, the hydraulic arm lifts 3 rounds of pellets at a time and places them on the loading platform. The loader places the pellets in the ramming machine and automatically loads them into the gun barrel. The modular charge is transported and loaded by another ramming machine. This can speed up its firing rate. The system is driven by a military-grade 24VDC system, has three levels of redundancy, and uses no-return technology, which can be manually loaded on site in an emergency. The gun barrel can withstand a pressure of more than 550Mpa, with a burst firing rate of 5 rounds in 45 seconds, a rapid firing rate of 10 rounds in 2 minutes, and a continuous firing rate of 60 rounds in 60 minutes, that is, 1 round/minute. It can use a full-bore jujube shell to fire 5 rounds at the same time at 15 kilometers, and a single shell weighs 43 kg.

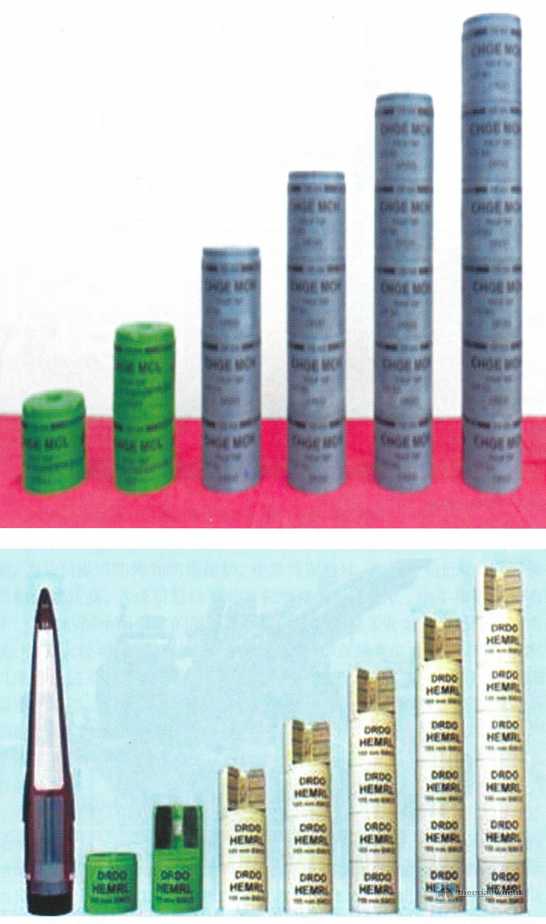

The gun can use the Indian-made dual modular propellant (BMCS) designed and developed by HEMRL for 155mm guns, with a suitable range table. Both modules have a combustible casing (CC) with necessary color codes and locking notches/grooves, including a cup-shaped body, a closing disc and an ignition tube. The Small Charge (LZ) is green in color and consists of modules No. 1 and No. 2, the LZ modules are filled with a fast-burning Single Base Propellant (SBP) containing NC as the main component to achieve silver-free combustion in the lowest area. The SBP pellets used have a cylindrical heptagonal tube shape and smaller dimensions (3.6 mm diameter x 5.7 mm length) while the Large Charge (HZ) modules are white in color and consist of modules No. 3, 4, and 5. Containing a slow-burning cold Tri-Base Propellant (TBP) with additional nitroglycerine (NG) and nitroguanidine (NQ) for higher energy, it is filled with rosette-shaped heptagonal tube pellets of larger dimensions (11 mm diameter x 22 mm length) for maximum load. They have different locking systems to avoid mixing LZ and HZ modules by mistake during any assembly process. The 45-caliber and 52-caliber barrels can also use additional No. 6 modules. In addition to primary ammunition such as ERFBBT and ERFB-BB, secondary ammunition such as HE, illumination or smoke can also be fired using BMCS. HEMRL has developed an automatic charge filling and assembly machine, in which the assembly of large charge modules can be completed in about 10 minutes, while manual assembly takes about 50 minutes. Of course, ATAGS can also use other modular charges.

ATAGS is equipped with a communication system, direct aiming equipment equipped with CCD, thermal imaging, laser rangefinder, barrel temperature sensor, propellant temperature sensor, recoil sensor, muzzle velocity radar, inertial navigation system and positioning system. The data are received by the ballistic computer on the left side of the gun and the parameters are calculated, and displayed on the gunner’s display/command module in the form of an easy-to-operate graphical user interface. The gunner can remotely control the gun through the joystick and select the combat mode through the keyboard and buttons. The gun is also compatible with India’s Shakti Artillery Combat Command and Control System (ACCCS).

Prospects for MGS truck gun

When changing to a truck gun, ATAGS will inevitably remove a large number of equipment to replace it with truck equipment, and the semi-automatic loading system also needs to be adapted. The barrel of the MGS 155mm 8x8 truck gun is 8.06 meters long. It uses a 25-liter chamber 465 MPa high-pressure barrel and a double-chamber muzzle brake with an efficiency of 35%. The tail mechanism is equipped with a screw-type gun door that opens upward, and the firing mechanism is an electric mechanical type. The gun has an elevation angle of 0 to +72 degrees, a horizontal angle of +/-25 degrees, 24 rounds of ammunition, and is equipped with the same number of dual-module charging systems (BMCS). The range of launching extended-range jujube shells is 35 kilometers, and the range of launching full-bore bottom-discharge extended-range shells is 45 kilometers, and the maximum range reaches 48.074 kilometers. Burst shooting is 3 rounds in 30 seconds, rapid shooting is 12 rounds in 3 minutes, the sustained rate of fire is 42 rounds/hour, and the single-shot shell is 43 kg. MGS can be ready to fire the first shell in 80 seconds. In less than 85 seconds, the truck gun can evacuate the position. The MGS 155mm 8x8 truck gun uses a semi-automatic loading system. First, the gun stops and deploys the hoe. The loader takes out a shell from the right side of the ammunition compartment and places it on the inclined ammunition rack on the side. Then a hydraulic arm on the side of the rear of the gun grabs the shell, rotates it and places it on the raised loader. The design of this grab arm is very similar to the design of the French "Caesar" 8x8 vehicle-mounted gun, but it is longer and has two joints removed to simplify the mechanism, but it requires the loader to be raised to cooperate. The shell rolls into the loader from the side, and then the loader descends and aims at the gun barrel. At this time, the loader places the white modular propellant on the other side, and the powder bucket rotates to aim at the gun barrel. This design is consistent with ATAGS, and the projectile and propellant are pushed into the gun barrel by the pusher. Then the screw hydraulic breech automatically locks and loads the primer, and finally aims and shoots. The advantage of this system is that it can still be loaded at any angle when the tail is very high. The disadvantage is that it becomes very difficult to load manually. Two small steps have to be installed on the tail for manual loading.

India claims that the truck gun has been tested for mobility and performance. Technical tests were conducted on the desert and off-road sections of NCAT (VRDE) and PFFR. Shooting tests were also conducted at the Pokhran Range (PFFR) to evaluate the system’s range, shooting consistency, firing range and direct firing capabilities. Judging from the shooting video, the vehicle is still very stable when shooting at the highest angle. Moreover, for the high-altitude long-range shooting capabilities that Indians urgently need, the MGS truck gun’s rapid deployment and adjustment function and semi-automatic loading system are very helpful for the crew to save energy and speed up the firing rate.

However, from the design point of view, the MGS truck gun is obviously still unreasonable. On the one hand, a large number of equipment are piled up at the rear of the vehicle, and the gun design is not streamlined enough, which is complicated and cumbersome, and the gun tail is too high. The large amount of equipment piled up at the gun tail means that the overall quality of the truck gun is not balanced enough, which will have an adverse effect on the entire system when maneuvering on the road, especially when turning.

At the same time, the operation of the MGS vehicle-mounted gun is also quite inconvenient, and the structure of the designed semi-automatic loader is too complicated, which can easily reduce the reliability of the system and increase the failure rate of the system.

On the other hand, due to the use of 8x8 chassis and non-retractable semi-automatic loader, the vehicle body is too long, which seriously affects the passability, the configuration is too large, and the vehicle weight exceeds the standard. The 30-ton vehicle weight can only be transported by C-17, resulting in poor strategic mobility, and it has to compete with the K9 self-propelled artillery for precious large transport aircraft transportation capacity.

The European solution is to directly integrate the spade and the loading platform together, integrate a large number of equipment into the vehicle, and the tail of the gun is very simple. China’s standard truck gun further simplifies the design, further shortens the length of the vehicle, and further improves the flexibility and mobility of the system. Considering that the MGS truck gun is aimed at the mountain combat environment in the Sino-Indian border area, where the roads are long and rugged, and there are many bends due to the large height difference of the terrain, this brings great difficulties and challenges to the mobility of the MGS truck gun. I am afraid that only in actual application will the Indian Army understand the importance of reasonable adaptability and targeted design for weapon systems.